Two-way hot sealing and cutting mechanism

A cutting mechanism, heat sealing and cutting technology, applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of negative impact of film release and transportation, weak packaging sealing, short heat sealing time, etc., to achieve packaging effect Good, simple structure, firm and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

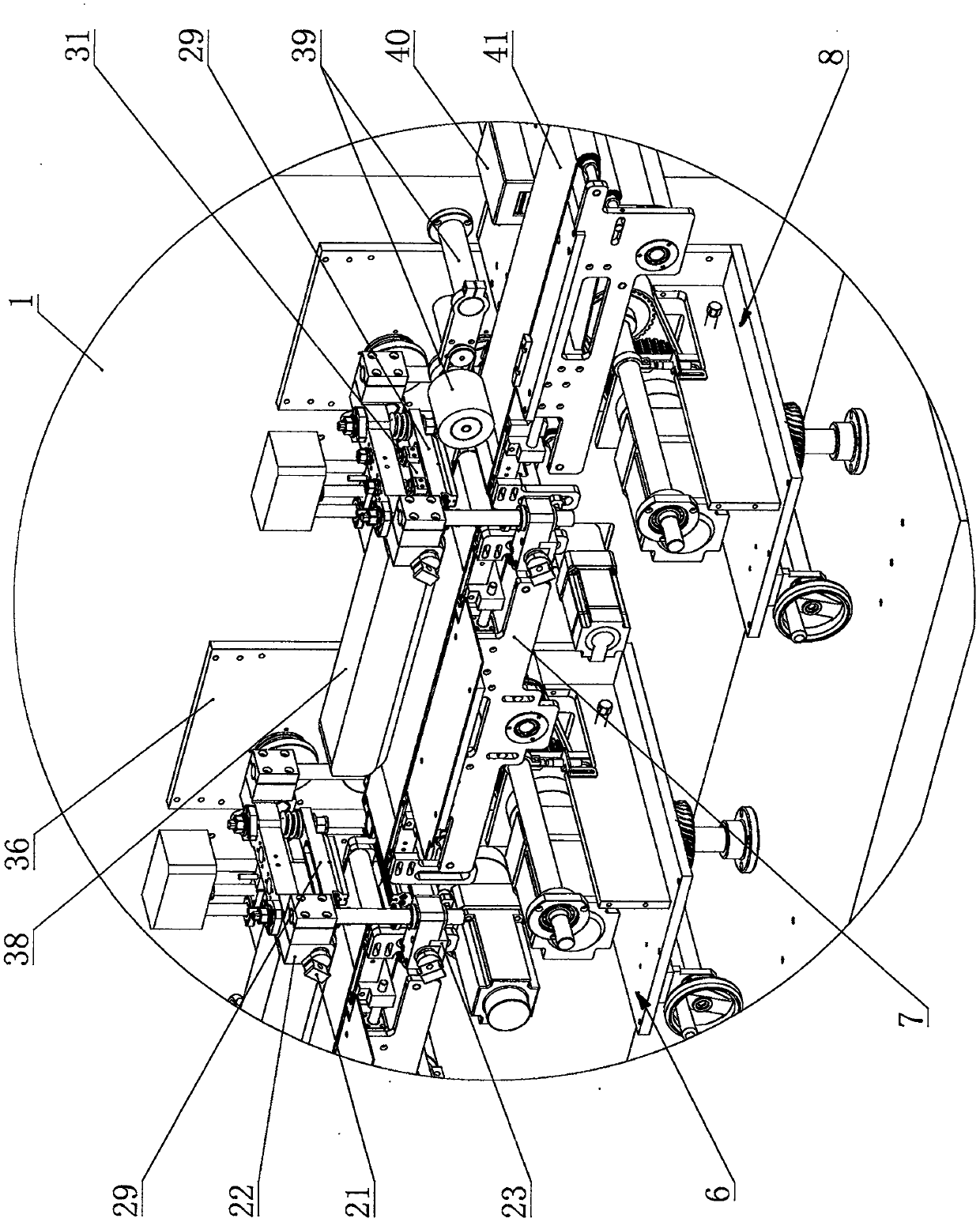

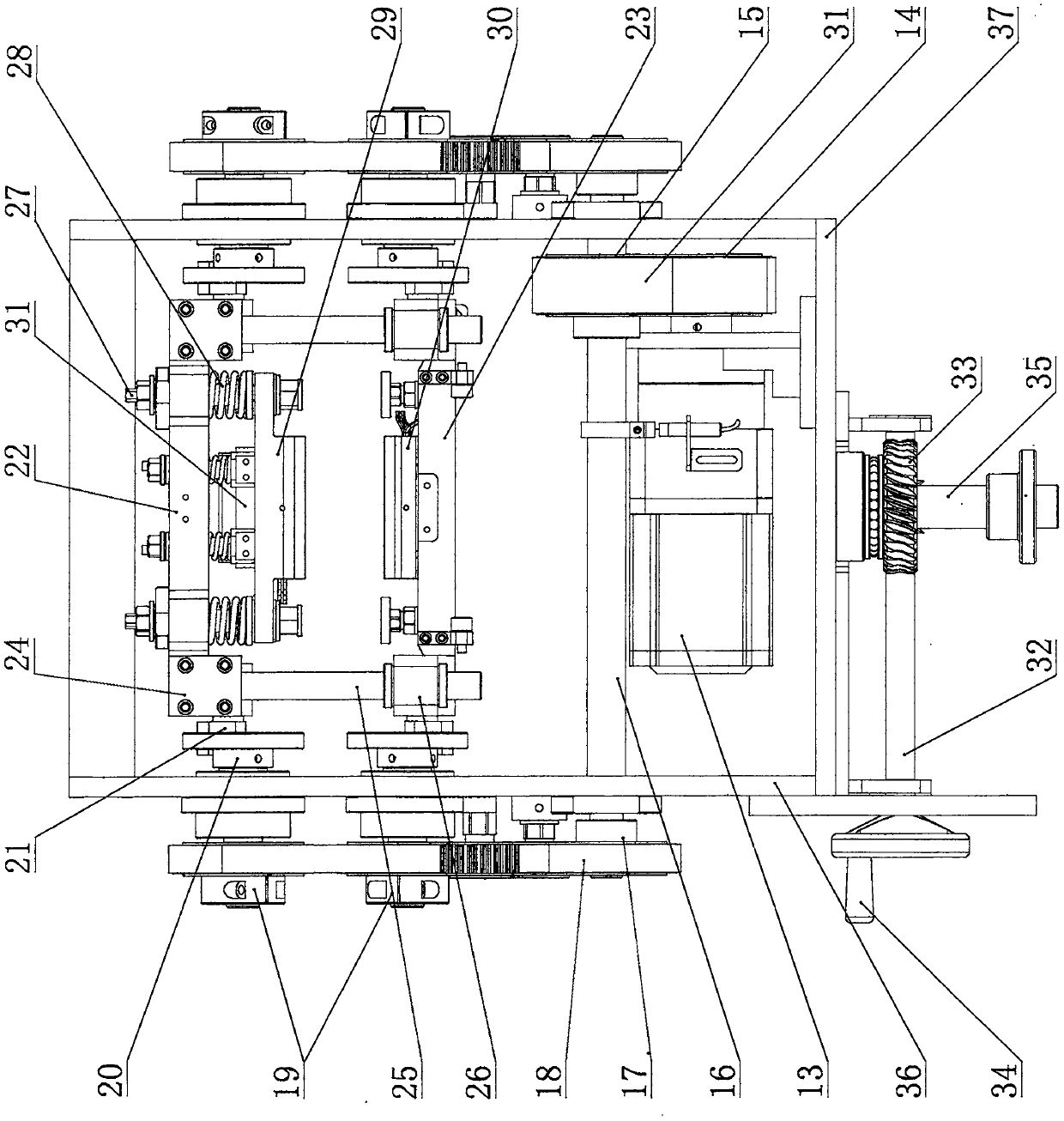

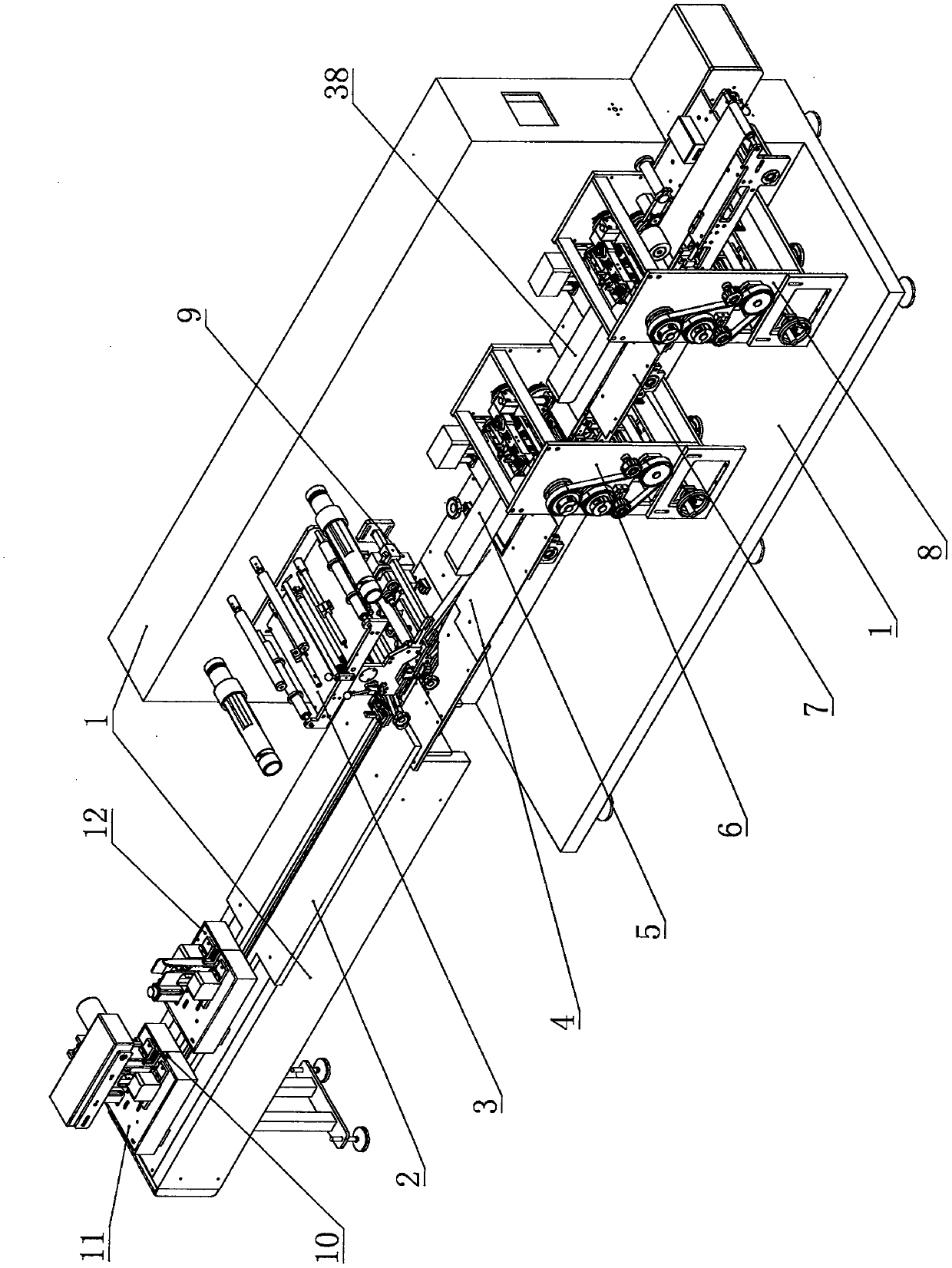

[0012] refer to figure 1 , figure 2 It can be seen that the present invention is applied to the double-channel heat-sealing and cutting mechanism of the pillow bag machine, including a frame 1 and a two-channel heat-sealing and cutting device 8, which are installed on the frame 1 and at the side of the two-channel heat-sealing and cutting device 8. There is a preheat-sealing device 6 , and a transition conveying device 7 is installed on the frame 1 and between the first pre-heat-sealing device 6 and the second heat-sealing and cutting device 8 .

[0013] The first preheat sealing device 6 and the second heat sealing and cutting device 8 all include a arch 36, on which an upper cutter shaft 22 and a lower cutter shaft 23 are installed, and an upper sealing knife 29, the The lower cutter shaft 23 is equipped with a lower sealing knife 30, and the upper cutter shaft 22 and the lower cutter shaft 23 are connected to the end sealing main shaft 16 through the eccentric transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com