Pouring quantitative liquid dispenser with hydraulic compensation function

A quantitative liquid and dispenser technology, applied in the direction of closing, packaging, transportation and packaging, etc., can solve the problems of inconvenient operation, poor washing effect, waste, etc., to improve accuracy and stability, and reduce the effective liquid inlet area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

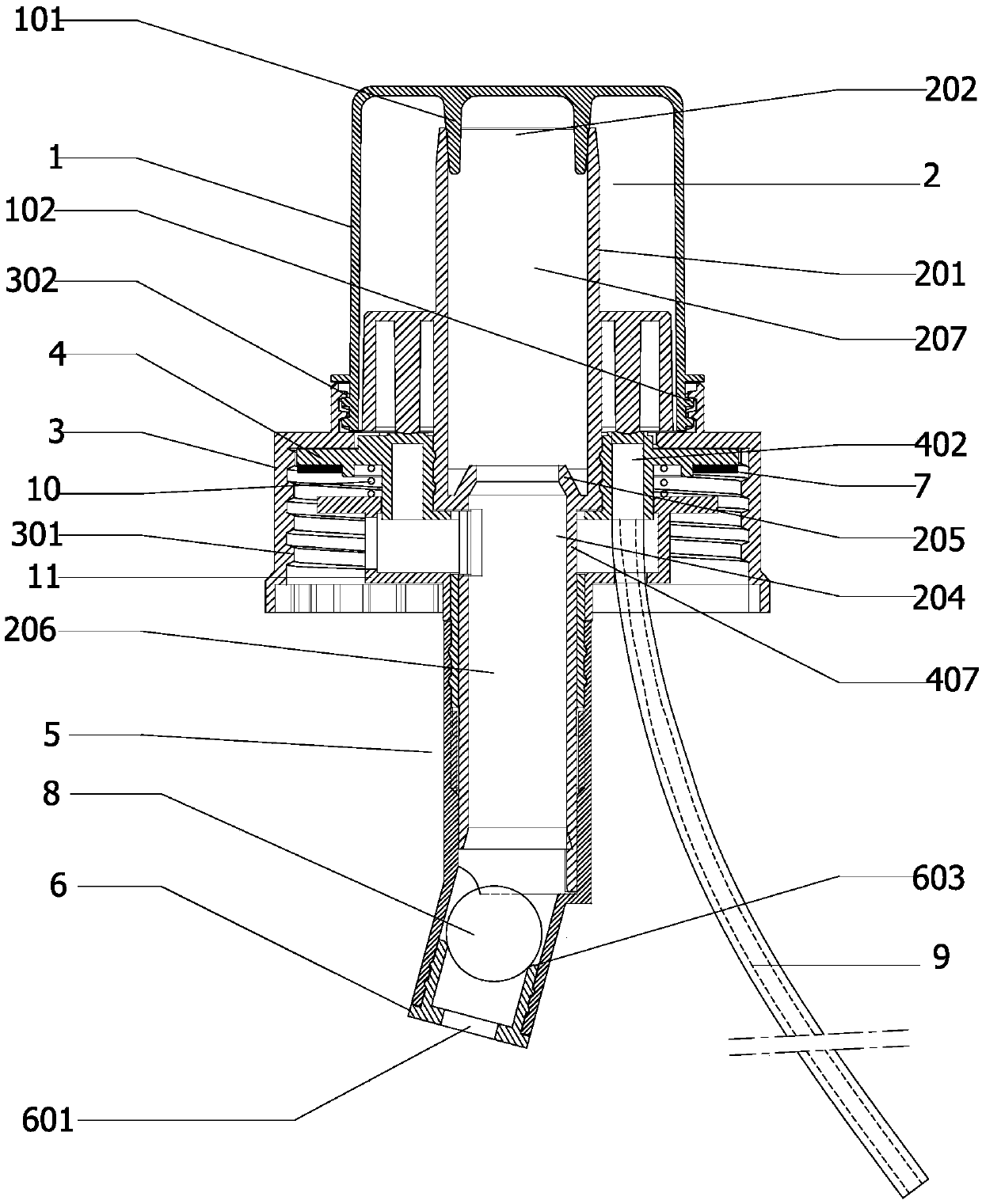

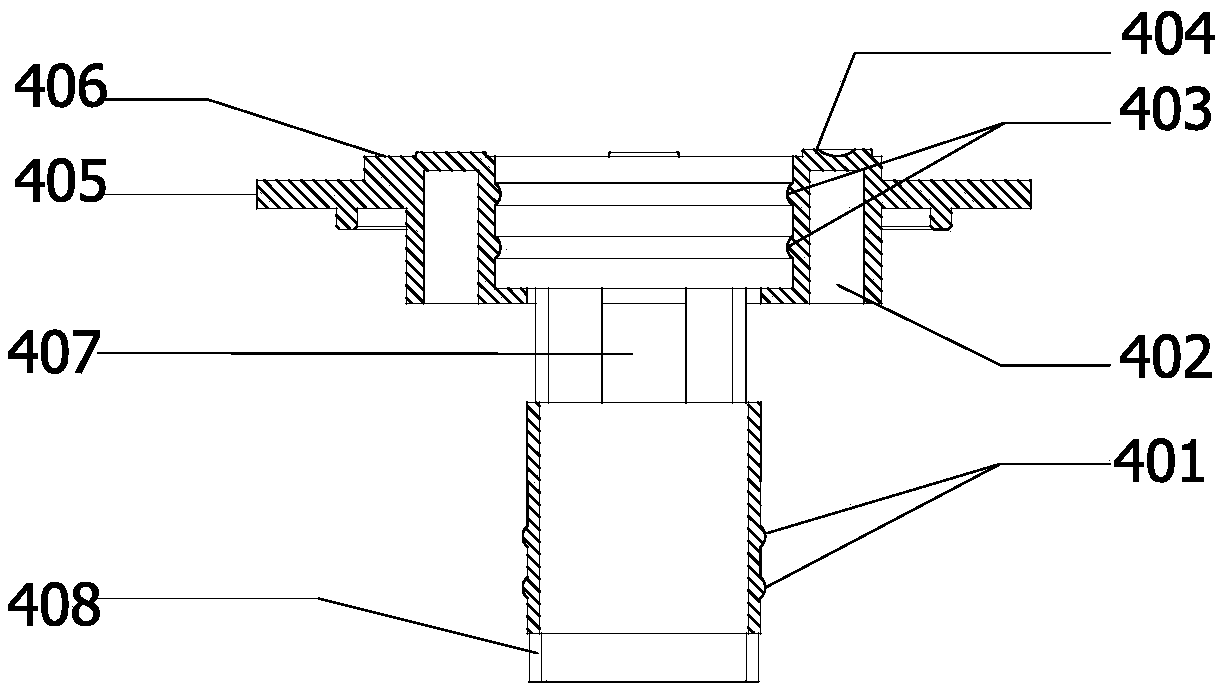

[0074] Such as Figure 1 to Figure 27 As shown, a pouring quantitative liquid dispenser with hydraulic compensation function, the pouring quantitative liquid dispenser with hydraulic compensation function includes a sealing cover 1, a valve body 2, a fixed sleeve 4, a bottle cap 3, and an end sleeve 6 , hydraulic compensation device, sphere 8 and intake pipe 9;

