Wheel Hub Forming Device and Its Supercharging Mechanism

A technology of wheel hub and hydraulic press, applied in the field of automobile wheel hub forming device and its pressurizing mechanism, can solve the problems of inability to provide large operating space and small mold opening stroke, and achieve the effects of large stroke, increased forming force, and large operating space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

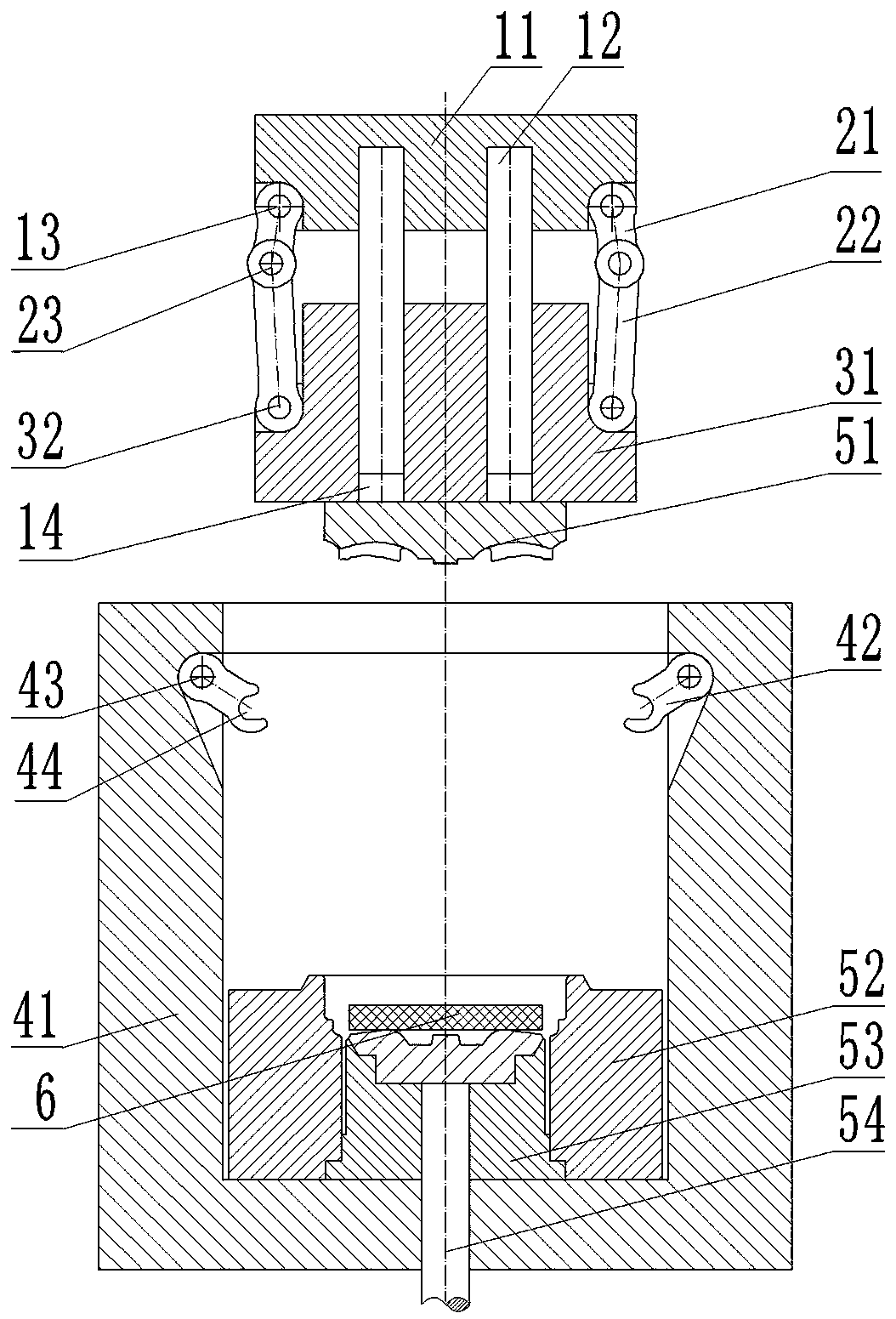

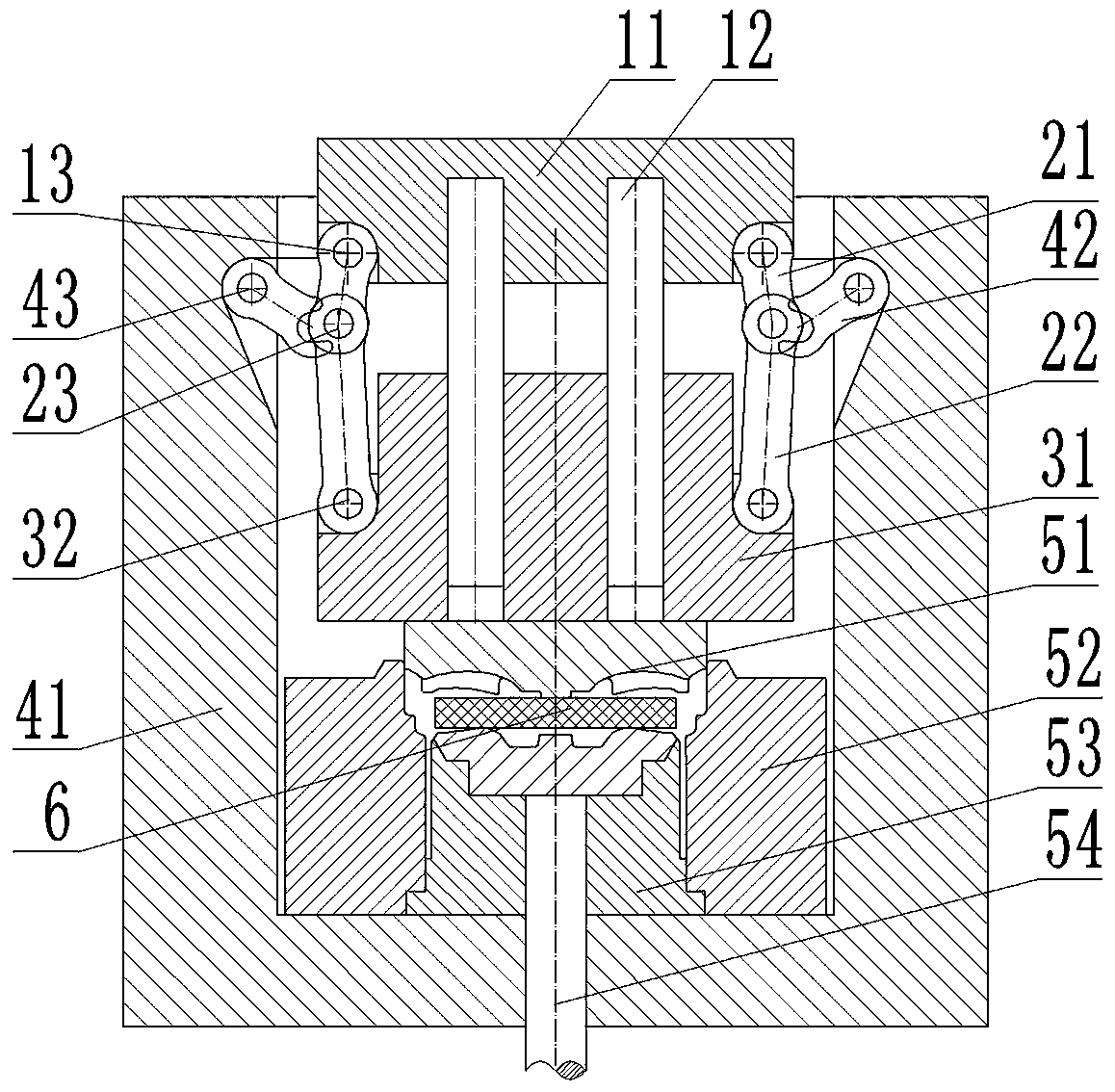

