Telescopic self-crawling sweeper in wind tunnel pipeline

A cleaning machine, telescopic technology, applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of unsafe operation of free pistons, narrow internal space, long length of compression tubes, etc., and achieve large fastening force , Cleaning effect is good, and the effect of elastic and tight conversion is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] The invention provides a telescopic self-crawling cleaning machine in a wind tunnel pipeline, which realizes automatic cleaning of compression tubes in a free-piston shock wave wind tunnel, and can improve the operating efficiency and safety of this type of wind tunnel.

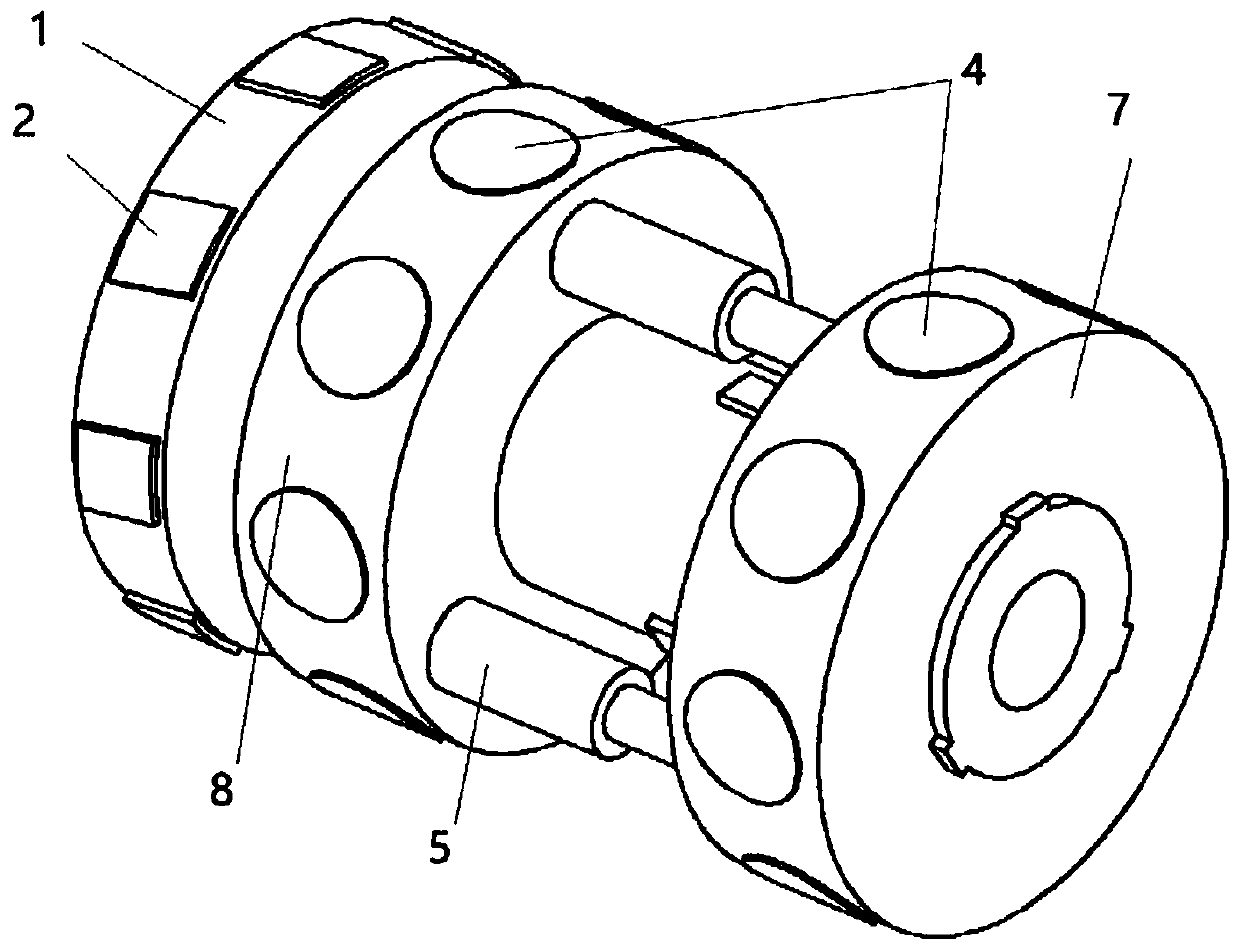

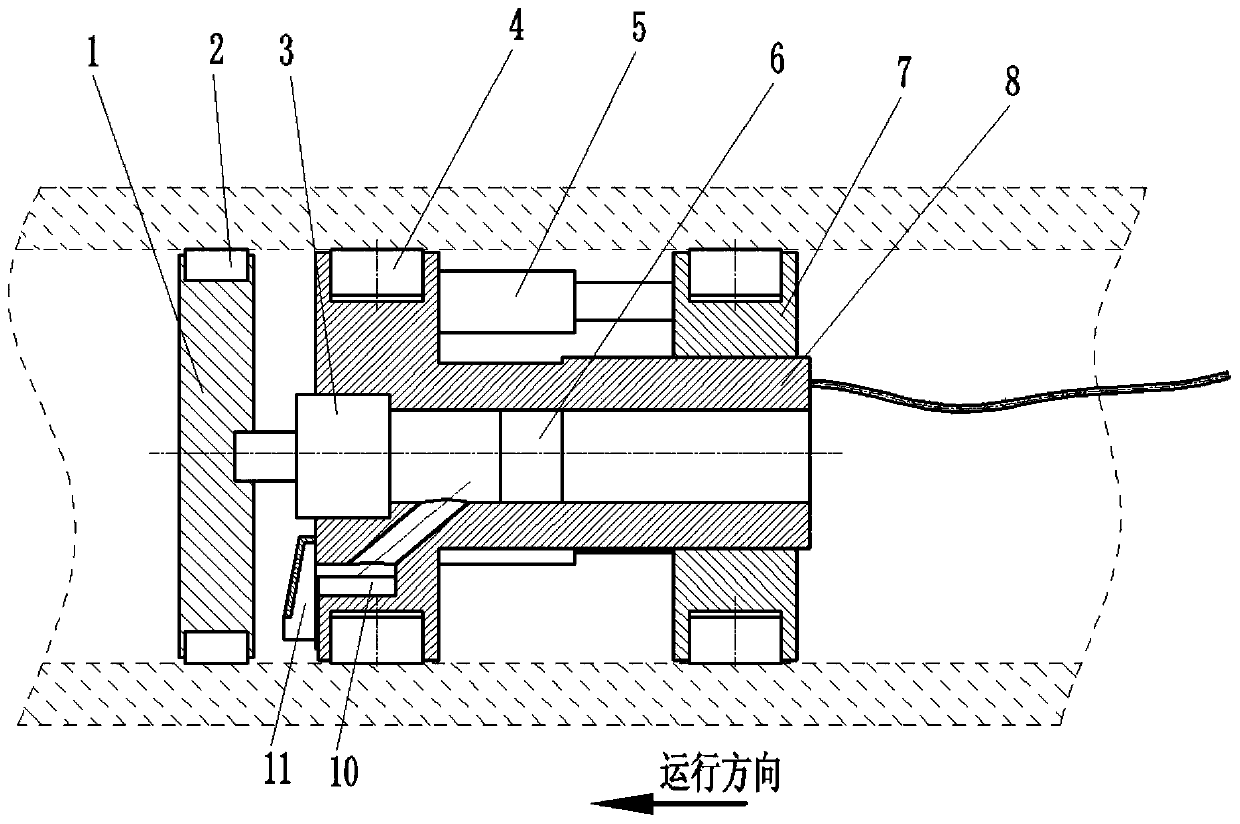

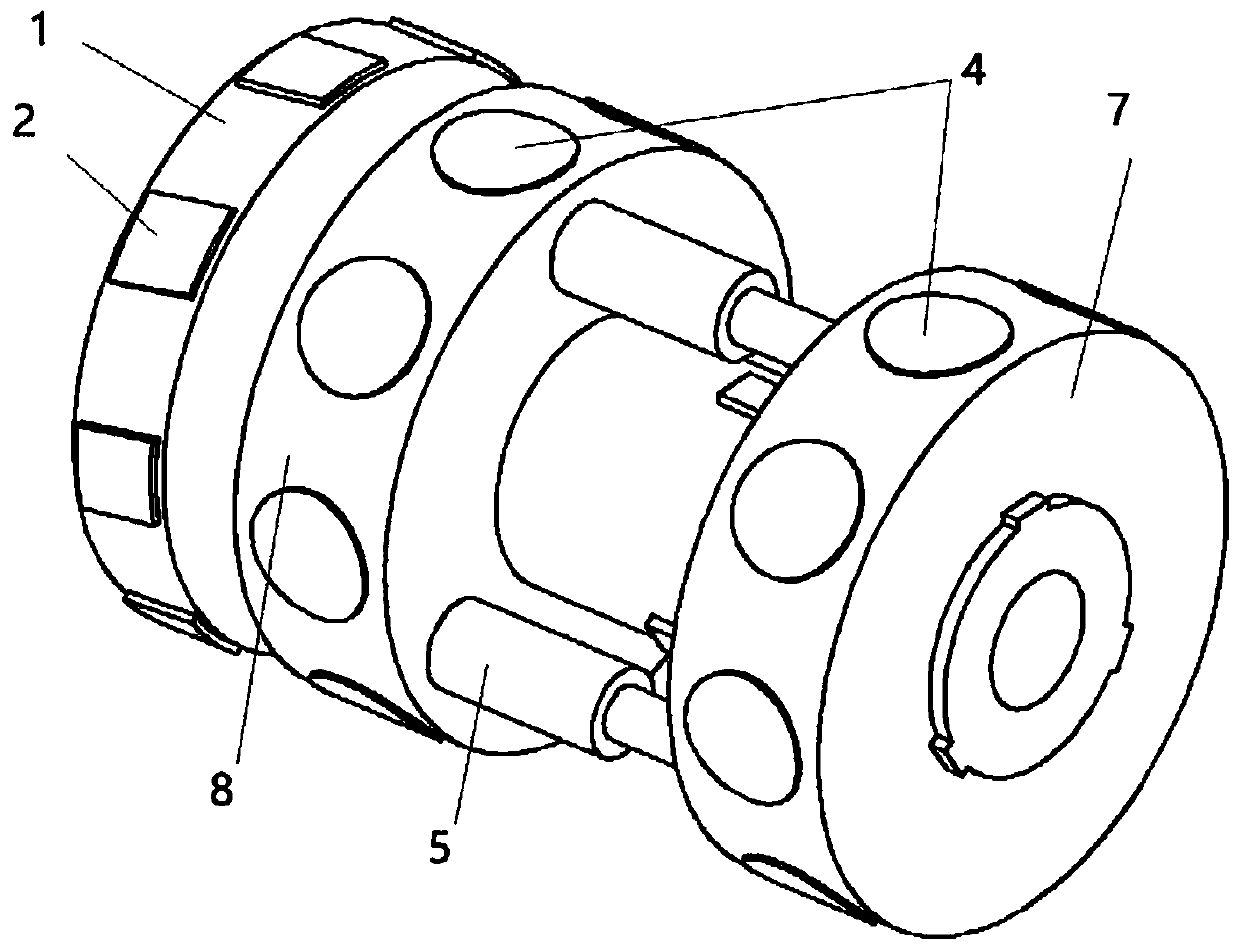

[0025] Such as figure 1 Shown is a schematic diagram of the cleaning machine, such as figure 2 Shown is a sectional view of the cleaning machine. It can be seen from the figure that a telescopic self-crawling cleaning machine in a wind tunnel pipeline includes a cleaning disc 1, n cleaning blocks 2, a motor 3, two sets of electromagnet groups 4, a telescopic mechanism 5, a suction Dust mechanism 6, sliding body 7 and main crawling body 8; wherein, the motor 3 is placed horizontally; the dust suction mechanism 6 is arranged in the middle of the motor 3; the cleaning dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap