Tubular gas-liquid distributor

A gas-liquid distributor and tube-type technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of variable gas-liquid distribution in distribution plates, small operation elasticity of the distributor, and large fluctuation range of gas-liquid volume. , to achieve the effect of large operating flexibility, improving strength, and avoiding non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

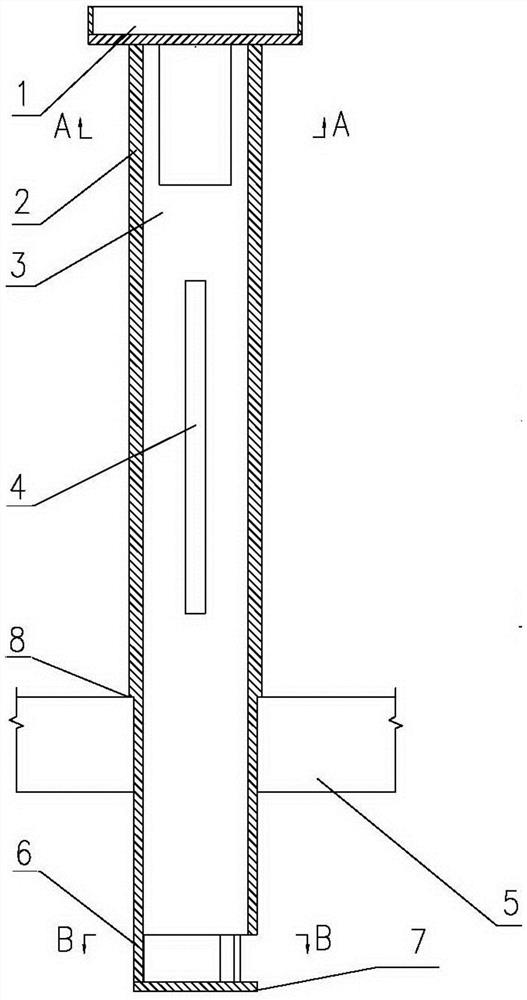

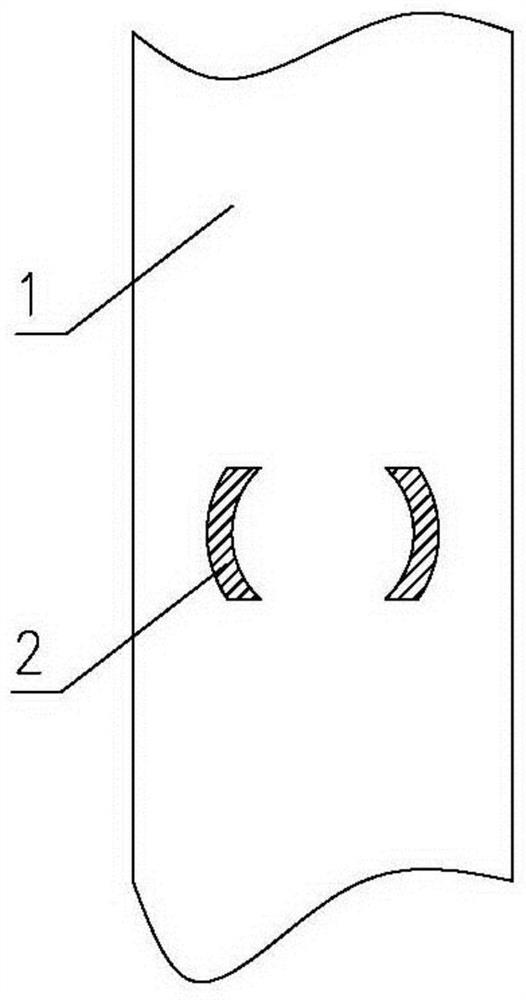

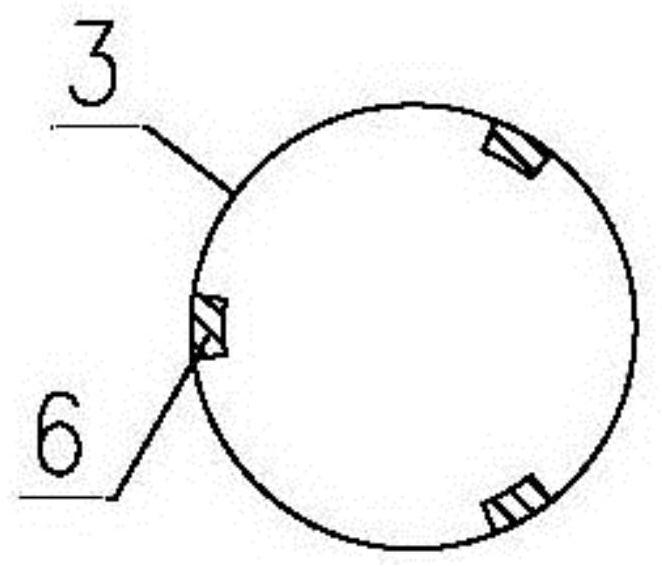

[0020] figure 1 It is a structural schematic diagram of the present invention. In the figure, the tubular gas-liquid distributor of the present invention includes an overflow weir 1, an overflow weir support 2, a central pipe 3, a slit 4, a distribution plate 5, a broken flow plate support 6, a broken flow plate 7 and an annular Step 8. The overflow weir 1 is a long strip rectangular tank, arranged in parallel with each other at intervals, such as Figure 4 shown. Weir supports 2 such as figure 2 As shown, the broken flow plate support 6 is as image 3 shown.

[0021] The central tube 3 is cylindrical, and its wall thickness can be 2-6mm, such as 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 5.5mm or 6mm.

[0022] The central pipe 3 can be configured to include a first pipe section and a second pipe section connected to each other, the first pipe section is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com