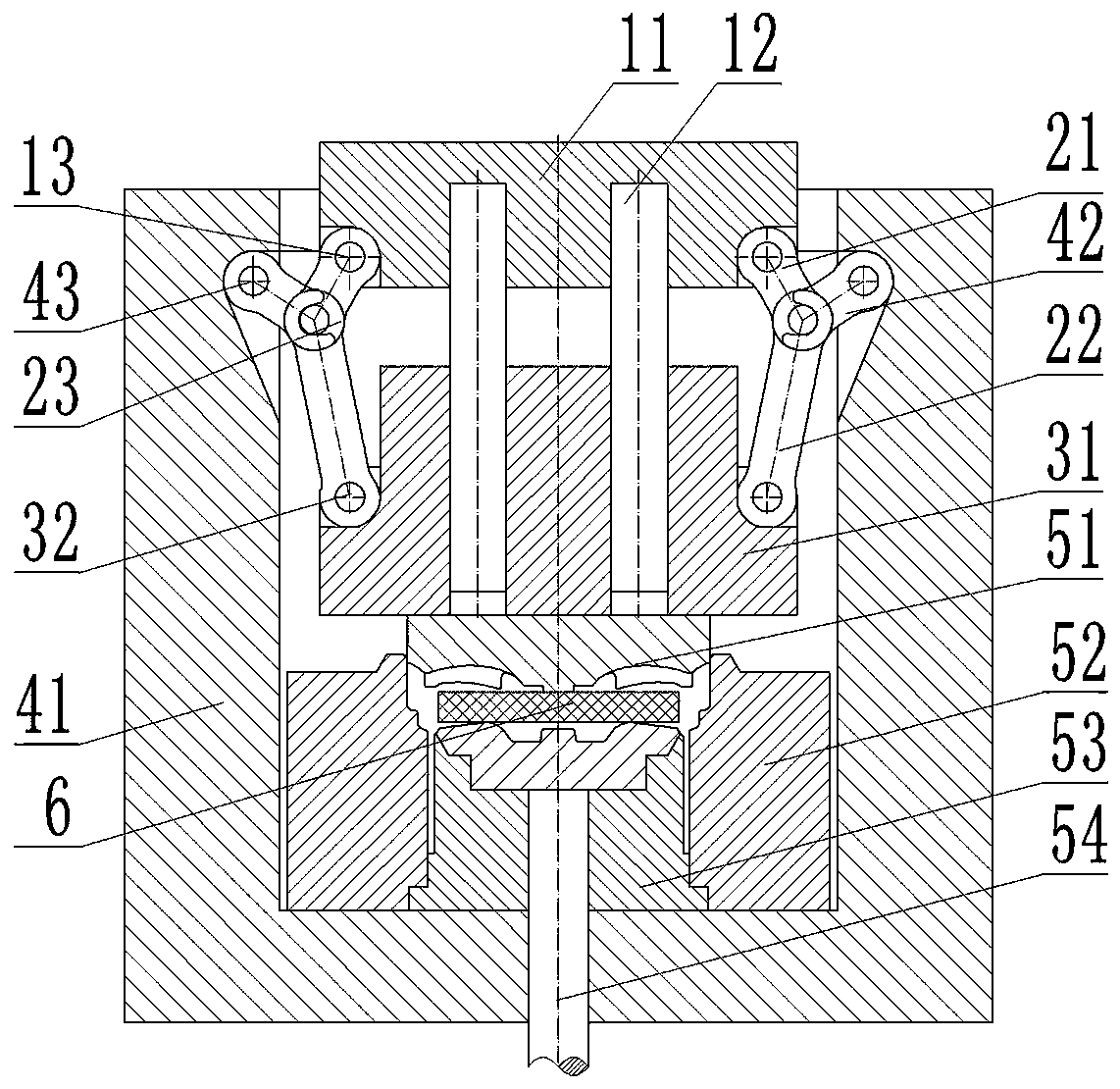

[0028]Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] The specific embodiment of the wheel hub forming supercharging mechanism of the present invention, as Figure 1 to Figure 4 As shown, the hub forming pressurization mechanism includes a mold clamping press mechanism and a constraining frame 41 . The constraining frame 41 is a combined structure with sufficient strength and rigidity. The lower part of the constraining frame 41 is a bottom plate for installing the lower mold of the mold. The sides of the constraining frame 41 are two vertical plates, which are rigidly connected to the base plate; the upper part of the constraining frame 41 has two front and rear beams to constrain the vertical plate laterally and prevent the vertical plate from being deformed by force.

[0030] The clamping mold pressing mechanism includes a connector 11 and a holder 31, and the upper mold 51 is connected to the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com