Wood grain cross grain supplementation device

A technology of horizontal grain and wood grain, which is applied in the field of imitation wood grain and wood grain horizontal grain supplementary device, which can solve the problems of unstable graining effect and low overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

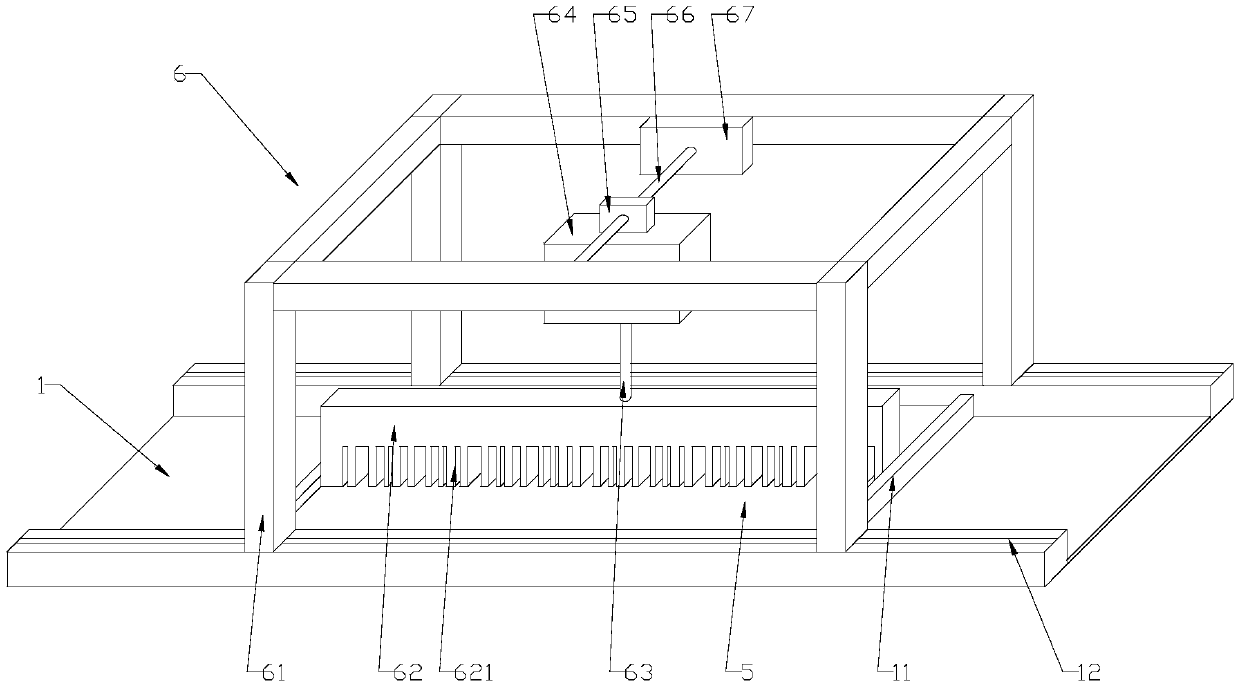

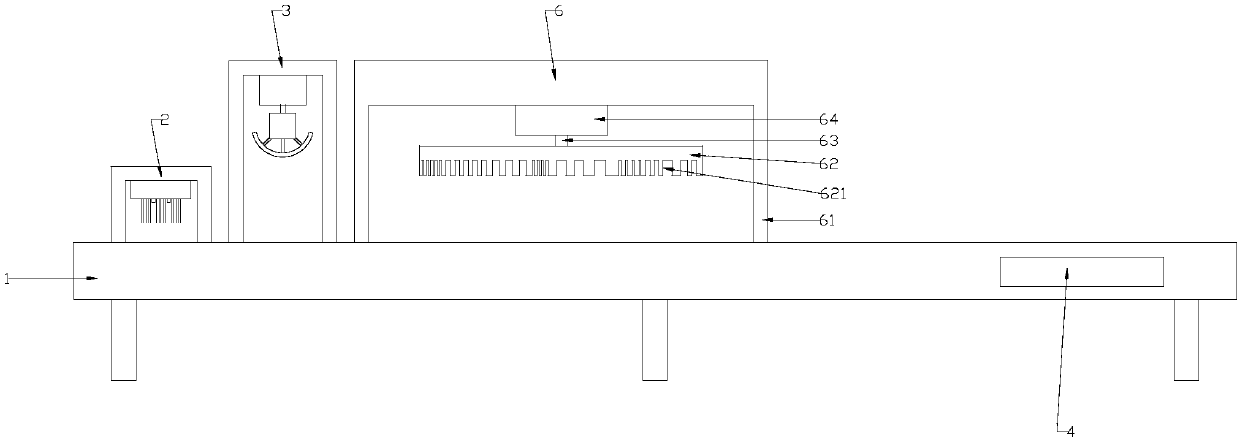

[0015] refer to figure 1 and figure 2 , a kind of wood grain cross-grain replenishment device according to the present invention includes a conveyor belt 1, a control unit 4 and a cross-grain unit 6, and the cross-grain unit 6 includes a support frame 61, a rubber brush plate 62, a cylinder 64, a screw nut 65, a screw rod 66 and a motor 67, the support frame 61 is slidably connected to the slideway 12 on the top of both sides of the conveyor belt 1 through the slider at the bottom, the motor 67 and the screw rod 66 are fixed on the top of the support frame 61 and driven to be installed on the screw rod 66 The screw nut 65 on the top moves horizontally perpendicular to the conveying direction of the conveyor belt 1. The cylinder 64 is fixed on the screw nut 65 and connected with the rubber brush plate 62 through the telescopic rod 63. The bottom surface of the rubber brush plate 62 is provided with several A brush groove 621, the belt body surface of the conveyor belt 1 is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap