A secondary aqueous dispersion of hydroxyl-containing polyacrylate and its preparation method

A hydroxyacrylic acid, secondary dispersion technology, applied in the field of coatings, can solve the problems of difficult emulsification, low reactivity, high dispersion viscosity, etc., and achieve the effect of good hydrophilic dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

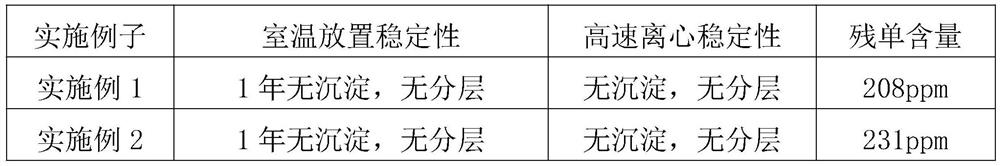

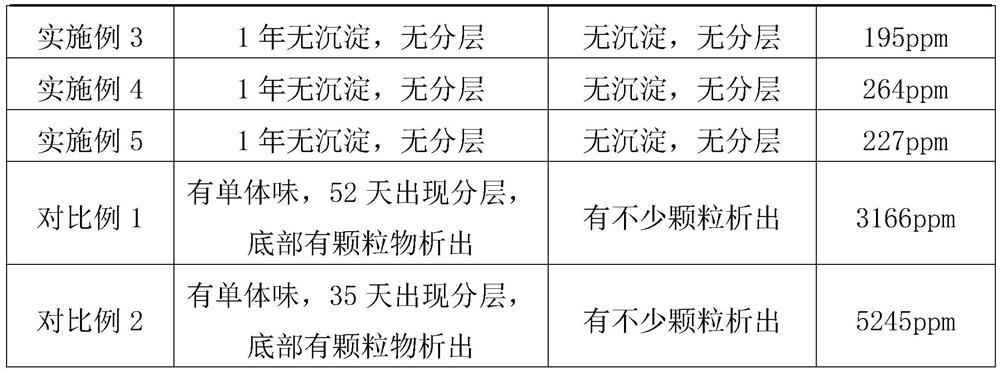

Examples

Embodiment approach

[0039] A method for preparing a secondary dispersion of aqueous hydroxyl-containing acrylic resin, characterized in that: it is mainly prepared from the following components by mass according to the following steps: 1-3 parts of co-solvent, 0.5-2 parts of carboxyl-containing monomer, 5-15 parts of hydroxyl-containing monomers, 15-35 parts of acrylate monomers, 5-15 parts of vinyl monomers, 0.5-1 parts of initiators, 0.5-2 parts of neutralizers, 48-55 parts of deionized water,

[0040] Including the following preparation steps:

[0041] (1) Mix carboxyl-containing monomers, hydroxyl-containing monomers, acrylate monomers, and vinyl monomers evenly to form a mixed monomer, then continuously feed nitrogen into the reactor to remove moisture and air, and then add co-solvent , stir and heat up to the specified temperature, start dropwise adding the first part of the mixed monomer and the first part of the initiator, drop it within 2 to 3 hours, keep it warm for 0.5 to 1 hour, the f...

Embodiment 1

[0058] Feed nitrogen into the four-necked reaction flask A, add 200g of 100# solvent oil into the reaction flask, stir and raise the temperature to 140-150°C, start to add dropwise 144g of hydroxyethyl acrylate, 151.2g of methyl methacrylate, 54g of The mixture of butyl acrylate, 78g of n-butyl methacrylate, 154.8g of styrene and 9g of tert-butyl peroxy-3,5,5-trimethylhexanoate, the dropping rate is controlled uniformly, and the dropping is completed within 3 hours After dropping, keep warm for 45 minutes and start to drop 31g of acrylic acid, 96g of hydroxyethyl acrylate, 100.8g of methyl methacrylate, 36g of butyl acrylate, 52g of n-butyl methacrylate, 103.2g of styrene and 6g of tertiary Butyl peroxy-3,5,5-trimethylhexanoate, drop it at a constant speed within 2 hours, keep it warm for 1.5 hours, distill 100# solvent oil under reduced pressure, leave 30g, fill it with nitrogen; take another Four-necked reaction bottle B, add 1000g deionized water and 33g dimethylethanolamin...

Embodiment 2

[0061] Inject nitrogen into the four-necked reaction flask A, add 200g of butyl acetate / xylene mixture into the reaction flask, stir and raise the temperature to 140-150°C, and start to drop 182g of hydroxypropyl acrylate and 196g of methyl methacrylate ester, 42g butyl acrylate, 70g n-butyl methacrylate, 126g styrene, 56g tert-ethylene carbonate VeoVa 9 mixture and 12.6g of di-tert-amyl peroxide, control the rate of addition uniformly, drop in 2.5h Finished, keep warm for 30 minutes after dripping, start to add 34g of acrylic acid, 78g of hydroxypropyl acrylate, 84g of methyl methacrylate, 18g of butyl acrylate, 30g of n-butyl methacrylate, 54g of styrene, 24g of tertiary vinyl carbonate VeoVa The mixture of 9 and 5.4g of di-tert-amyl peroxide were dripped at a constant speed within 2h, kept warm for 2h, and the solvent was distilled off under reduced pressure, leaving 30g, filled with nitrogen; take another four-necked reaction flask B, add 1000g deionized water and 36g dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com