Floor type multi-purpose variable-section lifting beam

A variable cross-section, multi-purpose technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of internal force changes of different structures, inconvenient landing, etc., and achieve the effect of optimizing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

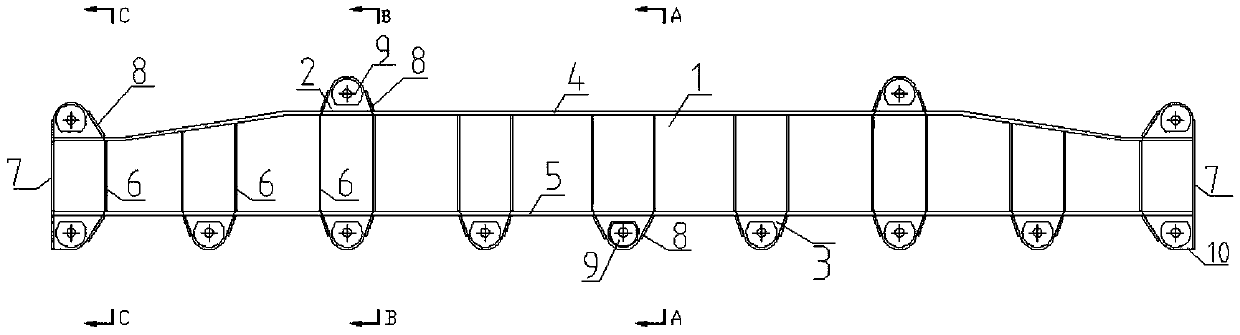

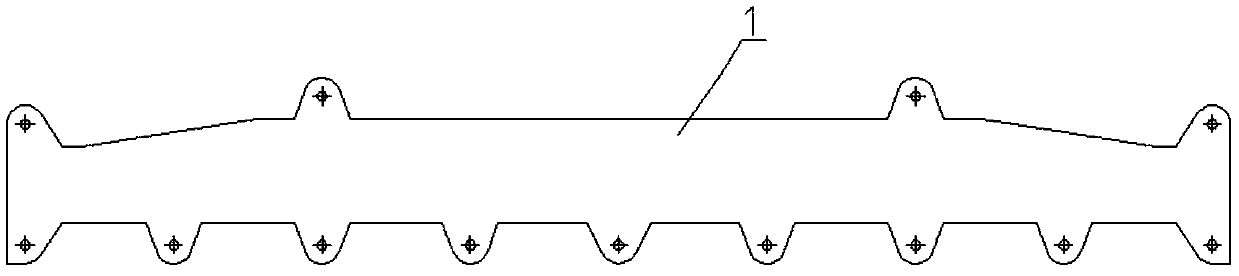

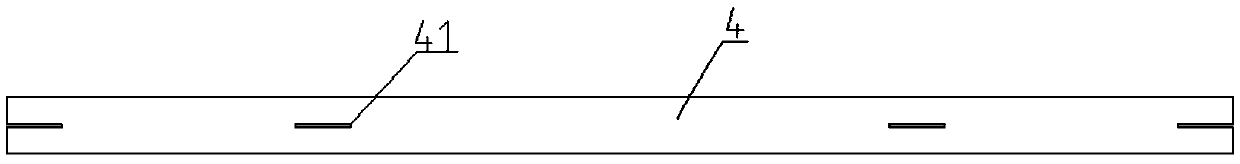

[0033] Such as figure 1 and figure 2 As described above, a floor-standing multi-purpose variable-section hanging beam, the vertical section of the hanging beam along the length direction is a variable section with a wide middle and narrow ends, and the variable-section hanging beam includes: a vertically arranged main web 1, a horizontally arranged top Panel 4 and bottom panel 5, a plurality of partitions 6 vertically spaced between top panel 4 and bottom panel 5; main web 1, top panel 4, and bottom panel 5 have the same length direction, and main web 1 and top panel 4 and the bottom panel 5 are connected together to form an I-shaped structure; there is a top lug 2 above the top panel 4, and a bottom lug 3 below the bottom panel 5; the two sides of the top panel 4 and the bottom panel 5 have vertical connections Both ends of the support panel 7; the top lug 2 and the bottom lug 3 also have lug brackets 8 on both sides, the center of the lug has a hoisting hole, and the hoist...

Embodiment 2

[0044] Such as figure 1 and figure 2 As described above, a floor-standing multi-purpose variable-section hanging beam, the vertical section of the hanging beam along the length direction is a variable section with a wide middle and narrow ends, and the variable-section hanging beam includes: a vertically arranged main web 1, a horizontally arranged top Panel 4 and bottom panel 5, a plurality of partitions 6 vertically spaced between top panel 4 and bottom panel 5; main web 1, top panel 4, and bottom panel 5 have the same length direction, and main web 1 and top panel 4 and the bottom panel 5 are connected together to form an I-shaped structure; there is a top lug 2 above the top panel 4, and a bottom lug 3 below the bottom panel 5; the two sides of the top panel 4 and the bottom panel 5 have vertical connections Both ends of the support panel 7, such as figure 1 and Figure 8 As shown; there are lifting bracket brackets 8 on both sides of the top lifting lug 2 and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com