Aboveground logistic transportation pipe

A transportation pipeline and logistics technology, applied in the direction of roads, roads, building structures, etc., can solve the problems of reducing the bearing capacity and service life of the pipeline structure, corrosion of the pipeline structure, low transportation efficiency, etc. Erosion and destruction, stable and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments.

[0032] The structure of an aboveground logistics transportation pipeline in this embodiment is:

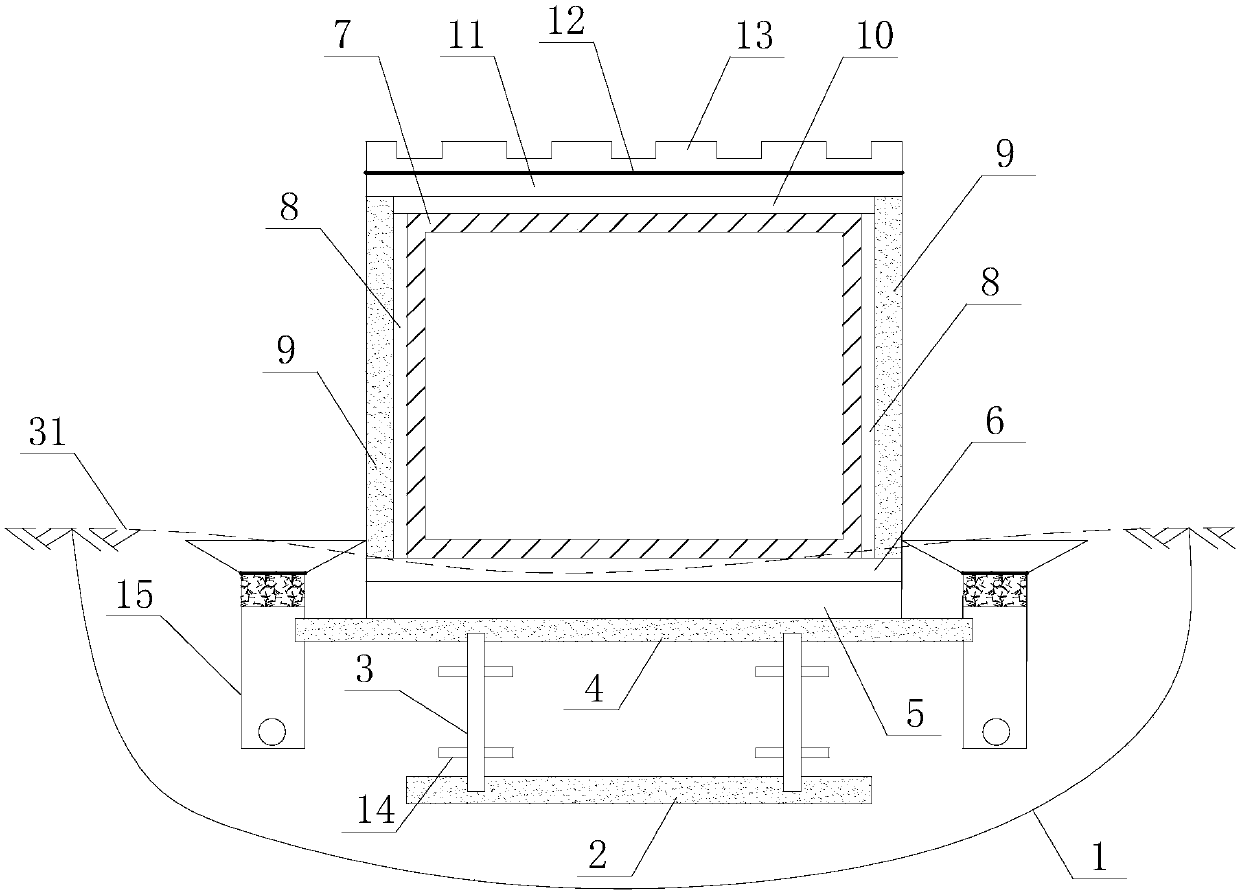

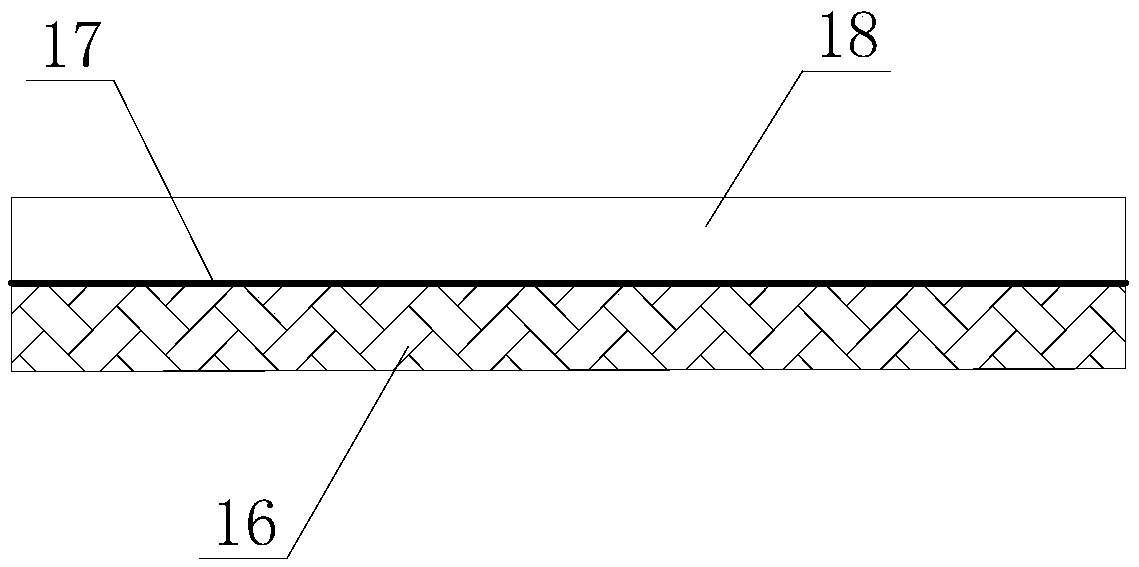

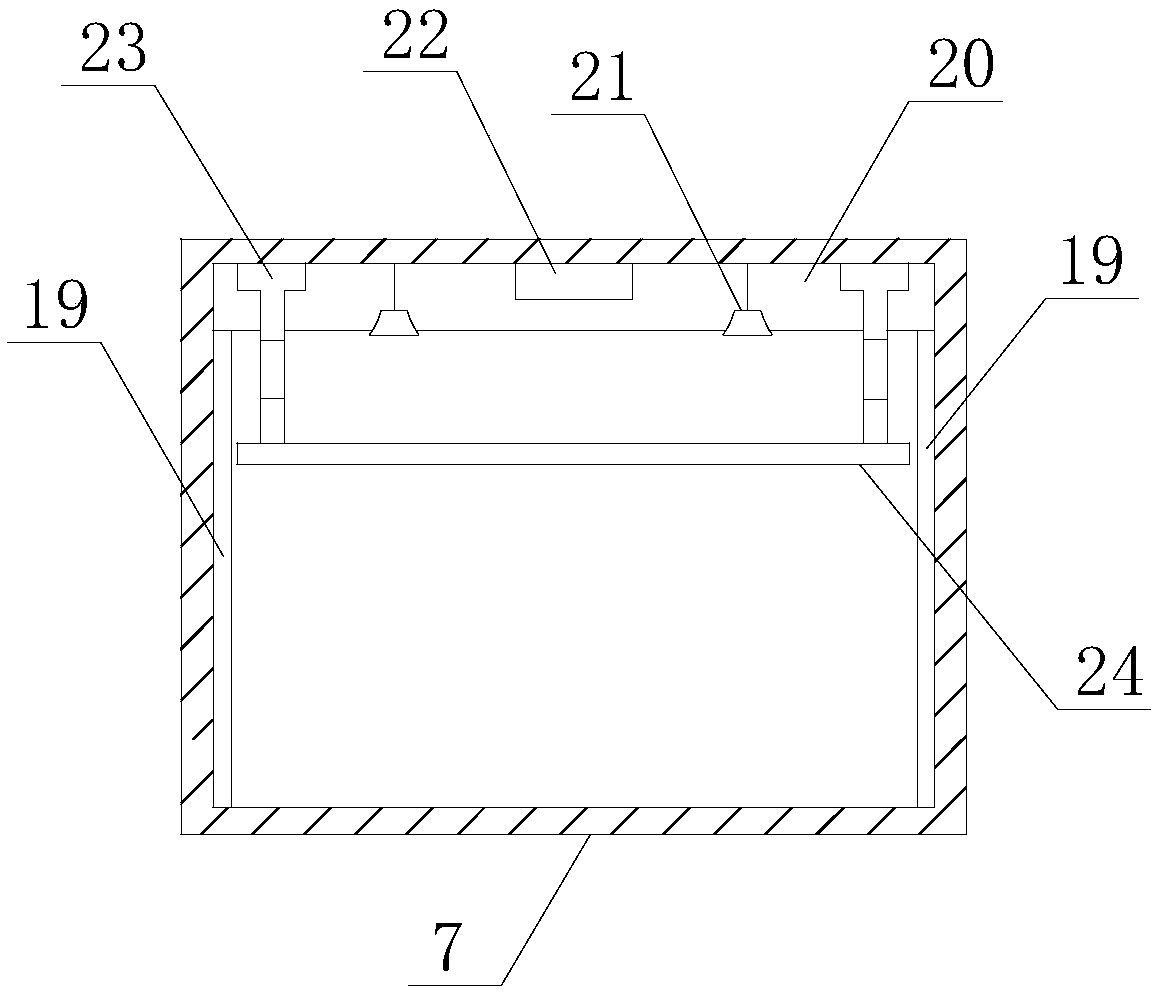

[0033] See figure 1 In this embodiment, the pipeline includes a backing plate 2 set in the soil foundation 1, a supporting column 3 provided on the backing plate 2, a connecting plate 4 set on the top of the supporting column 3, and a connecting plate 4 arranged in sequence The composite cushion 5, the lower bearing plate 6 and the tube core 7, the waterproof plate 8 provided on both sides of the tube core 7, the side protection plate 9 provided on one side of the waterproof plate 8, and the tube core 7 The impermeable board 10, the upper bearing plate 11 provided on the impervious board 10, the waterproof geotextile 12 provided on the upper bearing plate 11, and the planting board 13 provided on the waterproof geotextile 12.

[0034] In this embodiment, the support column 3 is a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com