A push-to-release pen

A pen holder and pen holder technology, applied in printing, writing utensils, writing parts and other directions, can solve the problems of complex structure of pressing pen, and achieve the effects of simple structure, convenient implementation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

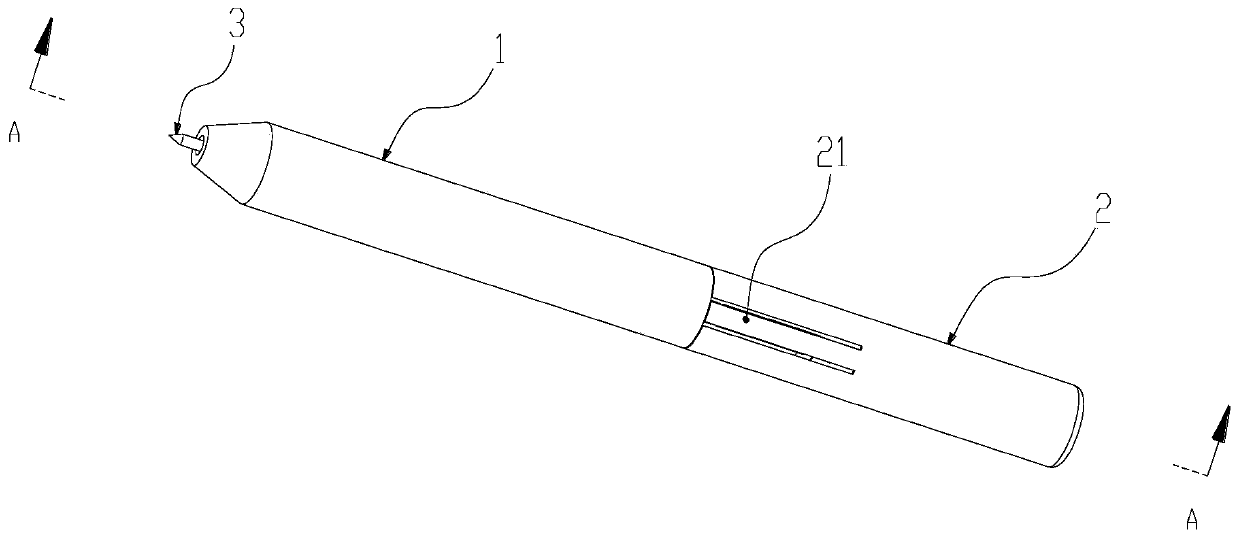

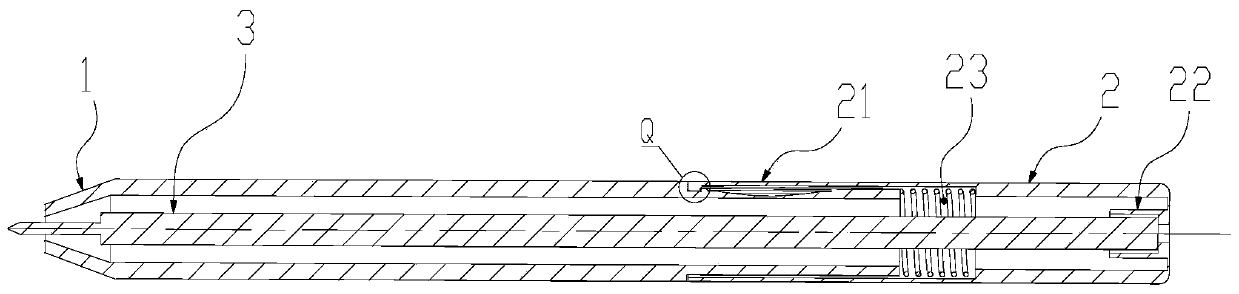

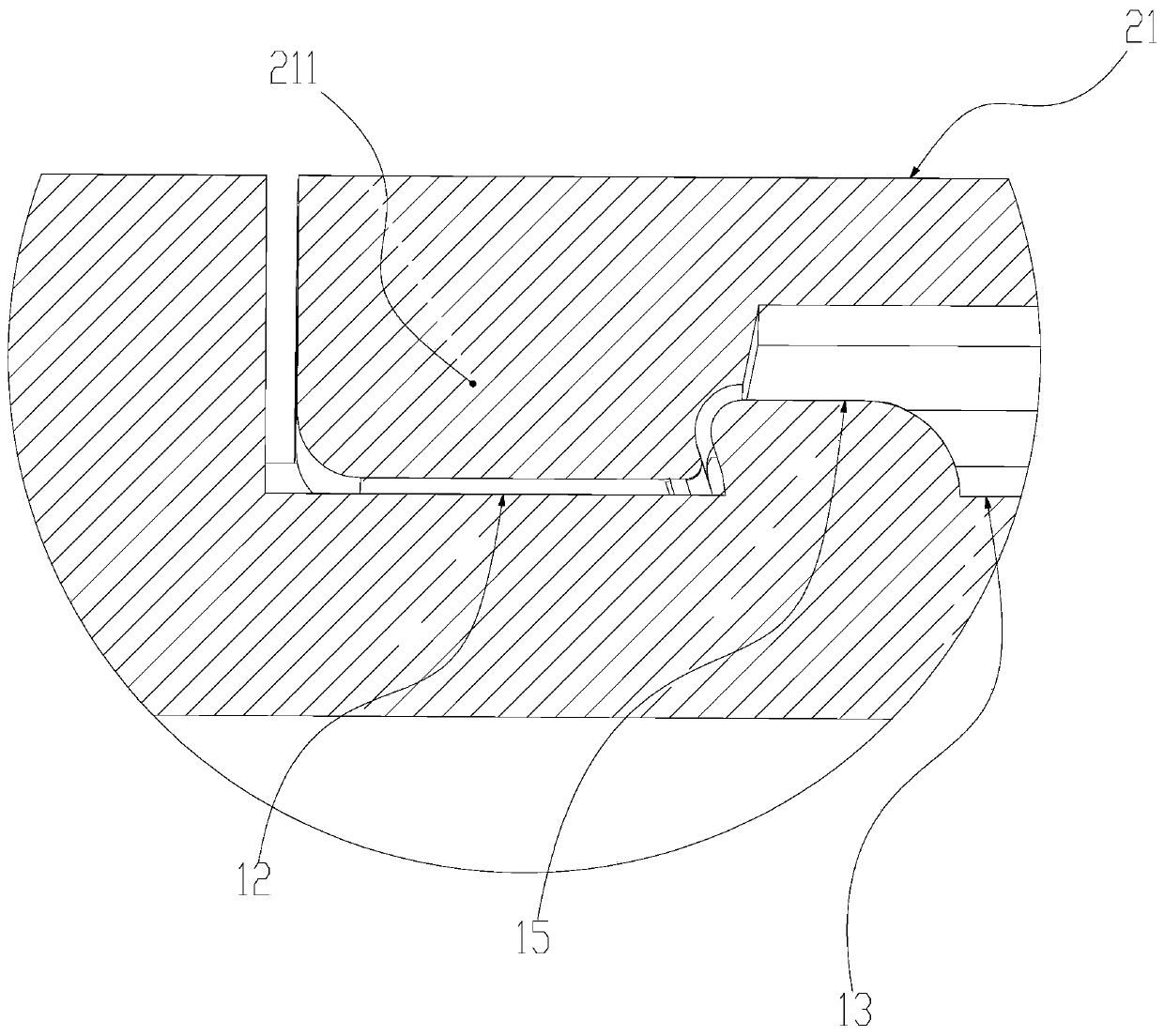

[0038] Such as Figures 1 to 4 A push-and-release pen shown includes a front pen holder 1, a rear pen holder 2, a pen core 3 and an elastic member. Wherein, the above-mentioned front pen holder 1 has a nib end and a sleeve end; as Figure 4 As shown, the socket end is an extension part whose outer diameter of the main body is smaller than that of the front penholder 1 body, and a fixing groove 12 and a sliding groove 13 are arranged on the circumferential outer wall of the socket end. The fixing groove 12 is arranged near the end of the nib, the inner end of the sliding groove 13 is connected to the fixing groove 12, and the outer end of the sliding groove 13 is a groove connected to the outer end surface of the sleeve end through a bending groove.

[0039]The above-mentioned rear pen holder 2 has a pen core fixing groove 22 and a movable inner chamber 23, and the socket end of the front pen holder 1 and the movable inner chamber 23 of the rear pen holder 2 are socketed with ...

Embodiment 2

[0049] Such as Figures 5 to 7 A push-and-release pen shown includes a front pen holder 1, a rear pen holder 2, a pen core 3 and an elastic member.

[0050] The above-mentioned front penholder 1 has a nib end and a socket end, and a fixing groove 12 and a sliding groove 13 are arranged on the above-mentioned socket end. Rear pen container 2, described rear pen container 2 has pen core fixing groove 22 and movable inner cavity 23, the socket end of described front pen holder 1 and the movable inner cavity 23 of rear pen container 2 are mutually socketed, and described rear pen container 2 is provided with There is an elastic extrusion fixing part 21, and the elastic extrusion fixing part 21 is also provided with a matching protrusion 211, and the matching protrusion 211 is matched with the fixing groove 12, and the elastic extrusion fixing part 21 is extruded by an external force Afterwards, its structure will be deformed inward, causing the matching protrusion 211 to lift wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com