Structure member for dry hanging of veneer on wall surface steel joist and application method thereof

A technology for structural components and decorative panels, applied in building construction, covering/lining, construction, etc., can solve the problems of affecting the scope of use, high cost, and large use of angle steel, so as to improve the bearing capacity, reduce the project cost, The effect of saving angle steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

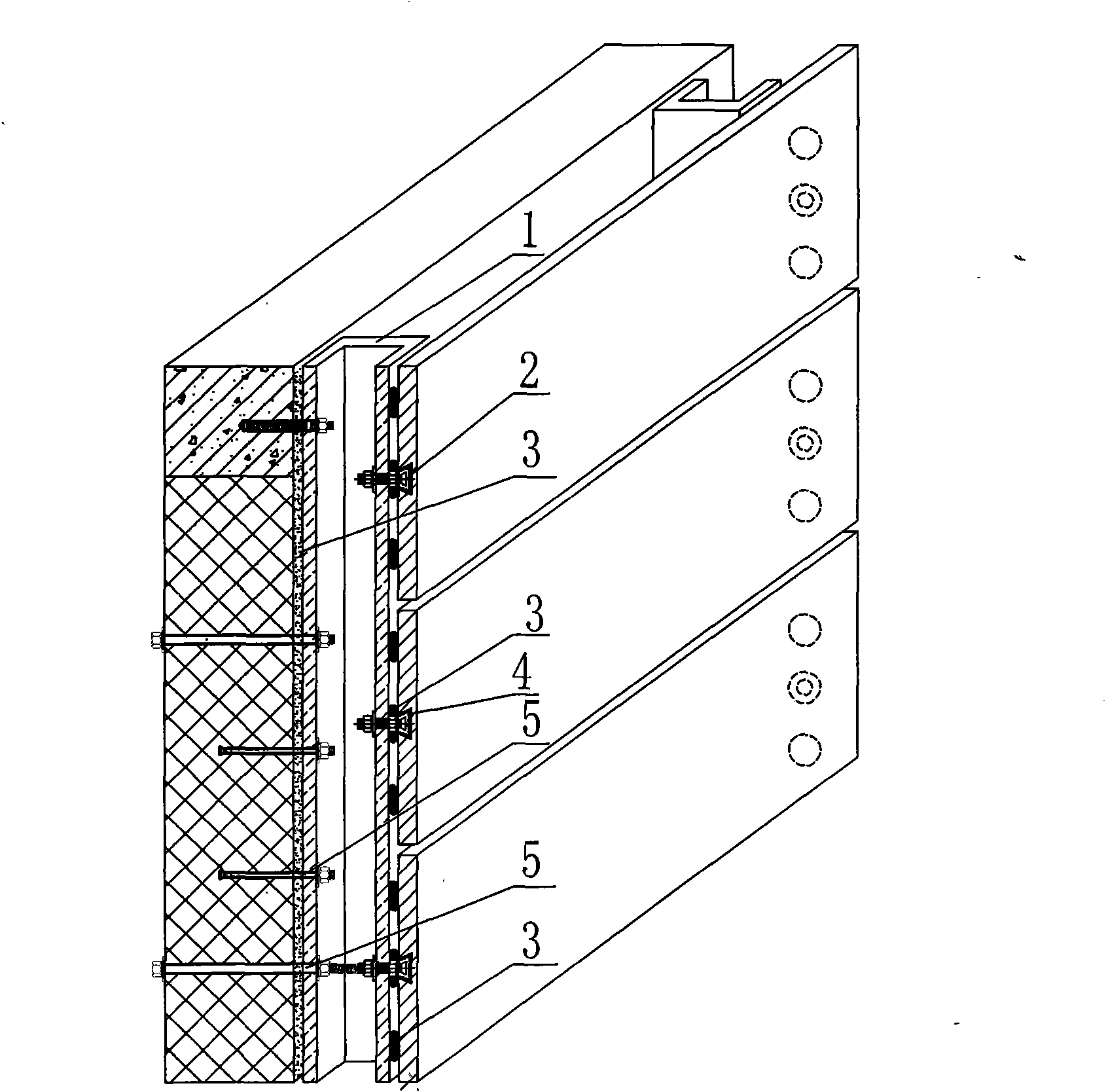

[0009] refer to figure 1 , taking the conventional 3 cm thickness of the veneer as an example, the keel is made of 6# channel steel, and the two ends are fixed on the structural beams and columns of the wall as usual, and an M12 wall-through bolt is used every 2m in the middle. The middle of the wall-through bolts is one meter apart and then fixed to the wall with an M12 expansion bolt, and adhesive glue is also used between the keel and the wall. Although the 6# channel steel is small, the bearing capacity is doubled under the double action of fastening bolts and adhesive, and then the decorative panel is directly fixed on the keel through the countersunk head-shaped pendant and adhesive. Since at least two or more peg hole slots on the veneer are matched with the countersunk head-shaped pendants on the two keels respectively, several glue points are used to stabilize the veneer so that the veneer can be fixed on the keel very firmly.

