A supercharging device and supercharging mechanism thereof

A technology of hydraulic press and connecting rod mechanism, which is applied in forging/pressing/hammer device, driving device of forging press, forging press, etc. It can solve the problems of low processing efficiency, inability to have large mold opening space, small stroke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

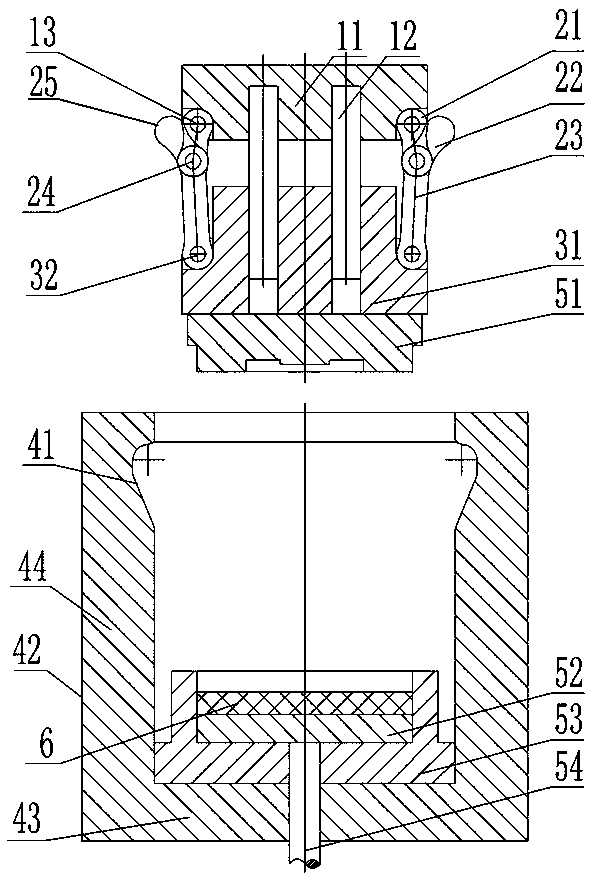

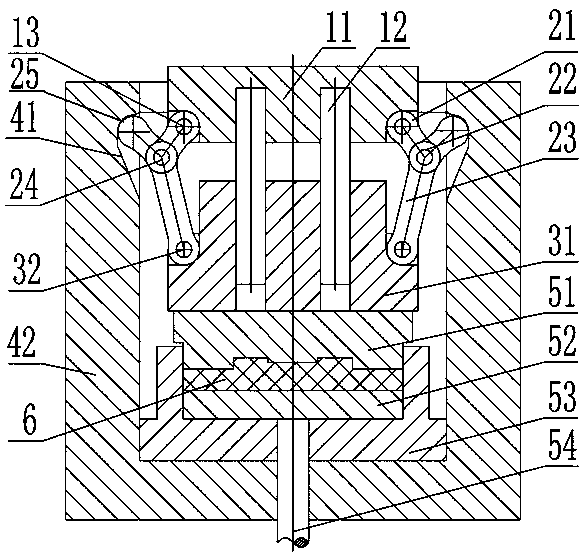

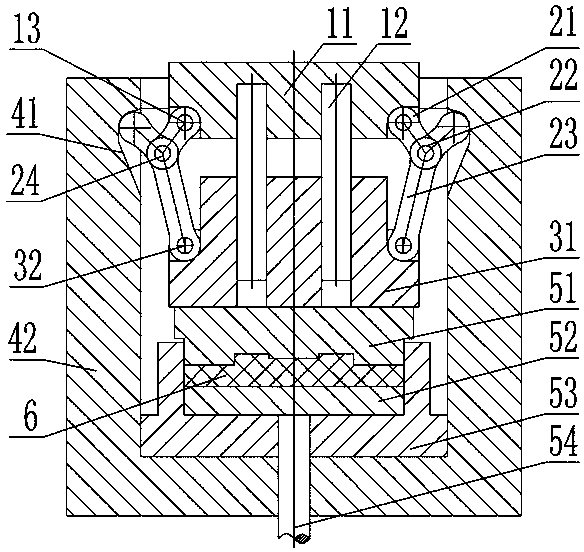

[0030] Embodiment 1 of the booster mechanism of the present invention, the booster mechanism is used in the liquid die forging process of large workpieces. like Figure 1 to Figure 6 As shown, the pressurizing mechanism includes a mold clamping and pressing mechanism installed on the movable beam of the hydraulic press and a constraint frame 42 installed on the workbench of the hydraulic press. The specific structure is as figure 1 , figure 2 , image 3 and Figure 4 As shown, the constraining frame 42 is a combined structure. The constraining frame 42 includes a bottom plate 43 and a side plate 44 fixedly connected to the bottom plate 43. The bottom plate 43 is used to install the lower die of the liquid forging die. perforated. The side plate 44 is rigidly connected to the bottom plate 43 , and a cross bar is connected above the side plate 44 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com