Operation and maintenance auxiliary tag generation method and system

A labeling and operation and maintenance technology, applied in the direction of instruments, character and pattern recognition, data processing applications, etc., can solve the problems of lack of effective collection and accumulation of data, high cost, and difficulty in meeting operation and maintenance efficiency, so as to improve operation and maintenance efficiency and alleviate O&M heavy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further specifically described below through specific embodiments in conjunction with the accompanying drawings.

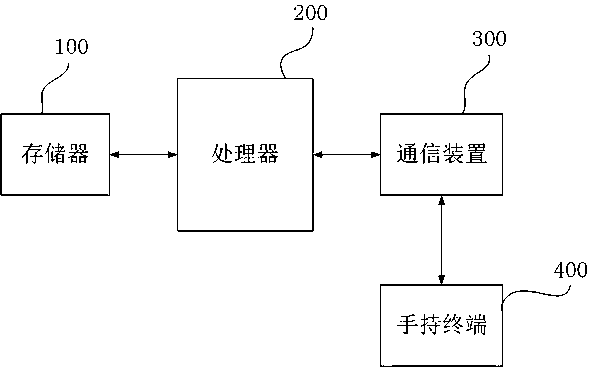

[0020] Such as figure 1 As shown, it is a structural diagram of the operation and maintenance auxiliary label generation system. The communication device 300 and the memory 100 are connected to the processor 200. The handheld terminal 400 is connected to the processor 200 through the communication device 300. The handheld terminal 400 accepts the data input by the operation and maintenance personnel and The data is transmitted to the processor 200. During on-site maintenance by the operation and maintenance personnel, the handheld terminal 400 receives the device information and label settings, and sends the information and labels back to the data server.

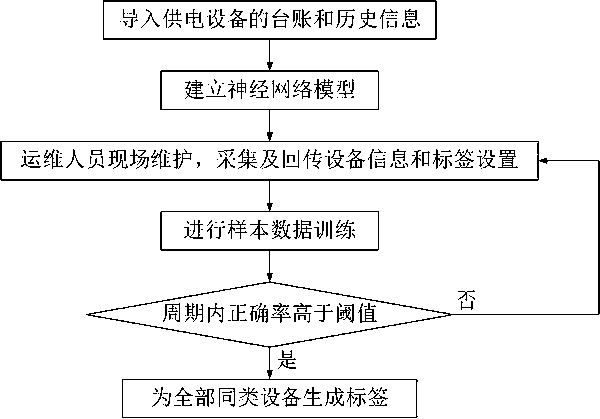

[0021] Such as figure 2 As shown, it is a flow chart of the generation method of the operation and maintenance auxiliary label, including the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com