A lifting push-pull sealing rubber strip

A technology of sealing rubber strips and sealing strips, which is applied in the direction of sealing devices and wing leaf layout, etc., which can solve the problems of unfavorable energy saving, decreased air tightness, and reduced sealing tightness, so as to achieve reduced tightness, simple structure, and improved sealing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

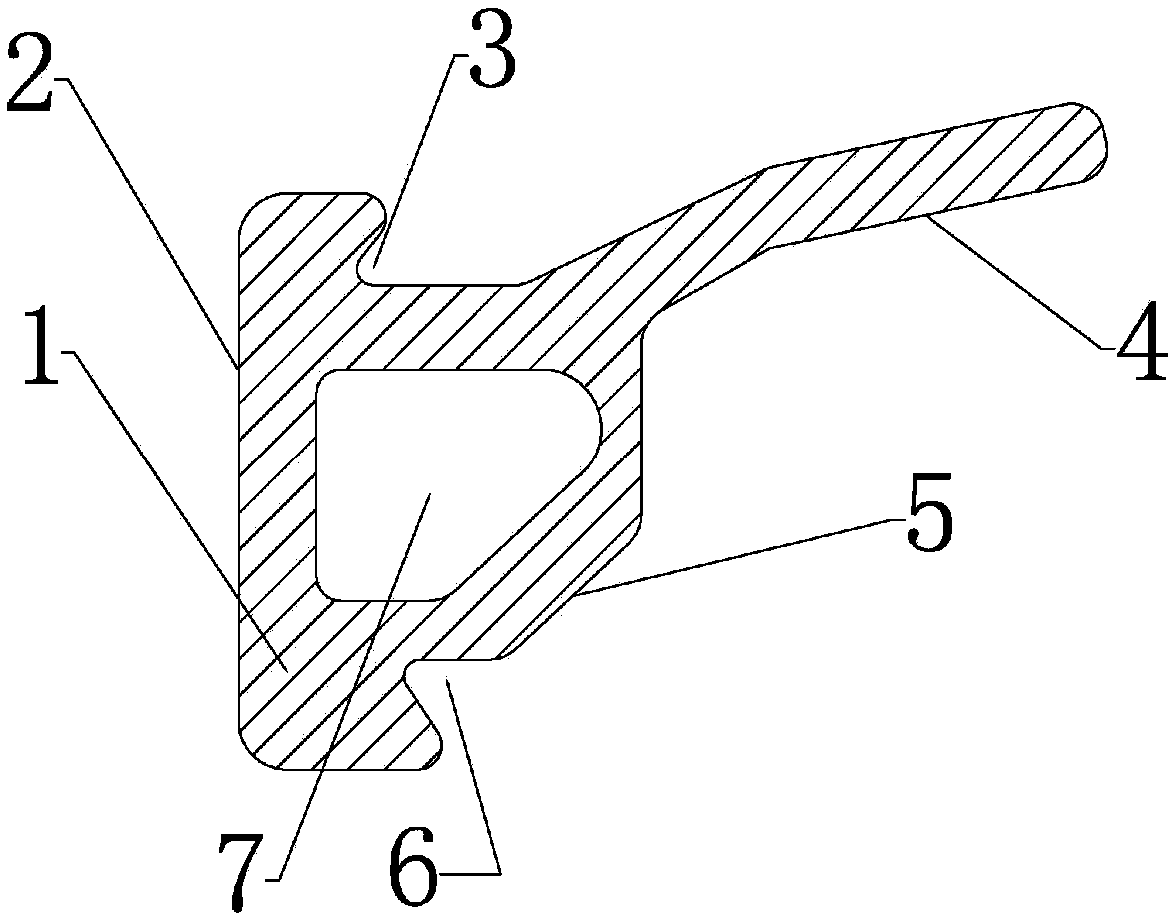

[0014] Such as figure 1 with figure 2 As shown, the present invention is a lifting push-pull sealing strip, including a body 1, the body 1 includes a mounting portion 3, a sealing portion 2 and a lip 4, the mounting portion 3, the sealing portion 2 and the lip 4 are integrated Type structure, the upper and lower sides of the mounting part 3 are provided with "V"-shaped mounting grooves 6, the sealing part 2 is a flat surface, the body 1 is provided with a cavity 7, and the upper right side of the body 1 is provided with A protruding lip4.

