Brush-making machine and a hair bundle collecting method

A technology for bristle bundles and brush making machines, which can be applied to brushes, brush bodies, household components, etc., and can solve problems such as insufficient reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

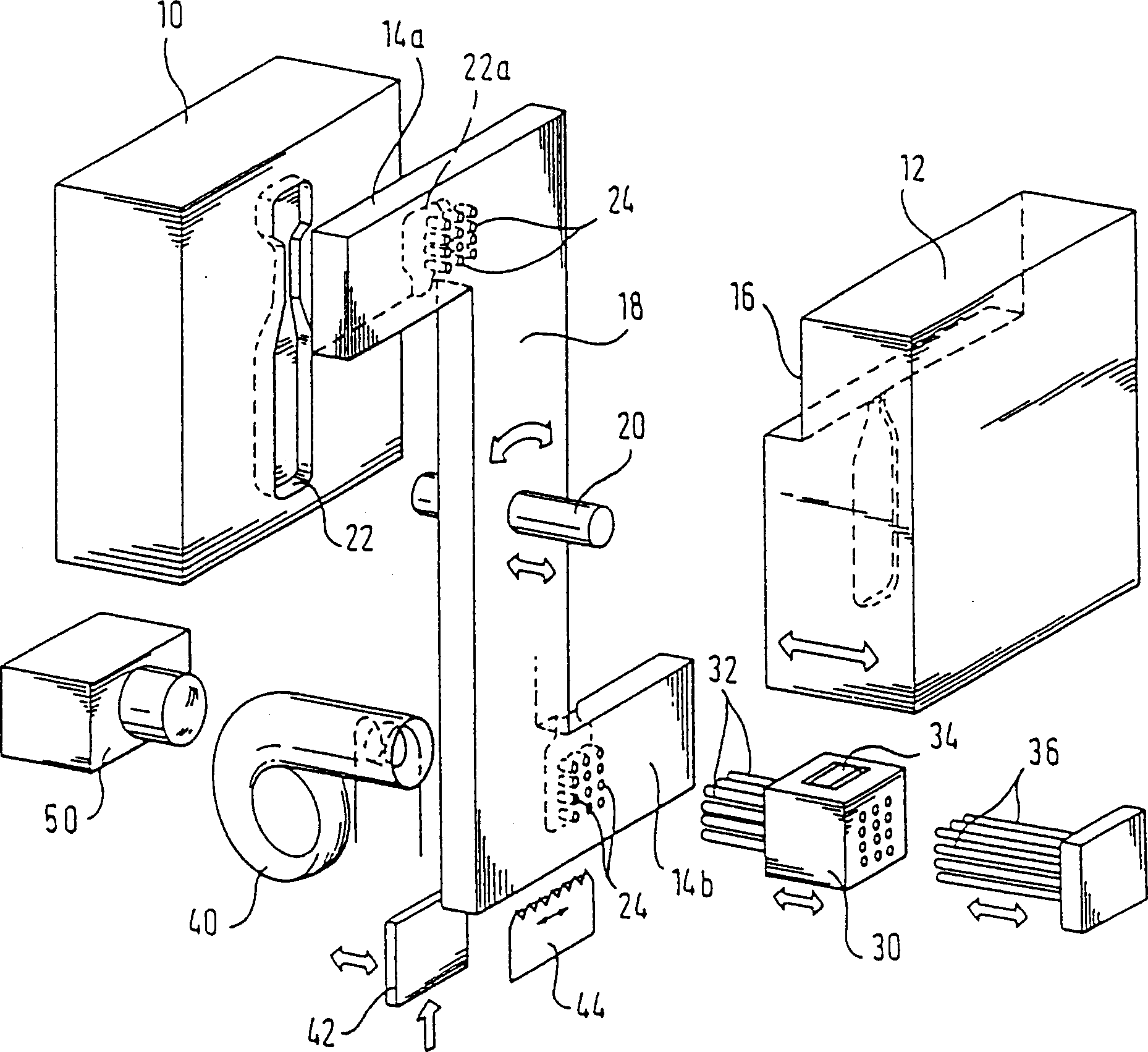

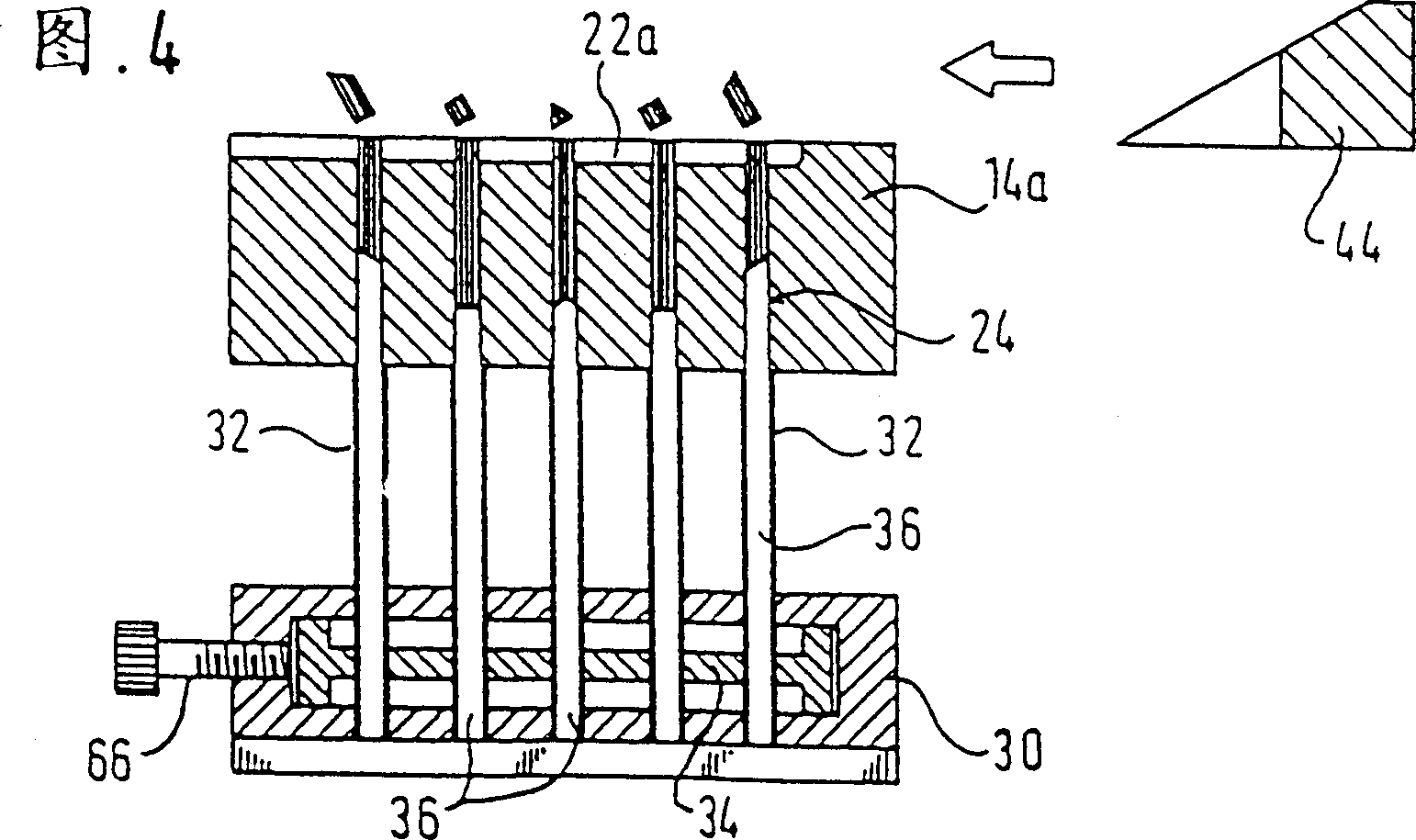

[0033]Figure 1 shows the main elements of a brush-making machine for the production of toothbrushes. One of these elements is a mold comprising a first fixed mold part 10, a second movable mold part 12, and a pair of cross-opposed mold parts fitted in recesses 16 of the first or second mold part. 14a, 14b. The cross-opposite mold parts 14a, 14b are connected to the ends of a dual-arm support 18, and the double-arm support 18 is mounted to be rotatable around an axis 20 and reciprocating along the axis 20. The mold parts 10, 12 and 14a (or 14b) form a mold cavity having the shape of the toothbrush body to be molded. The opposing mold parts 14a, 14b have a cavity profile which corresponds to the head of the toothbrush and in particular to the side of the toothbrush head on which the bristles protrude after completion of the molding process. A number of bristle tuft insertion openings 24 are therefore provided on the mold parts 14a, 14b, which penetrate the mold parts and open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com