Two-way expanding, taking and placing device

A two-way unfolding, pick-and-place device technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of complex structure, large volume, large space occupation, etc. The effect of a wide range of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

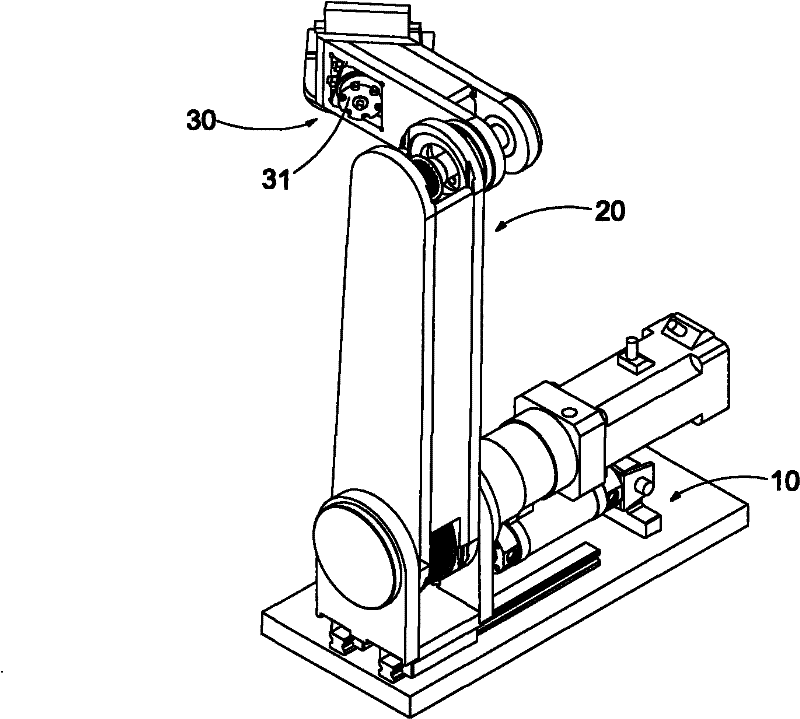

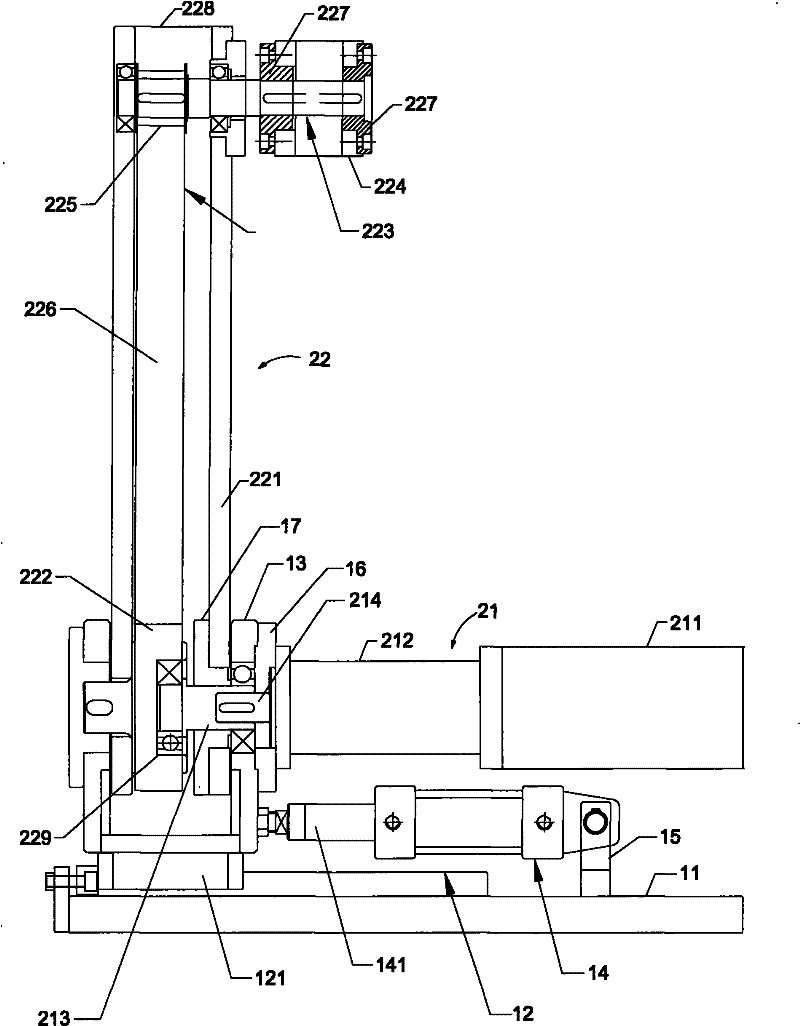

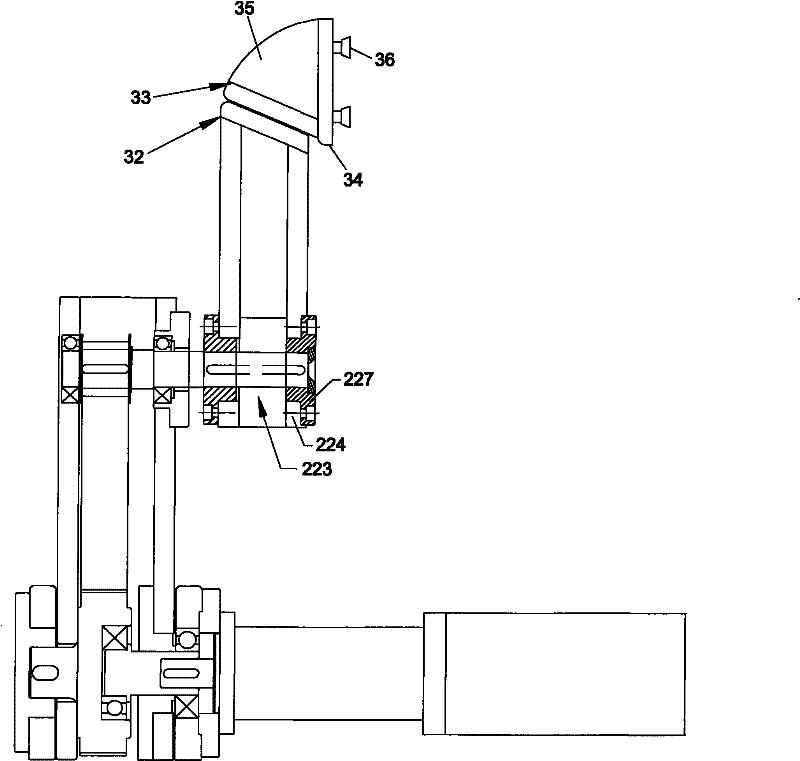

[0029] like Figure 1 to Figure 6 Shown is a kind of preferred concrete implementation example of the present invention, two-way unfolding pick-and-place device, as figure 1 As shown, it includes a forward and backward unit 10, a two-way unfolding unit 20 and a rotating pick-and-place unit 30, wherein the two-way unfolding unit 20 is arranged on the advance-and-retreat unit 10, and the rotating pick-and-place unit 30 is set on the two-way unfolding unit 20, The forward and backward unit 10 drives the two-way expansion unit 20 to move linearly, and the two-way expansion unit 20 drives the rotary pick-and-place unit 30 to a suitable position for picking and receiving. Take it out and place it horizontally on the conveyor belt or subsequent processing equipment.

[0030] The advancing and retreating unit 10 includes a linear slide rail 12, a seat plate 13, and an advancing and retreating linear cylinder 14. The linear slide rail 12 is provided with a slider 121, the seat plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com