Single-shaft turbo compressor

A turbo compressor, single-shaft technology, used in mechanical equipment, non-variable displacement pumps, non-displacement pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

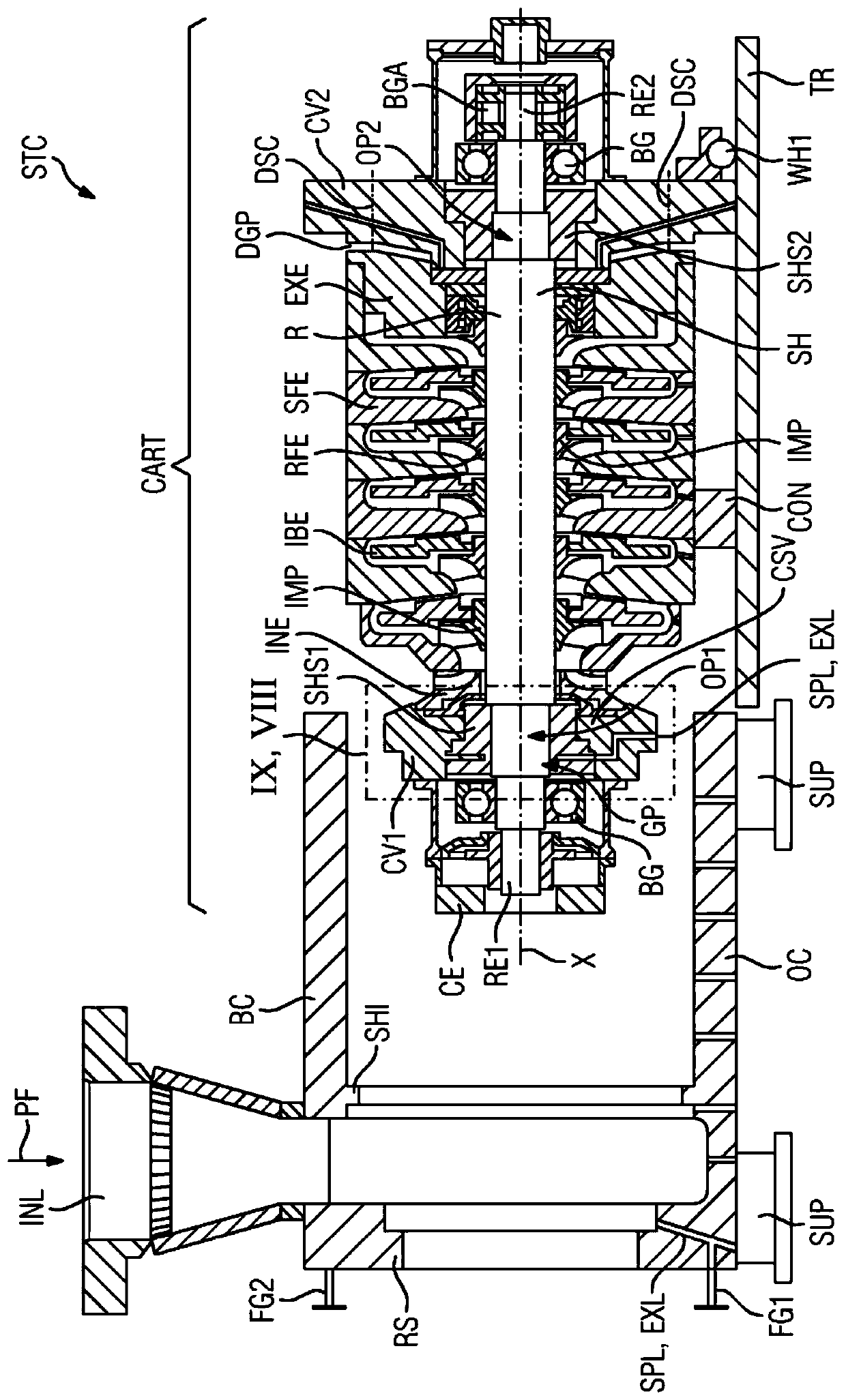

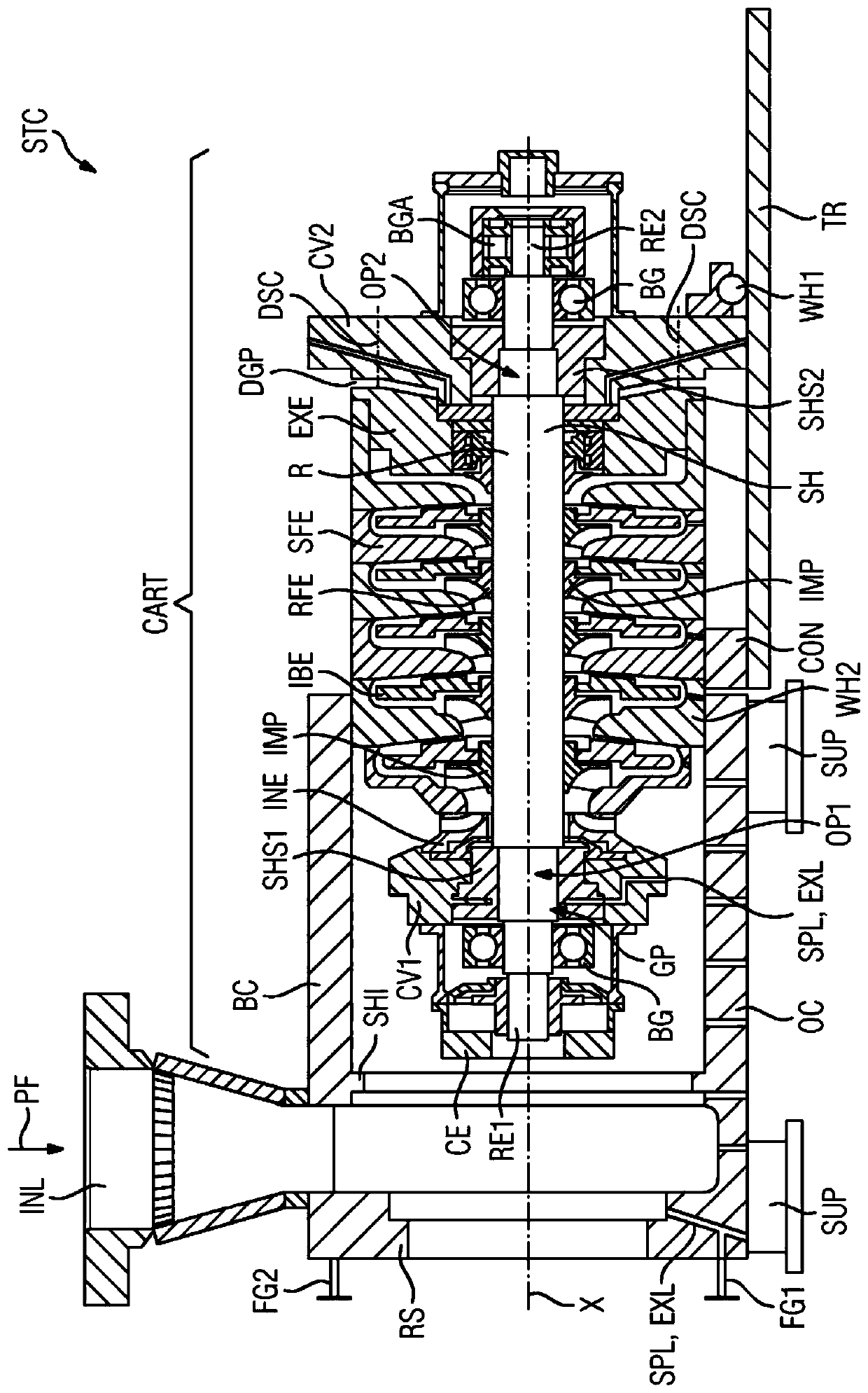

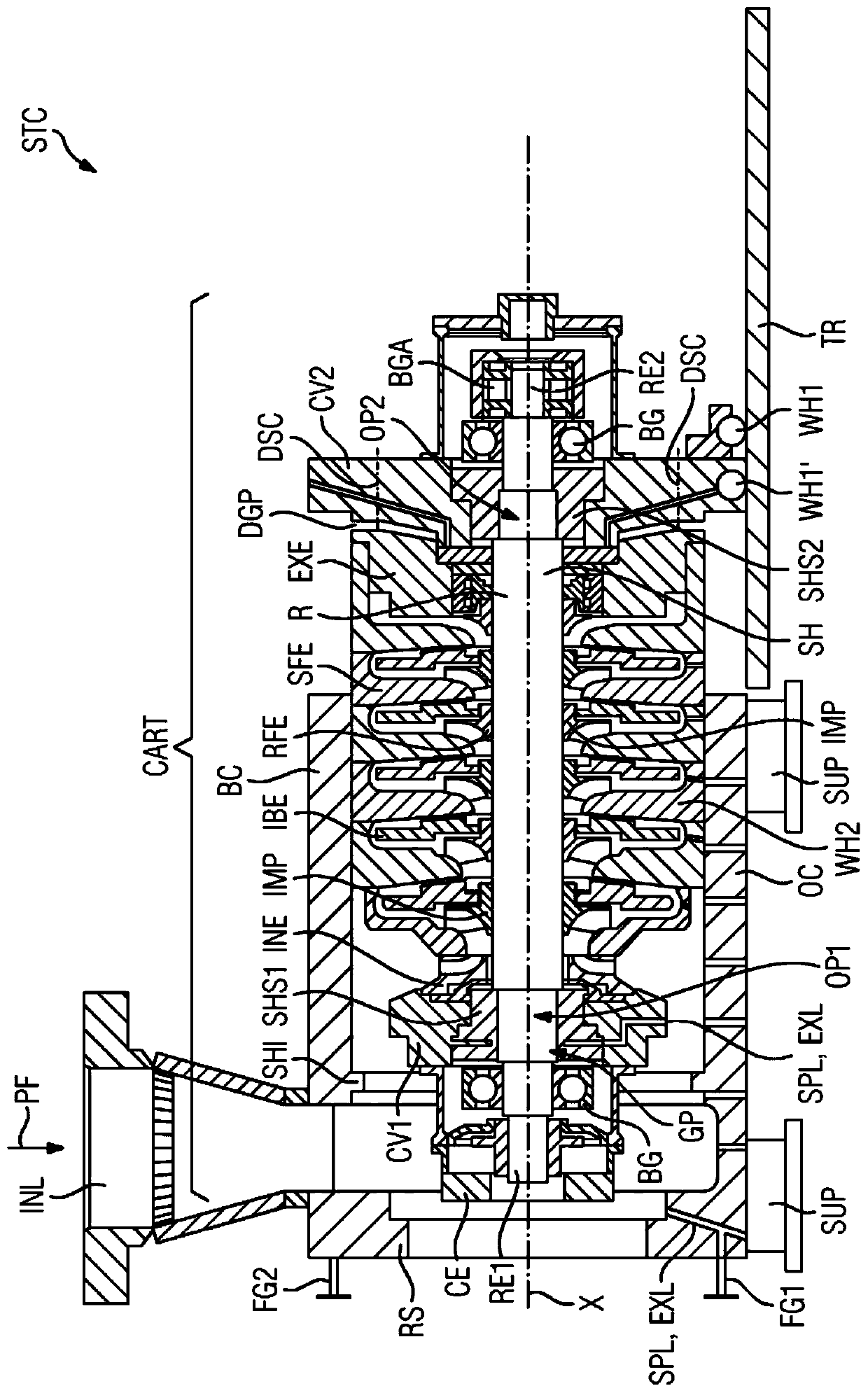

[0033] Figures 1 to 8 The single-shaft turbo compressors STC are each shown schematically in longitudinal section.

[0034] The single-shaft turbo compressor STC comprises a rotor R extending along an axis X, said rotor having a shaft SH and an impeller IMP (referenced only as an example) arranged on the shaft SH. The outer housing OC is provided with a first end-side cover CV1 and a second end-side cover CV2 in order to seal off the cover part BC of the outer housing OC. The covers CV1 , CV2 have openings OP1 , OP2 through which the respective ends of the rotor R extend. The rotor R is supported radially by means of bearings BG or radial bearings, wherein the axial bearings BGA hold the rotor R in a defined axial position.

[0035] The cover part BC is erected on the foot unit SUP along the axis X in a horizontally extending axial direction. The cover part BC has an inflow INL, wherein the existing outflow is not visible in the schematic representation. The process fluid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap