Printing method and product thereof

A printing method and ink layer technology, applied in the printing field, can solve the problems of difficult to control the consistency of incoming materials, increased height difference, and large fluctuation of paste quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

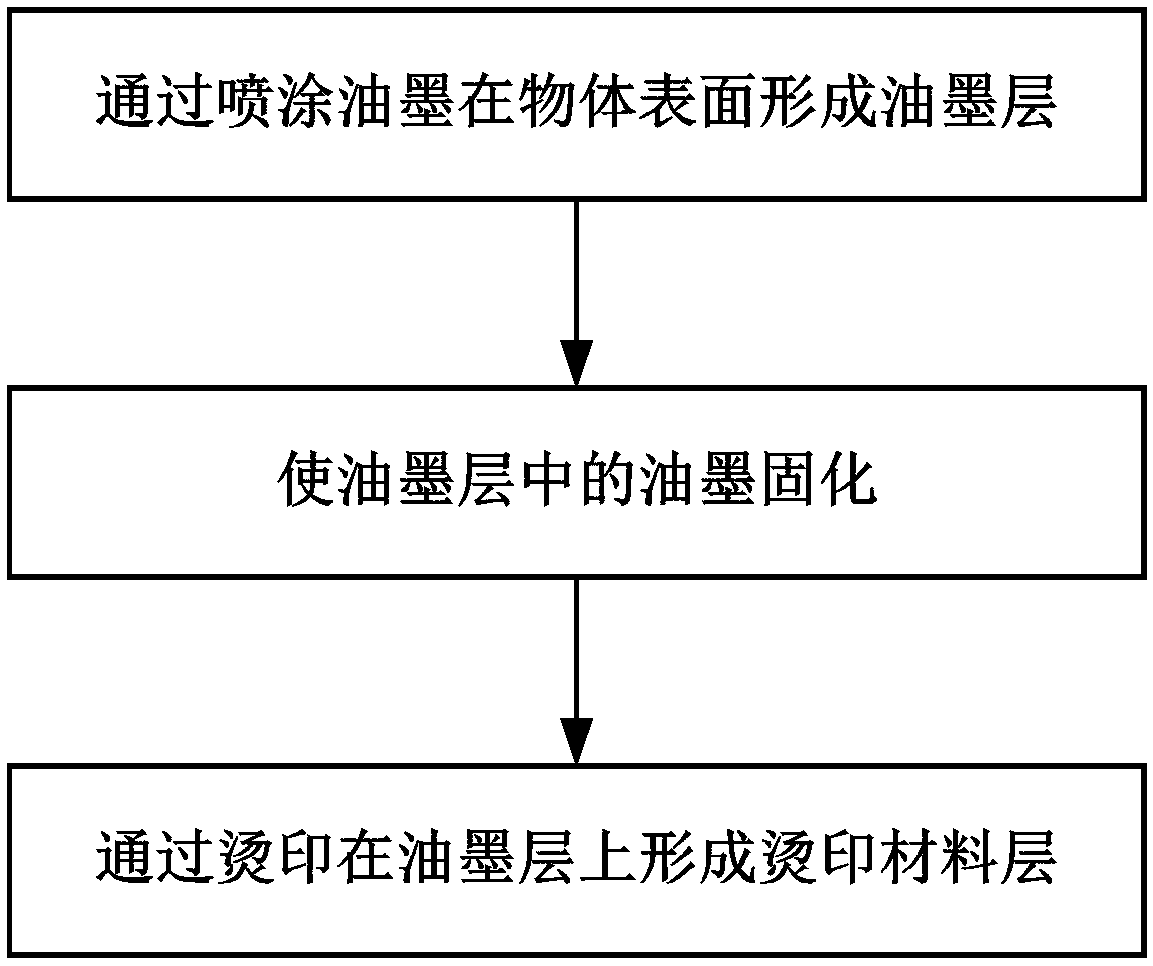

Method used

Image

Examples

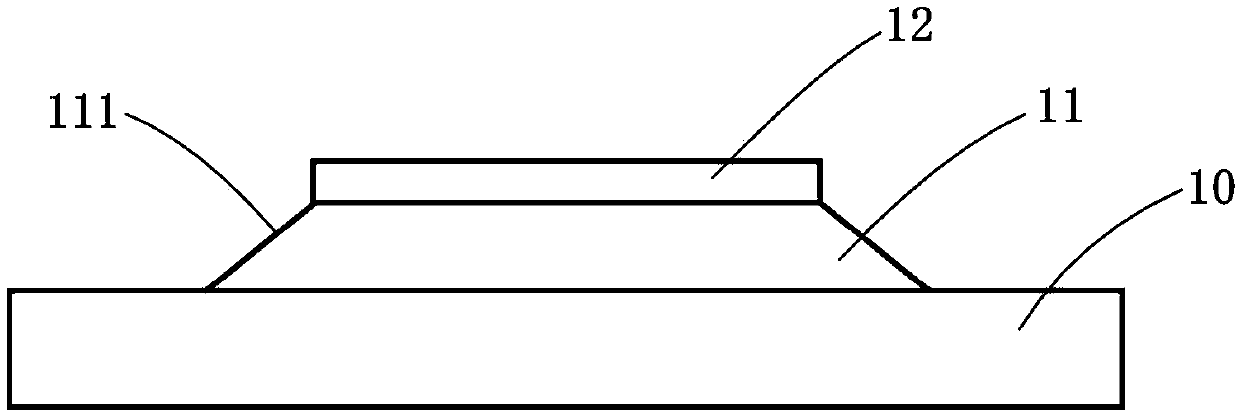

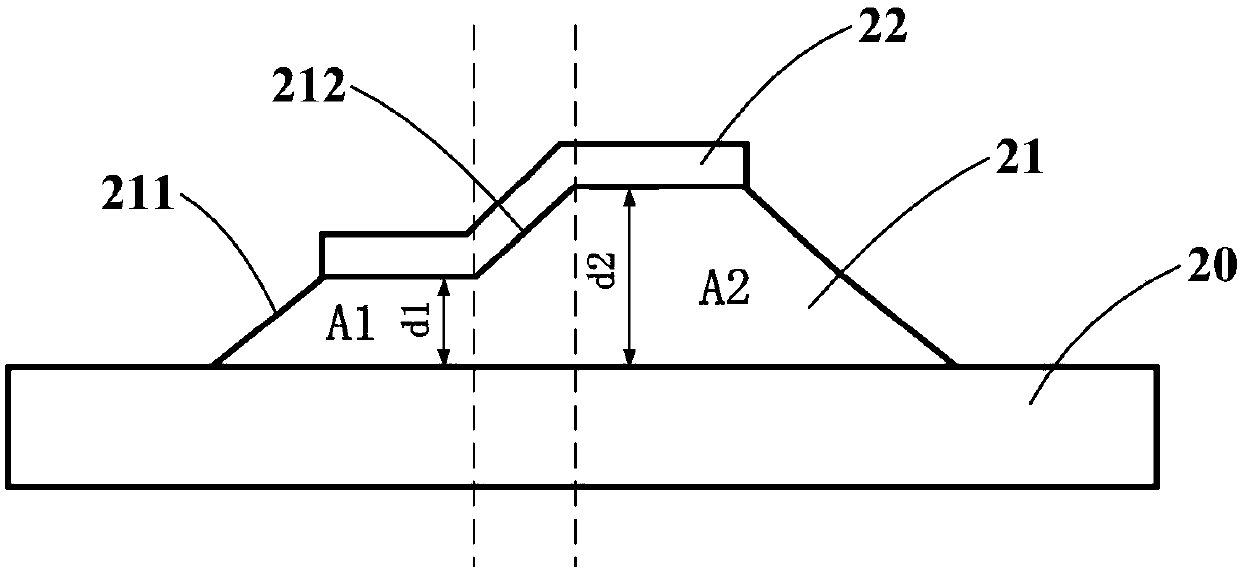

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present application easier to understand, the technical solution of the present application will be further described in detail below in conjunction with the accompanying drawings and exemplary embodiments. It should be noted that the application is not limited to the construction or details presented below or illustrated in the drawings. The present application may also have other embodiments or be implemented in other ways.

[0020] It should be understood that the words "comprising", "comprising", and "having" used in this specification do not exclude other elements or steps, and the directional terms used herein, such as "left", "right", "on", " "below" and so on are only used to indicate the orientation or orientation of corresponding features in the drawings for the convenience of description and understanding, and should not be construed as limiting the structure of the present application. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap