Metal bipolar plate used for proton exchange film fuel cell and preparative method

A technology of metal bipolar plates and proton exchange membranes, which is applied to fuel cell parts, battery electrodes, circuits, etc., can solve the problems of complex manufacturing process and high processing costs, and achieve strong and reliable sealing, reliable bonding, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of thin metal bipolar plates without wire seals:

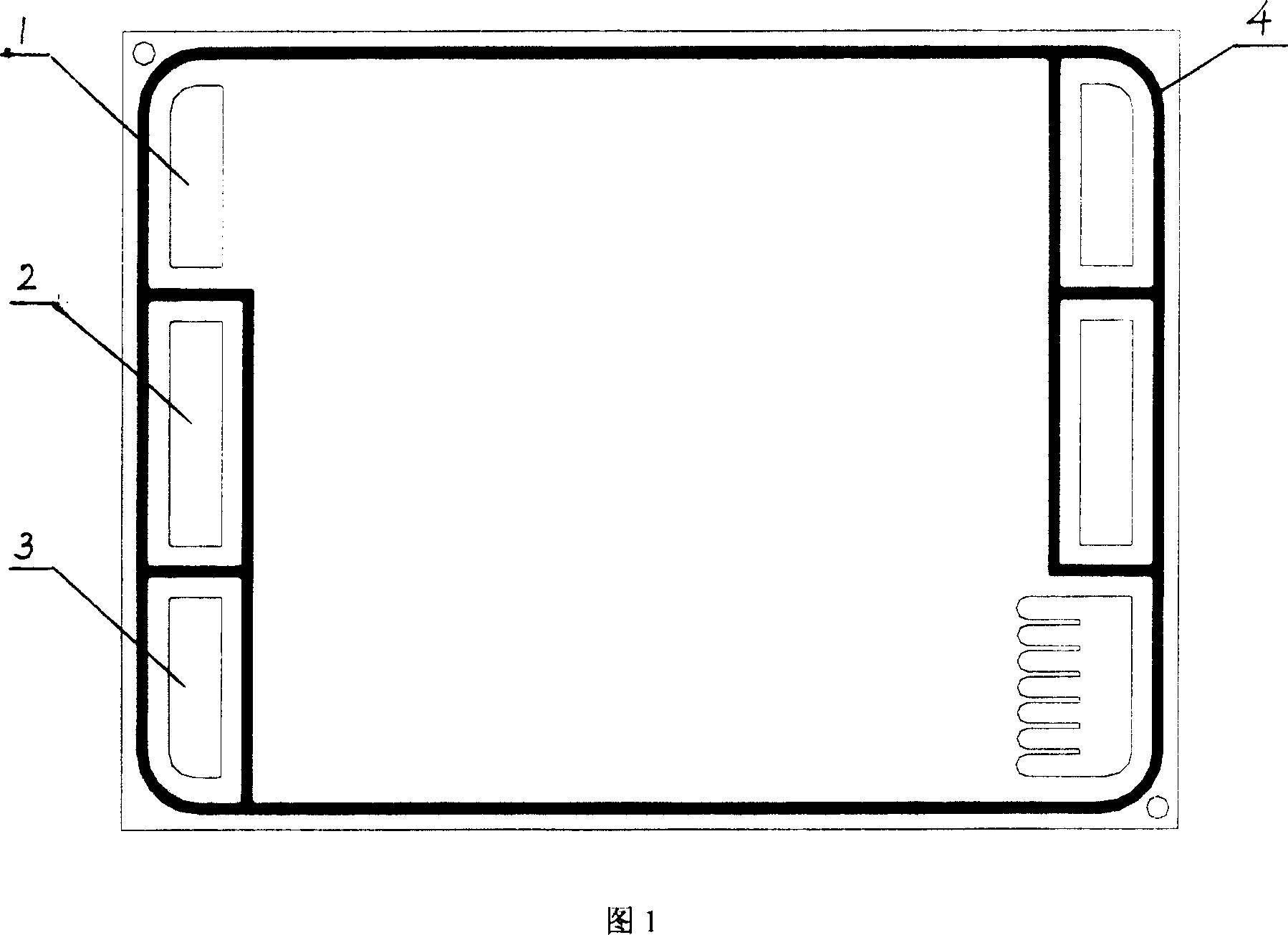

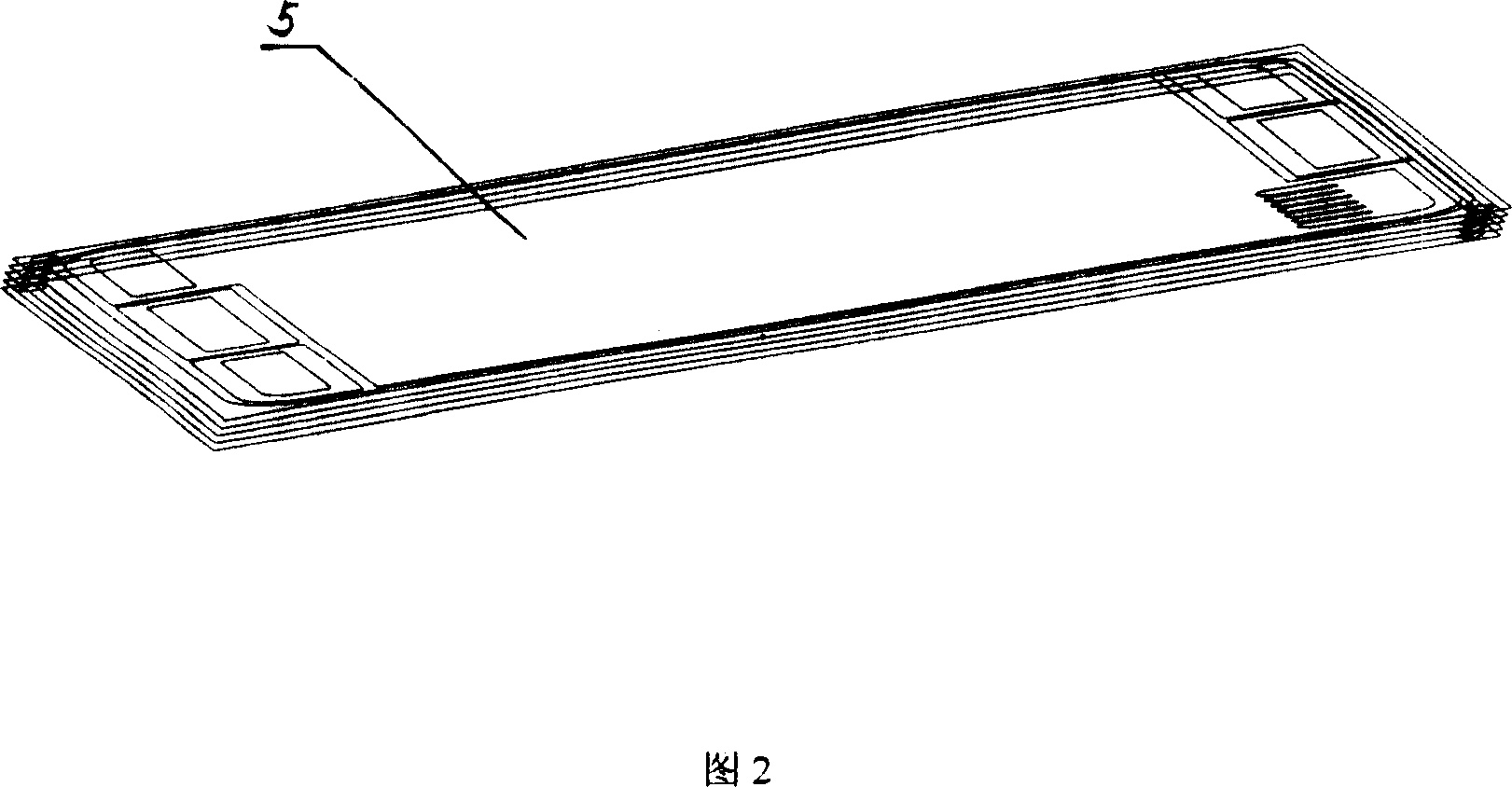

[0046] Select the working area as 130cm 2 Five sheets of stainless steel fuel cell machined plates with a thickness of 0.4mm, around the working area and around the gas and liquid chambers, anyway, use 85% by weight phosphoric acid (analytical pure) as an adhesive on both sides, and spread evenly on the bipolar plates Around the working area and around the gas and liquid chambers, strips or wires made of tin-silver, tin-copper, tin-bismuth and other materials are evenly bonded around the bipolar plate as a sealing line, and the single machined plate is coated and sealed. See Figure 1 after the line, and after positioning the five boards, stack them up one by one, and take them to the vulcanizing machine for high-temperature and high-pressure treatment (temperature is 180°C, pressure is 0.08MPa). Before the preparation, the upper and lower end plates of the vulcanizing machine must be processed flat and smoo...

Embodiment 2

[0048] Preparation of thin metal bipolar plates with platinum wire seals:

[0049] Select the working area as 120cm 2 Five sheets of stainless steel fuel cell machined plates with a thickness of 0.4mm, around the working area and around the gas and liquid chambers, anyway, use 90% by weight phosphoric acid (analytical pure) as an adhesive on both sides, and evenly spread on the bipolar plates Around the working area and around the gas and liquid chambers, strips or wires made of tin-silver, tin-copper, tin-bismuth and other materials are evenly bonded around the bipolar plate as a sealing line, and a smooth platinum wire Spot welding on the sealing line, and then after positioning the five plates, stack them up one by one, and take them to the vulcanizing machine for high temperature and high pressure treatment (temperature is 190°C, pressure is 0.06MPa). Before the preparation, the upper and lower end plates of the vulcanizing machine must be processed flat and smooth to ens...

Embodiment 3

[0051] Preparation of thin metal bipolar plates with platinum wire seals:

[0052] Select the working area as 130cm 2 Five sheets of stainless steel fuel cell machined plates with a thickness of 0.3mm, around the working area and around the gas and liquid chambers, anyway, use 95% by weight phosphoric acid (analytical pure) as an adhesive on both sides, and evenly spread on the bipolar plates Around the working area and around the gas and liquid chambers, strips or wires made of tin-silver, tin-copper, tin-bismuth and other materials are evenly bonded around the bipolar plate as a sealing line, and a smooth platinum wire Spot welding on the sealing line, then after positioning the five plates, stack them up one by one, and take them to the vulcanizing machine for high temperature and high pressure treatment (temperature is 210°C, pressure is 0.09MPa). Before the preparation, the upper and lower end plates of the vulcanizing machine must be processed flat and smooth to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com