A hydraulic press for wheel hub forming

A technology of hydraulic presses and hubs, applied in the field of hydraulic presses, can solve the problems of unusable, large space and small working stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the drawings.

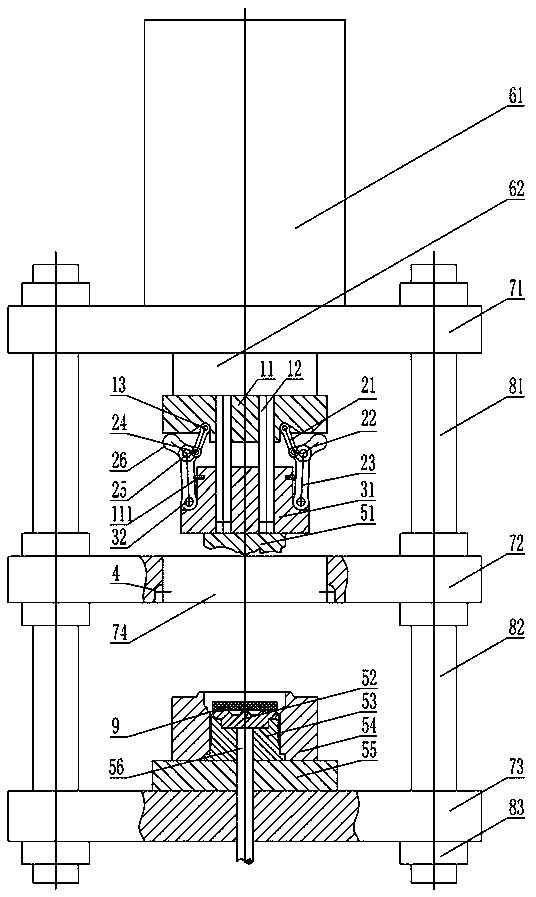

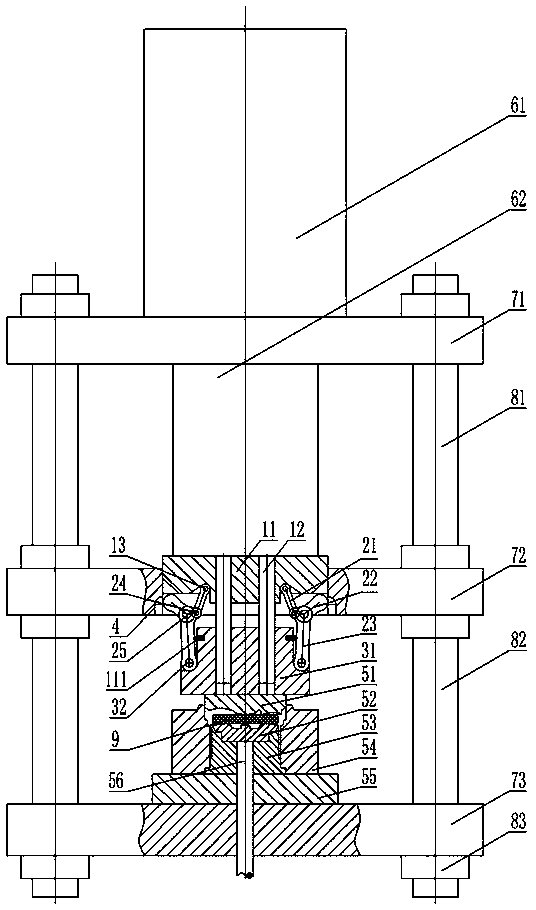

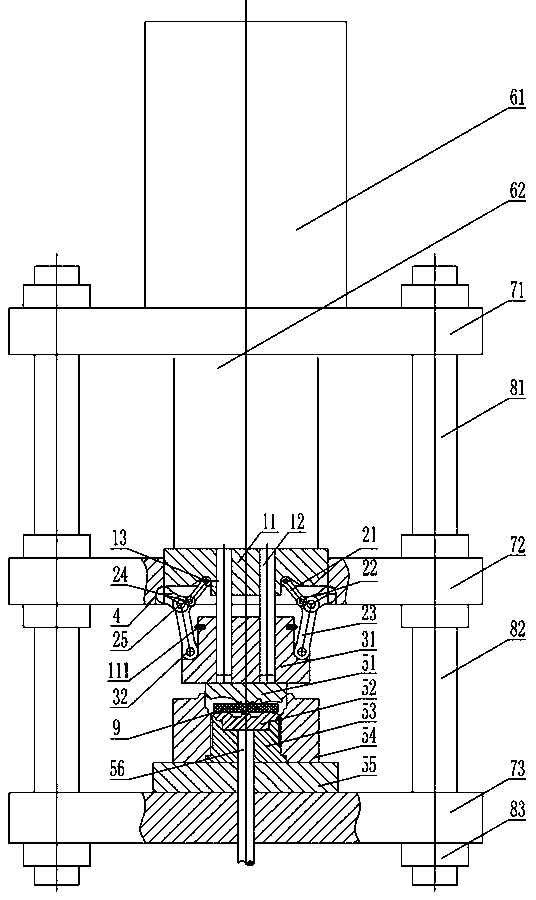

[0025] The first embodiment of the hydraulic press for forming a wheel hub of the present invention is used in a situation where a large operating space is required and a force stroke is small, such as a hub extrusion forming. Such as Figure 1 to Figure 6 As shown, the hydraulic press includes a frame. The frame includes a vertical column and an upper beam 71, a middle beam 72, and a lower beam 73 arranged at intervals along the axial direction of the column. The column includes a connection between the upper beam 71 and the middle beam 72. The upper pull rod 81 of the upper beam and the lower beam 82 connecting the middle beam 72 and the lower beam 73 are fixedly equipped with a hydraulic cylinder 61, and the piston rod 62 of the hydraulic cylinder 61 extends downward. An ejector cylinder is fixed under the lower beam 73. When in use, the lower beam 73 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com