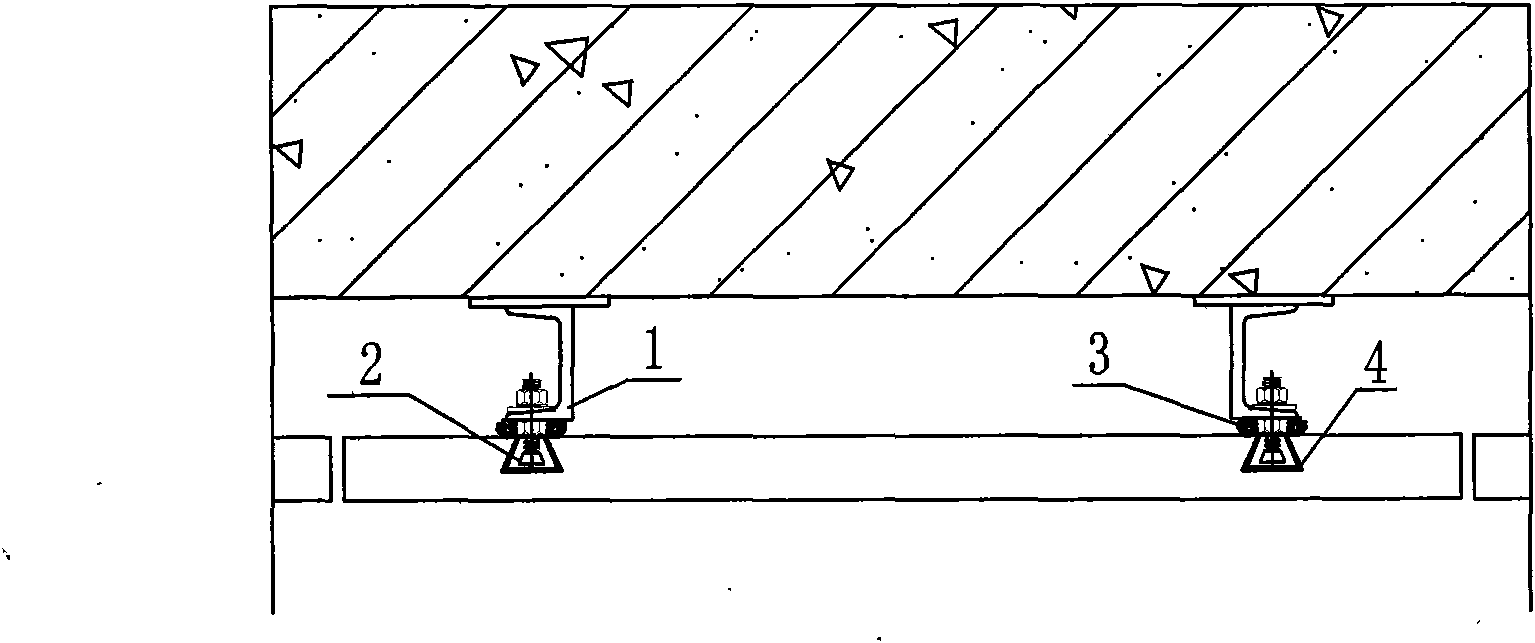

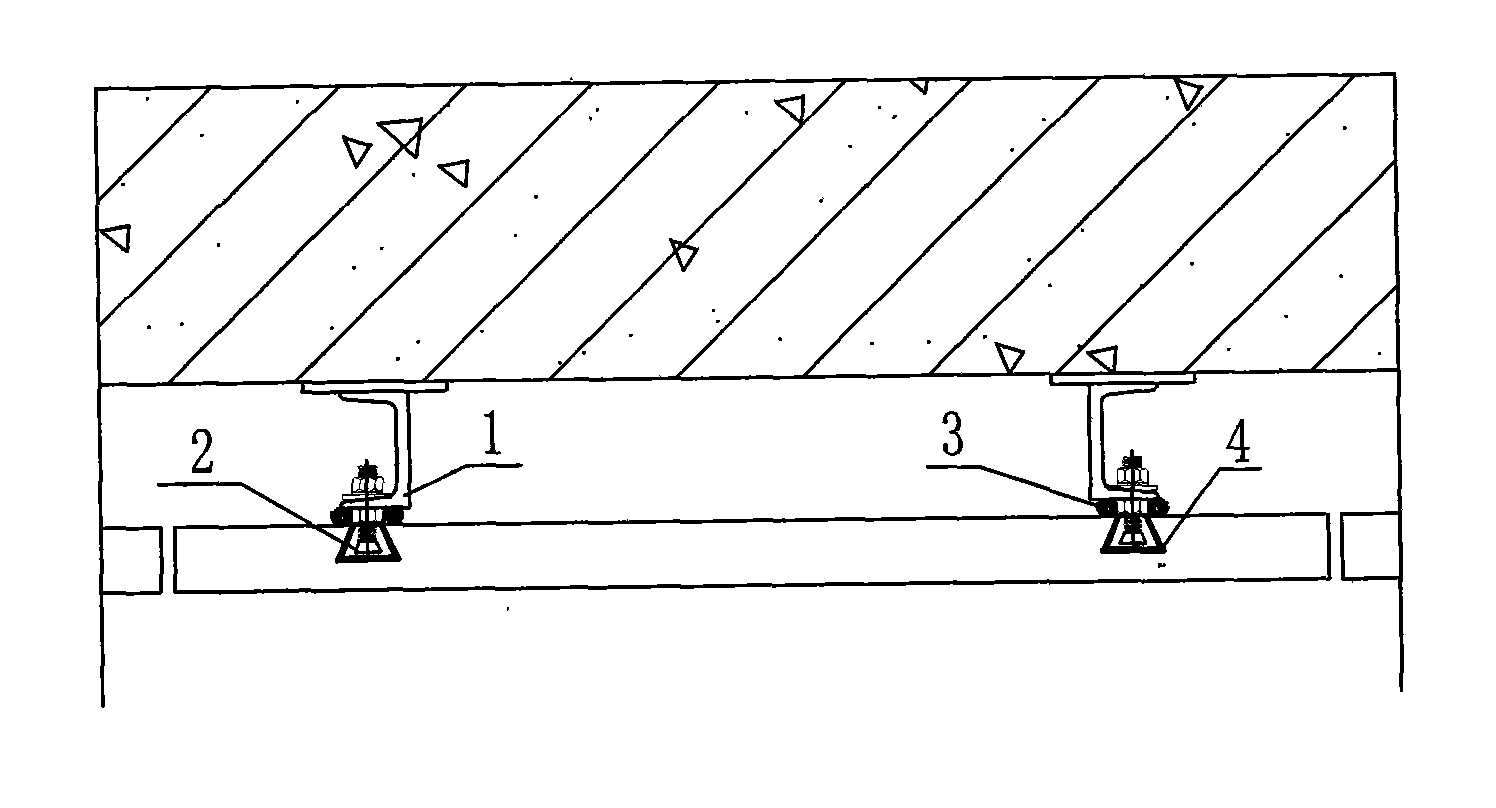

[0010] refer to figure 2 , when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com