[0015] As a further improvement of this embodiment, the lower right side of the main body 1 is provided with a chamfer.

[0016] As a further improvement of this embodiment, the angle between the lip 4 and the mounting portion 3 is 130°-160°.

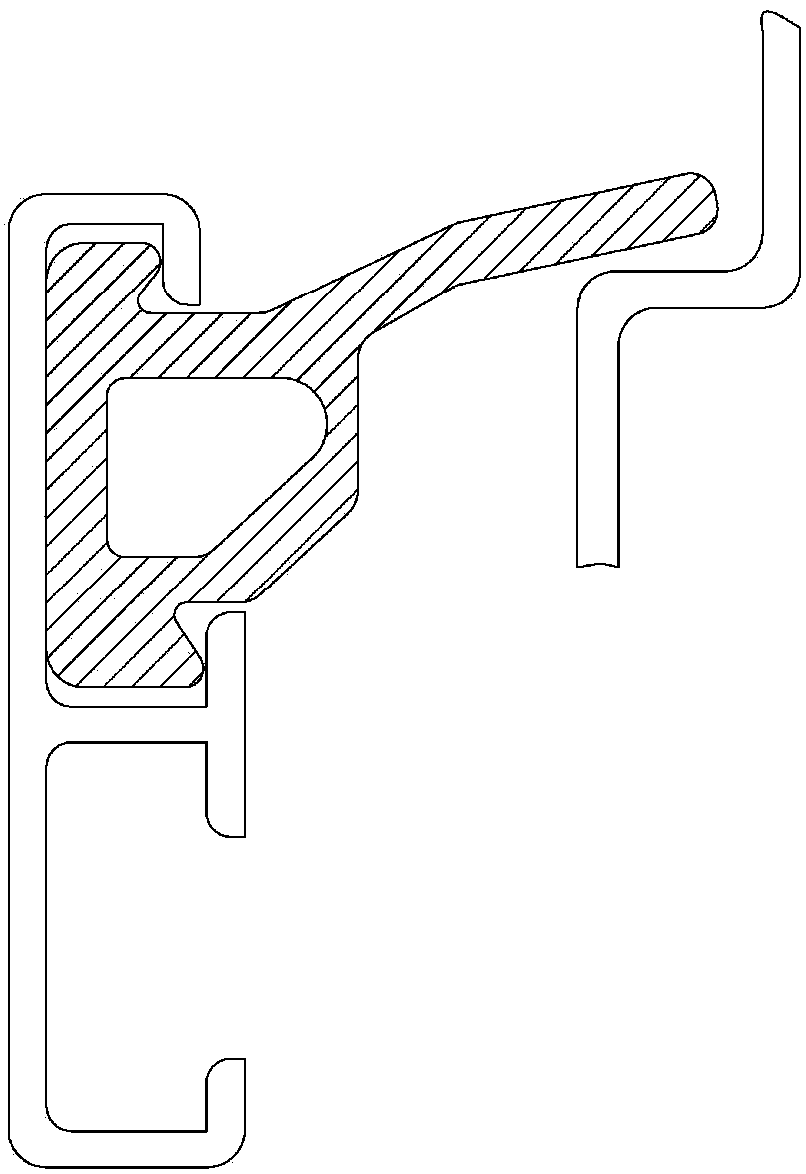

[0017] The working process of this example: install the sealant strip around the window frame through the installation part 3, the upper and lower installation grooves 6 of the installation part 3 are de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com