Lens processing equipment and processing method thereof

A technology of processing equipment and processing methods, which can be applied to other household appliances, household appliances, optical components, etc., can solve the problem of inability to guarantee the uniformity of 4V light-cured adhesive application, the lack of thickness uniformity, and the inapplicability of large-scale continuous Production and other issues, to achieve the effect of ensuring the amount of glue, reducing loss, and reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

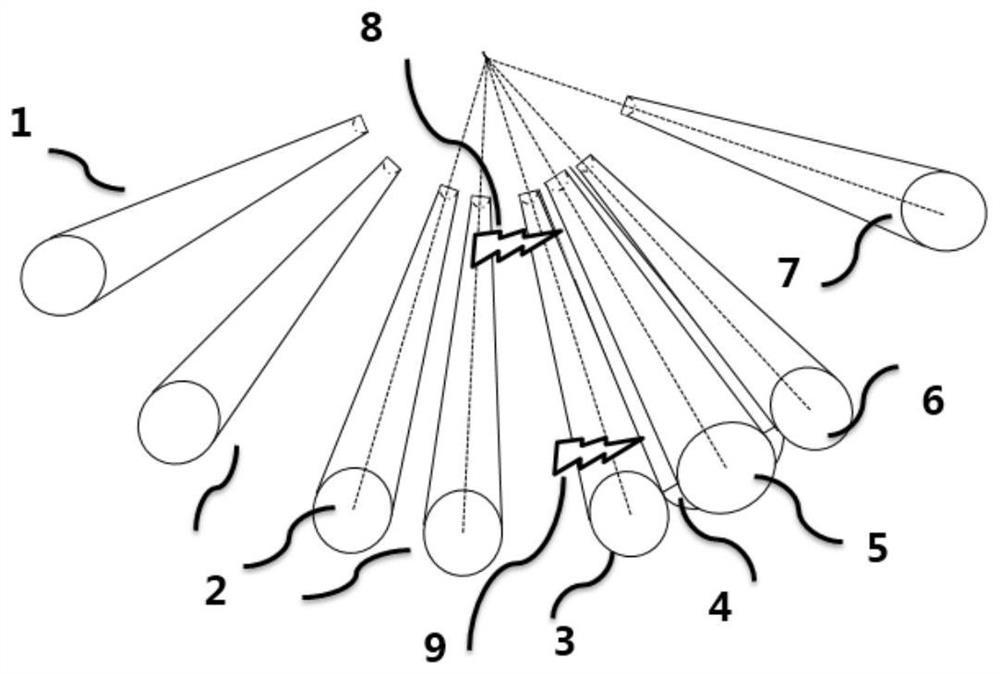

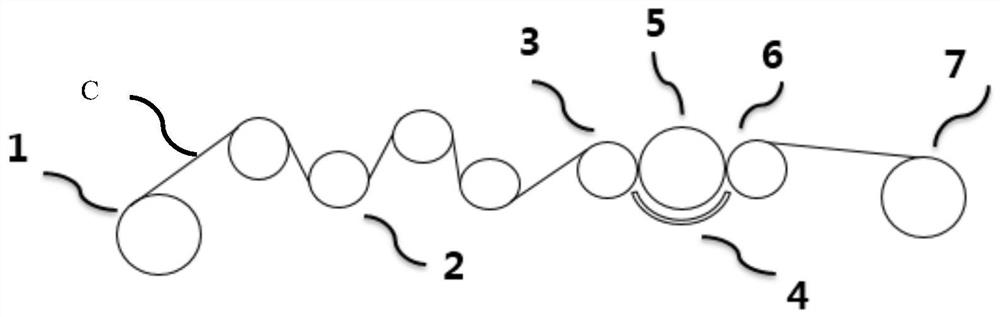

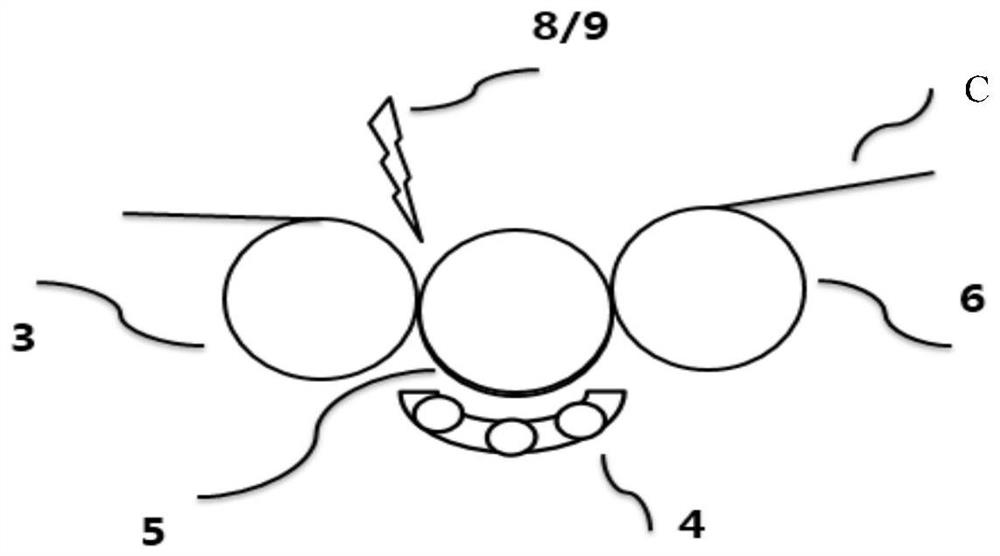

[0039] figure 1 It is a three-dimensional schematic diagram of the overall structure of the production equipment of the present invention; figure 2 It is a schematic plan view of the overall structure of the production equipment of the present invention; image 3 It is a schematic diagram of the local installation positions of the mirror roller, the structure roller and the curing mechanism of the present invention. like Figure 1 to Figure 3 As shown, the present invention provides a lens processing equipment. The production equipment mainly includes a conical roller linkage assembly. 2. The mirror roller 3, the structure roller 5 and the receiving roller 7, each tapered roller in the said tapered roller linkage assembly can perform a circular motion around its connecting end as the center. The surface of the mirror roller 3 is electroplated with a hard metal coating, and the surface of the structural roller 5 is provided with an annular groove structure. The production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com