Double-end-sealing reciprocating high-speed pillow-type packing machine

A pillow charter, duplex technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of negative impact of film release and transportation, weak packaging and sealing, short heat sealing time, etc., to achieve good packaging effect and simple structure. , the sealing effect is firm and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

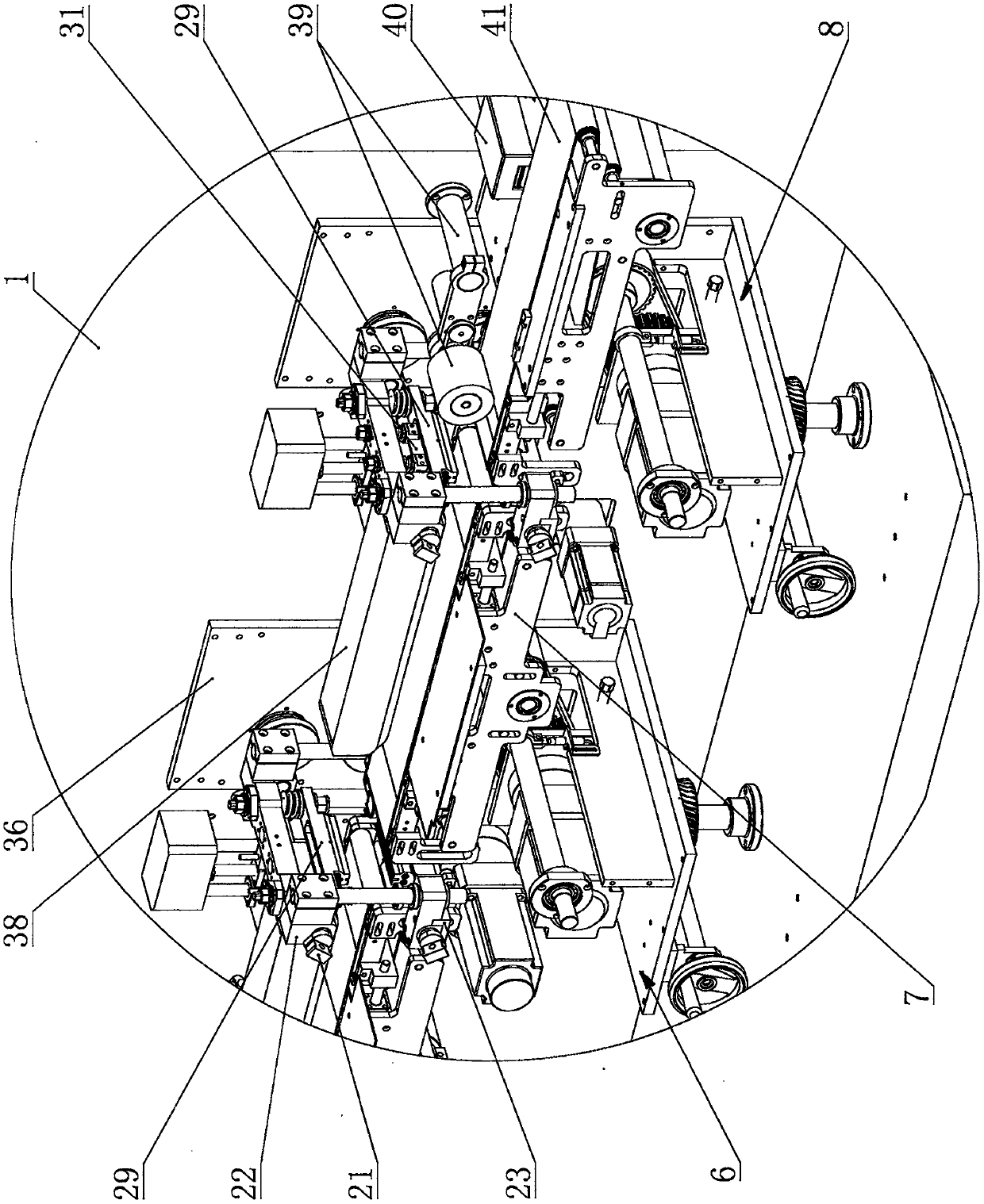

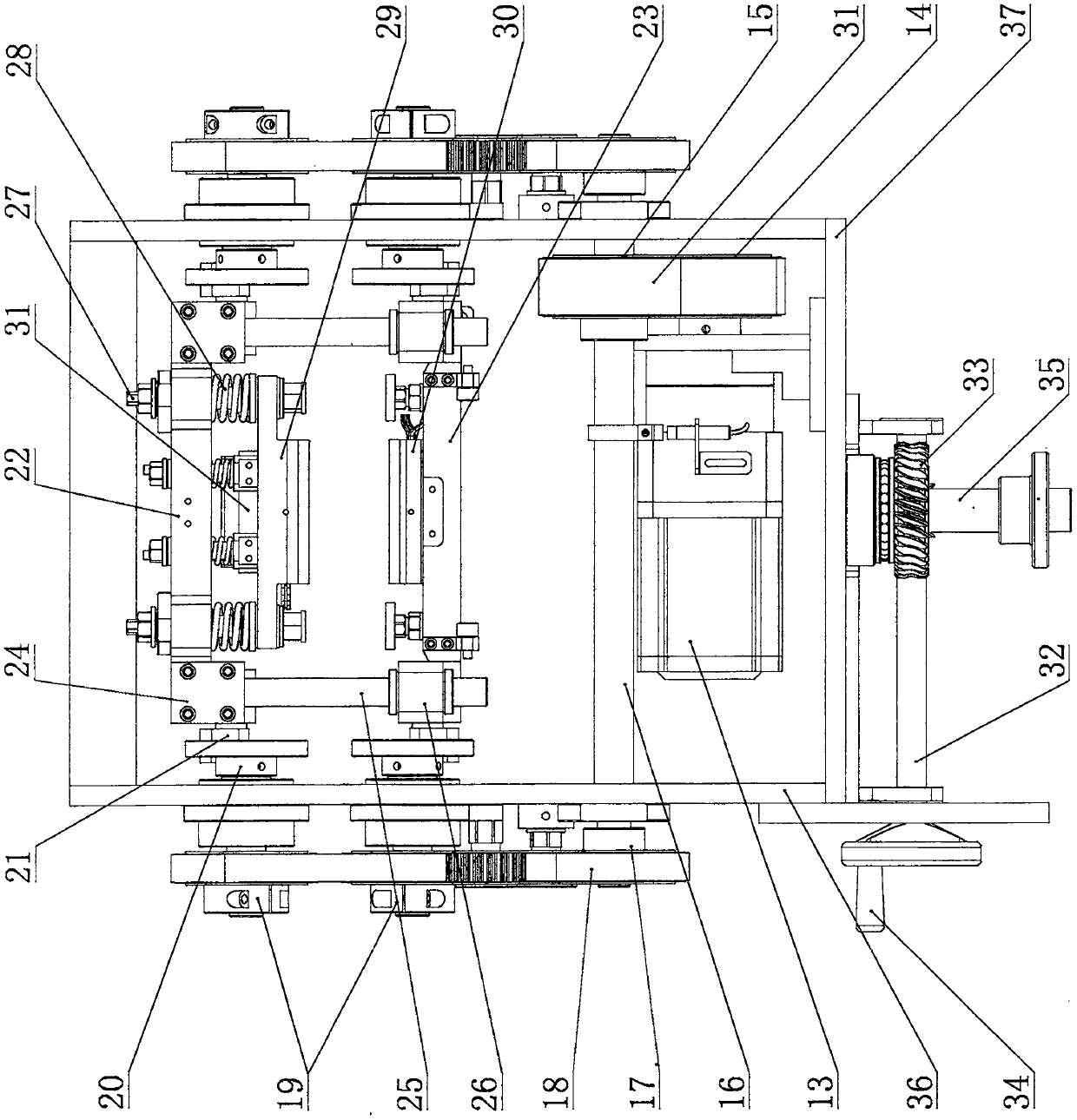

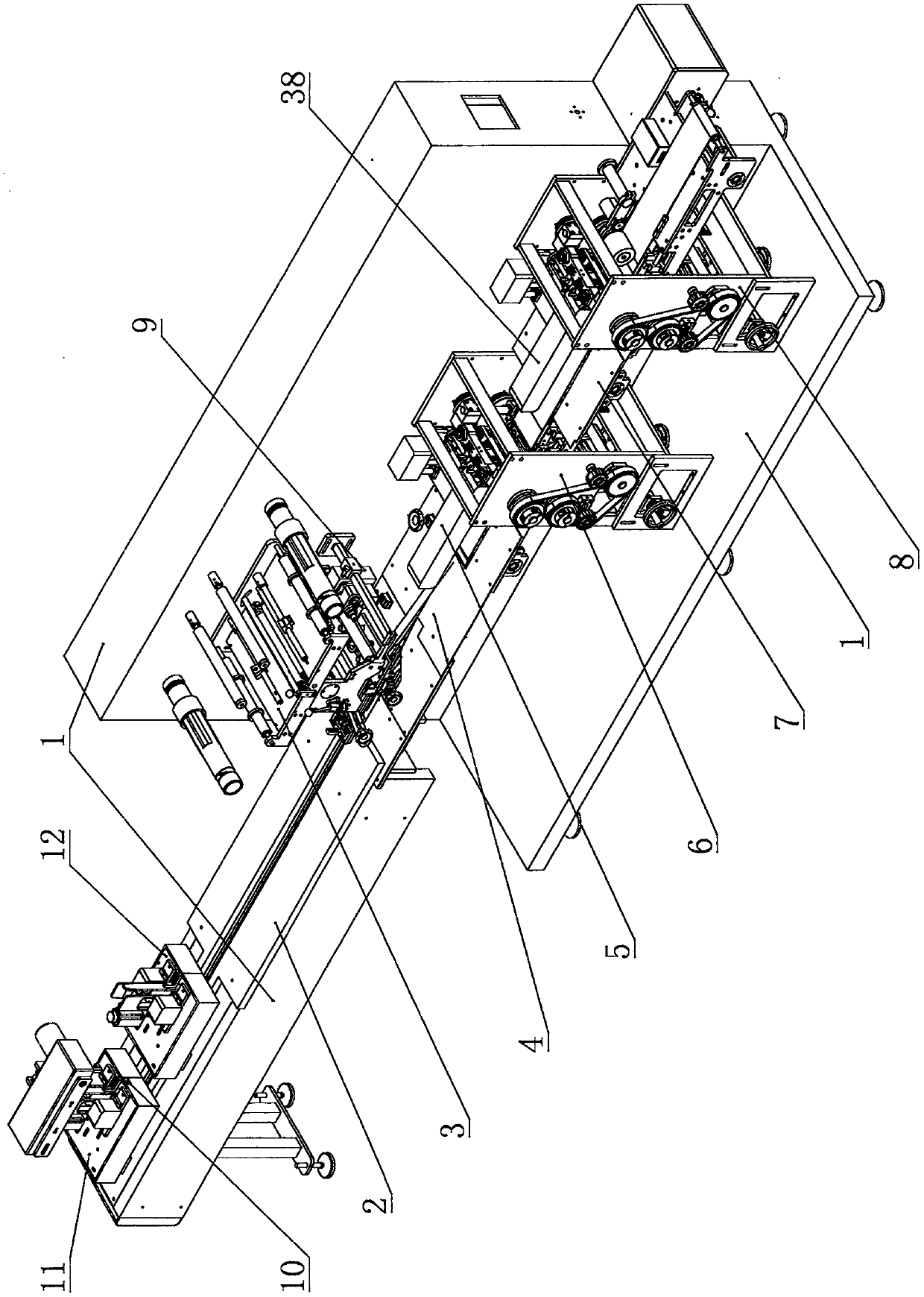

[0011] Reference Figure 1 to Figure 3 It can be seen that the double-end sealing reciprocating high-speed pillow wrapping machine of the present invention includes a frame 1, a material feeding device, a material conveying device 2, a film releasing device 3, a material packaging and conveying device 4, and a second heat sealing and cutting device 8. The material adding device It is composed of one feeding assembly 11 and two feeding assemblies 12 in sequence (that is, a double feeding method), and a feeding detection assembly 10 is installed on the frame 1 and between the one feeding assembly 11 and the second feeding assembly 12 (Photoelectric type); On the frame 1, and at the side of the two heat sealing and cutting devices 8 (previous process), a preheating sealing device 6 is installed, on the frame 1, and in A transition conveying device 7 is installed between a preheating sealing device 6 and the second heat sealing and cutting device 8. The entrance of the preheating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com