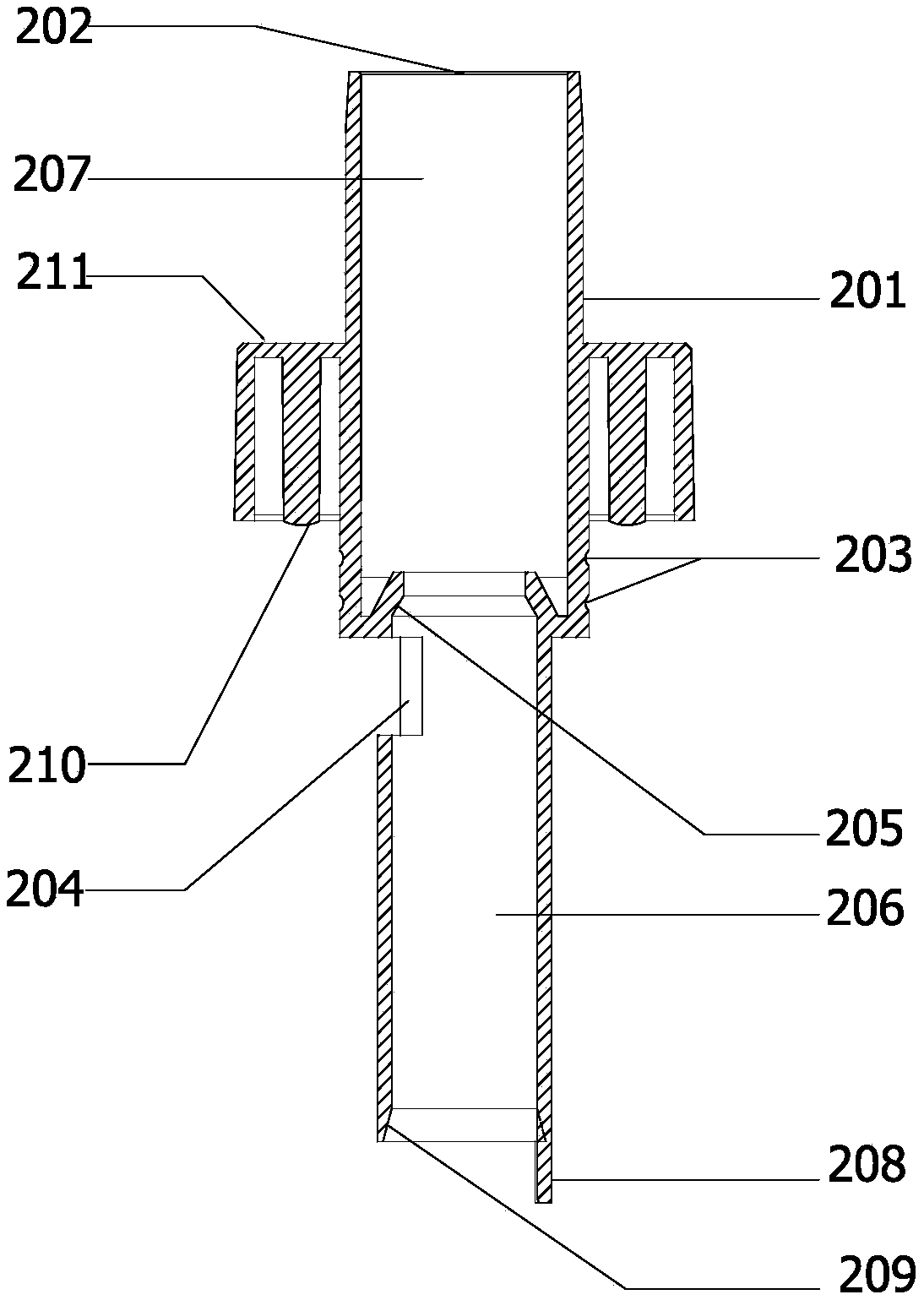

[0075] Such as figure 2 As shown, the valve body 2 is divided into two parts, the upper part is a liquid outlet pipe 201, the lower part is a damping chamber 206, the inside of the liquid outlet pipe 201 is a liquid outlet chamber 207, and the top is provided with a liquid outlet pipe connected to the liquid outlet chamber 207. The port 202 is provided with an annular valve body flange 211 on the outside; a ball 8 sealing seat 205 is provided between the liquid outlet chamber 207 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com