Lens processing equipment and processing method thereof

A technology of processing equipment and processing methods, which is applied in other household appliances, household appliances, solar thermal power generation, etc., can solve the lack of structural thickness uniformity and the process method of air bubble elimination, the lack of thickness uniformity control measures, and the inability to do To solve problems such as product uniformity, to achieve the effect of ensuring the amount of glue, the best visual effect, and the uniformity of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

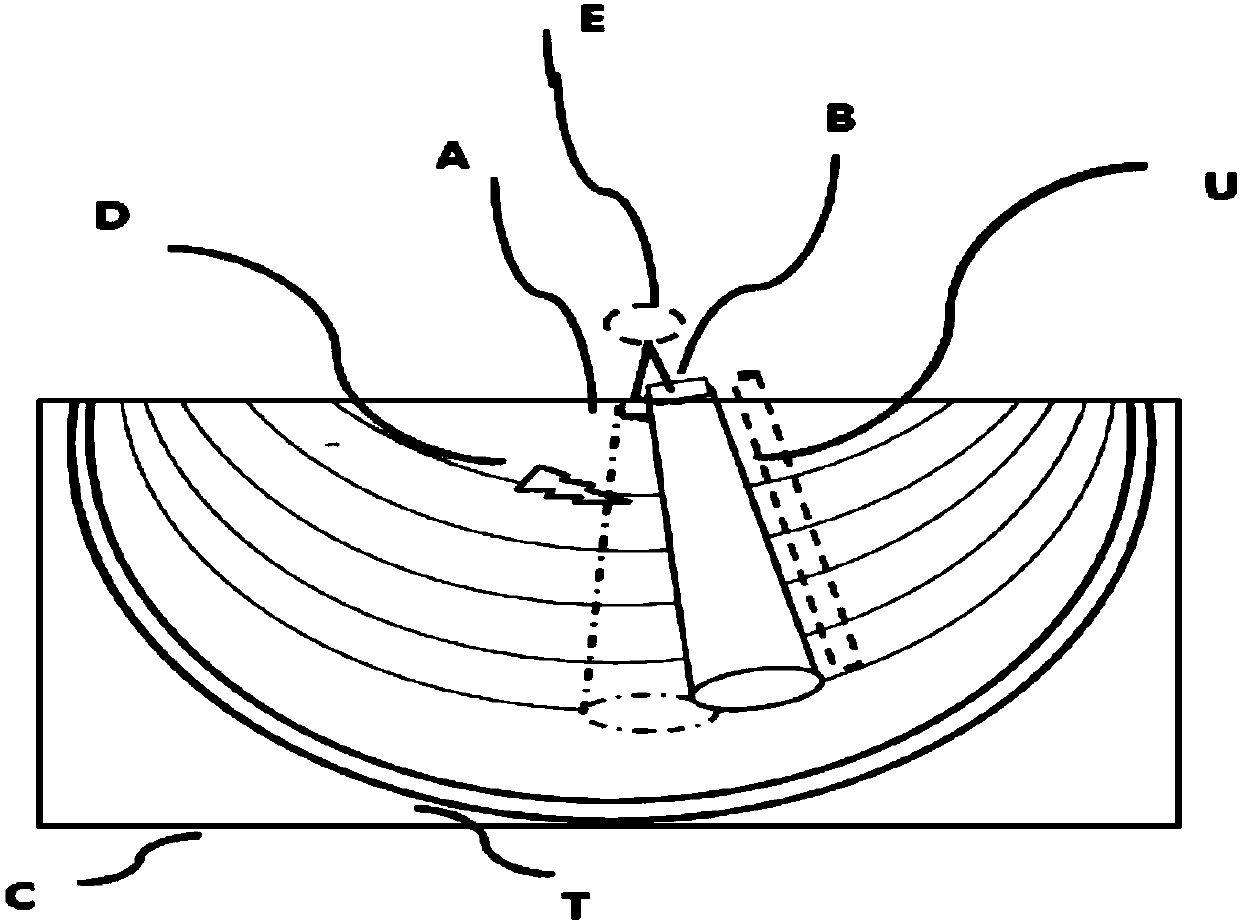

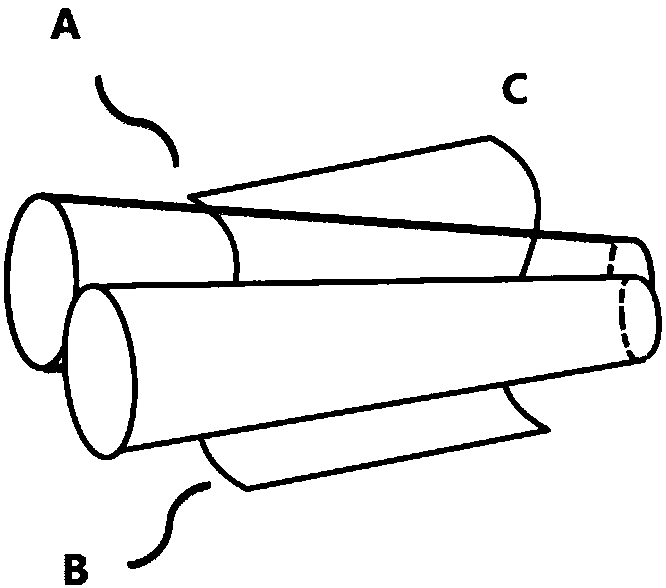

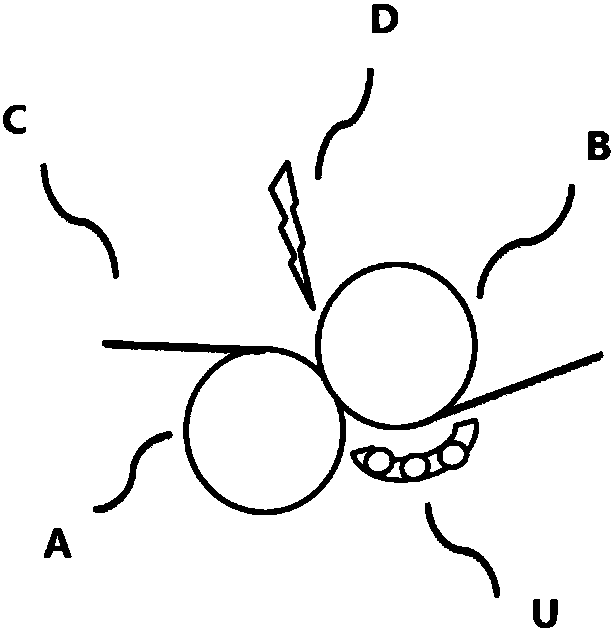

[0037] First: fix the base material C on the base material holder T; in order to ensure the effective demoulding time, the base material C is inserted into the gap between the mirror roll A and the structure roll B from above the mirror roll A, and from the bottom of the structure roll B and The upper part of the curing mechanism U passes through, and the mold passing path is in an "S" shape. Then: open the glue injection mechanism D and inject glue at the large radius of the construction roller B, and open the curing device U. Immediately afterwards: the substrate holder T performs a circular motion with its center as the center point according to the circular direction, and at the same time drives the substrate C to move between the mirror roller A and the structure roller B. Finally: The glue injected by the glue injection mechanism D passes through the structural gap between the mirror roller A and the structural roller B to form a structure consistent with the annular gro...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, the only difference is that in Embodiment 1, the substrate holder T is moving, but the tapered roller assembly is stationary; in Embodiment 2, the mirror roller A and The structure roll B is centered on its own axis, while rotating in the horizontal plane, it revolves around a fixed center in the horizontal plane. The substrate clamp T remains fixed, so that the substrate C moves relative to the mirror roll A and the structure roll B. In the above process, the glue injected by the glue injection mechanism D passes through the structural gap between the mirror roller A and the structural roller B to form a structure consistent with the annular groove superimposed on the surface of the structural roller shaft, and then reaches the curing area of the curing device U. Instant curing is completed to obtain the formed structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com