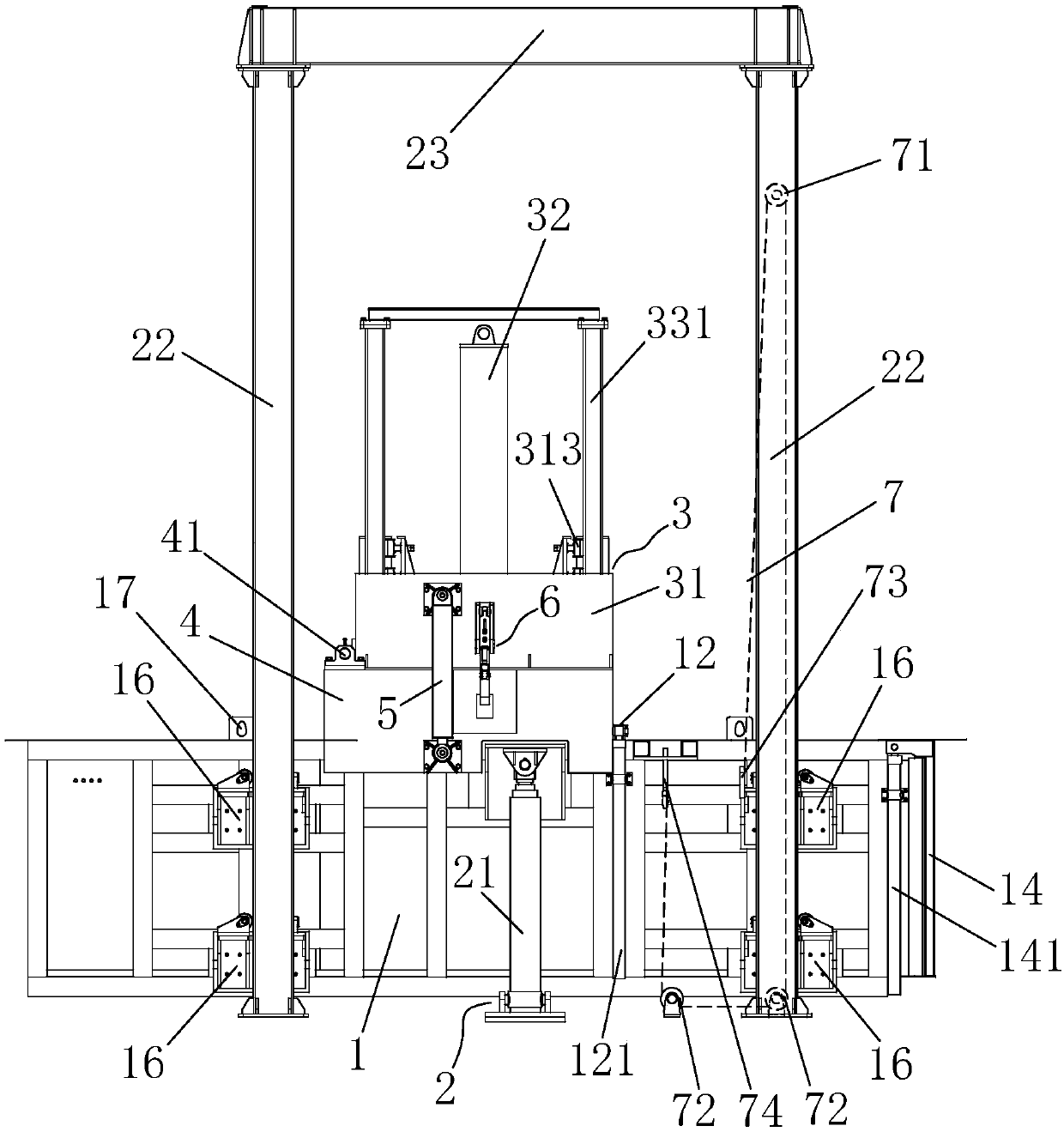

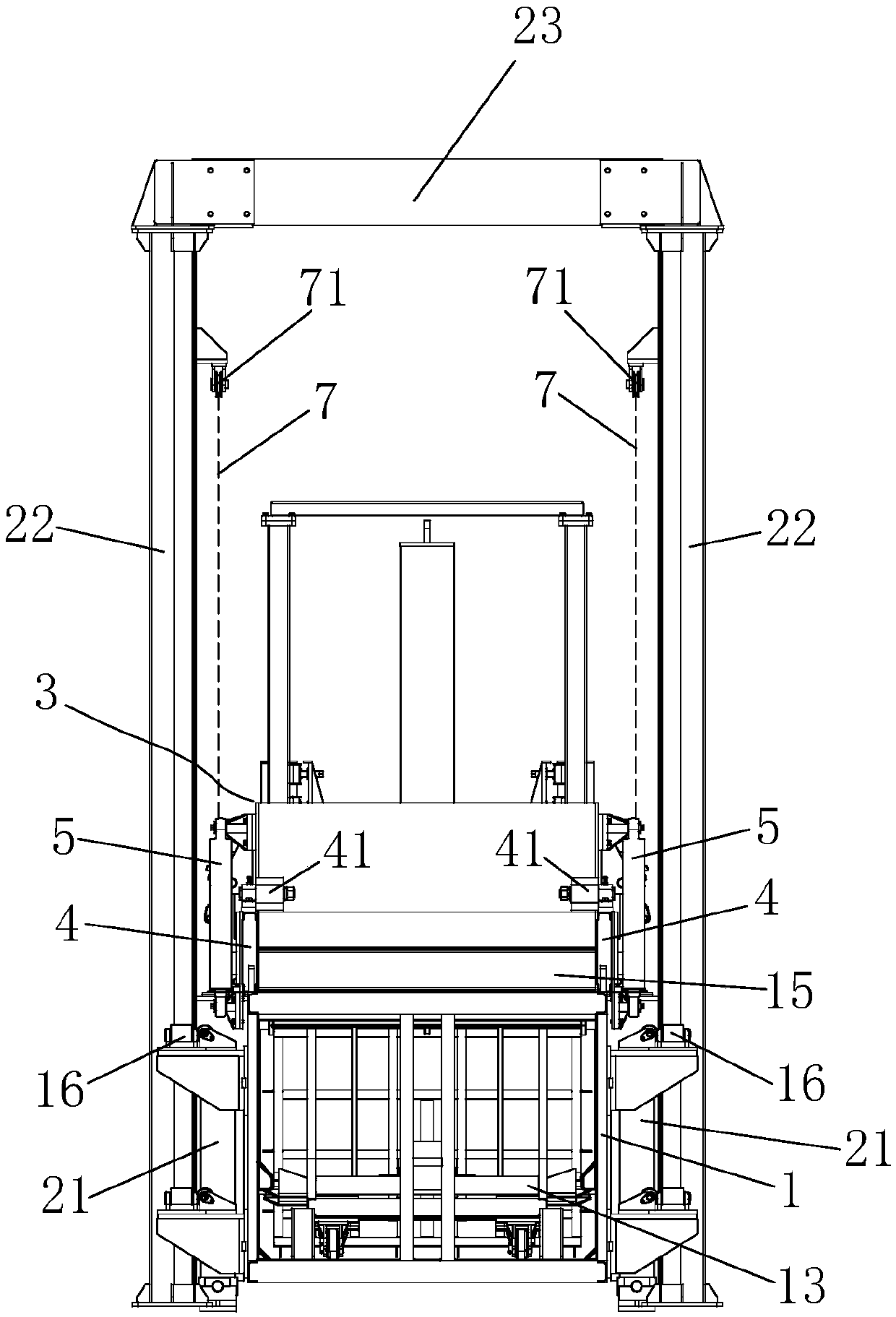

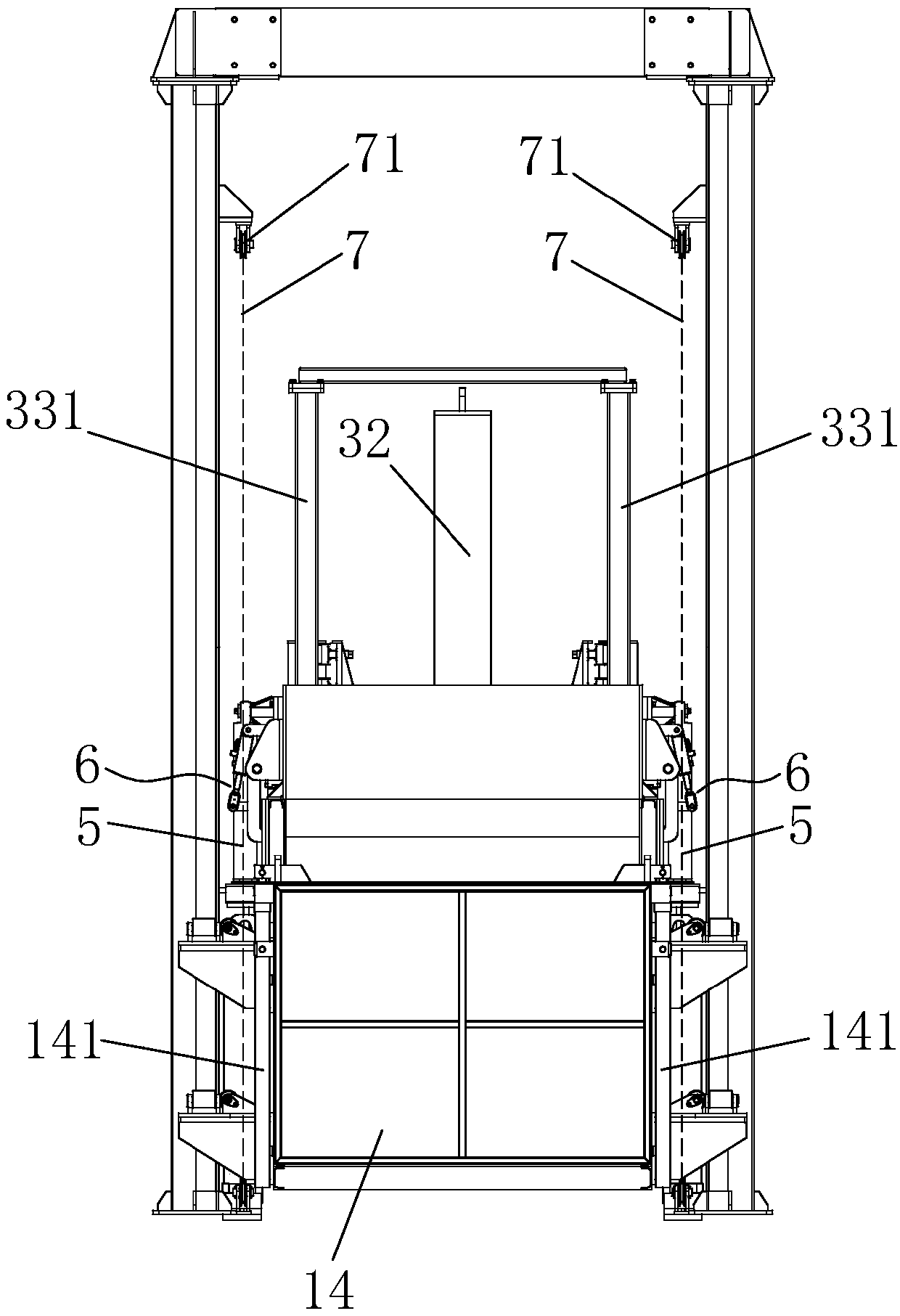

Vertical-compressing machine for garbage with pressing head capable of being overturned

A compressor and garbage technology, which is applied in trash cans, garbage conveying, garbage collection, etc., can solve the problems of small turning angle, occupying the ground installation position, unfavorable garbage dumping, etc., and achieve the effect of reducing the installation height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] Embodiment two, Figure 8 As shown, a garbage vertical compressor whose pressure head can be turned sideways is different from Embodiment 1 in that a compressible buffer 8 is installed on the upper end of each convex portion 4 near the outer gate 14, When compressing the garbage, the upper end of the buffer 8 is against the bracket 31 . The collision between the bracket 31 and the two protrusions 4 can be buffered by the two buffers 8, and the reliability of the locking state of the two sets of locking mechanisms can also be enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com