Steel bar grinding device with safety protection

A technology for safety protection and steel rods, which is applied in the direction of grinding machines, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve the problems of personal safety hazards of operators, excessive output of bars, and ejection of bars, etc. , to achieve the effect of simple structural improvement, convenient adjustment, and prevention of derailment and throwing out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

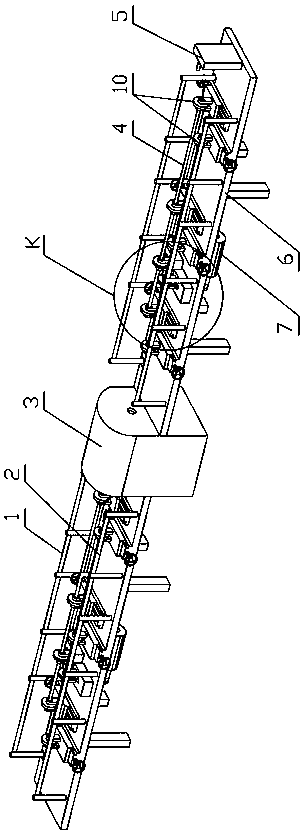

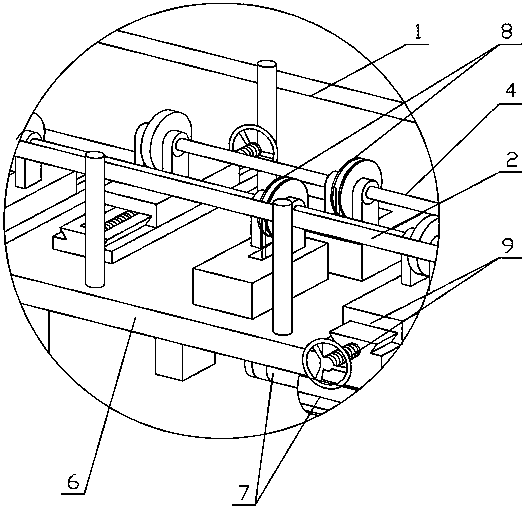

[0014] The present invention is a steel rod grinding device with safety protection, which has a steel rod centerless grinder 3. The feed end and the discharge end of the steel rod centerless grinder are respectively provided with a feed device and a discharge device. The device and the discharge device each include a material table 6, and several groups of steel rod conveying rollers 10 are arranged in a staggered shape on both sides of the material table. The steel rod conveying rollers on each side are all connected by a synchronous shaft 4, and the synchronous shaft It is driven by the driving roller 8, the driving motor 7 and the motor controller arranged at the bottom of the material platform, and guardrails A2 and B1 are respectively arranged on both sides of the material platform along the traveling direction of the steel bar, wherein the guardrail B is for rotating and opening. Combined guardrail; the tail end of the material table in the discharge device is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com