Garbage bin

A technology for trash cans and outer buckets, applied in the field of trash cans, can solve the problems of overload compression of the internal compression device, poor compression movement stability, affecting the service life and reliability of the compression device, etc., so as to ensure the stability of movement and improve the user Experience, ensure the stability of garbage compression and the effect of working effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

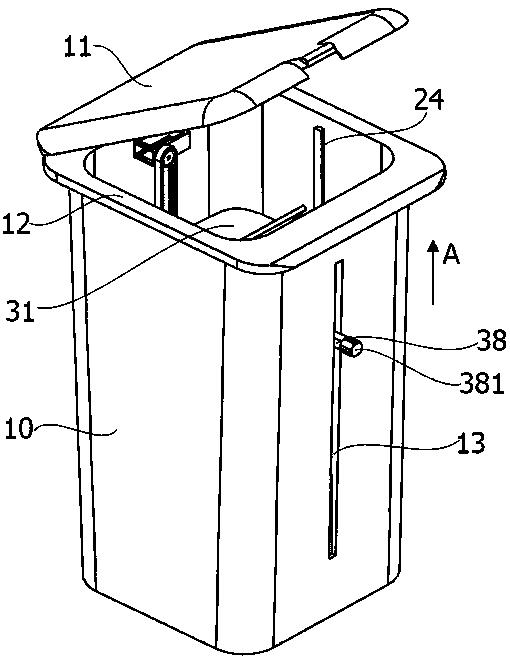

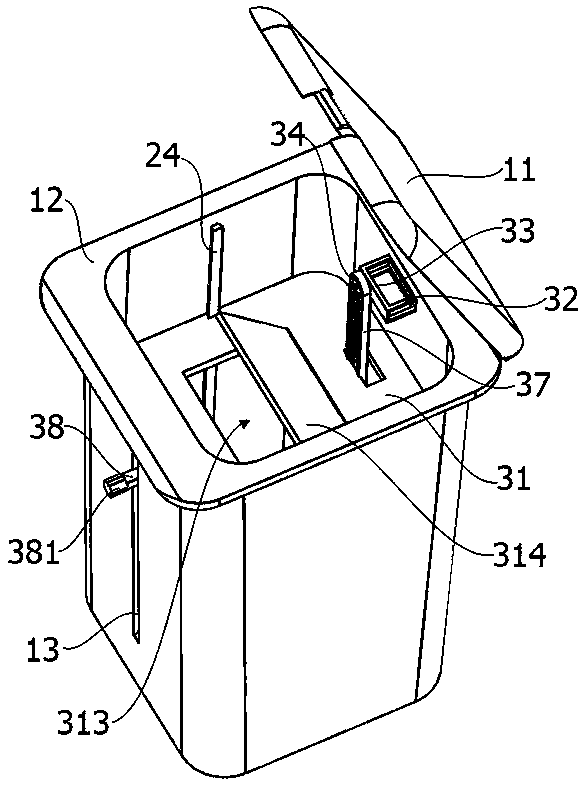

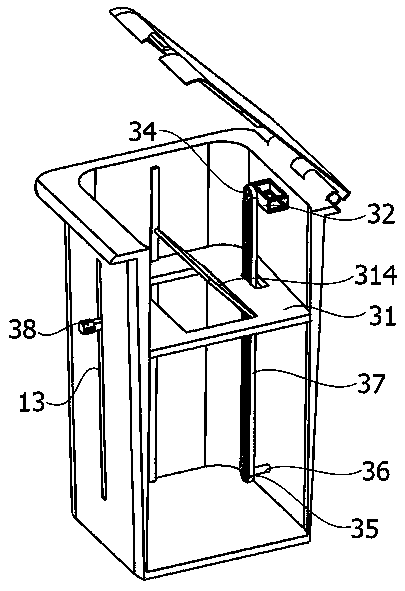

[0018] The application of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. See Figure 1-6 As shown, the application of the present invention provides a trash can, including an outer bucket 10 and a door cover 11 . The inside of the outer barrel 10 is a hollow cavity, and the outer barrel 10 is used for storing garbage. Flanges 12 are arranged on the upper edge of the outer tub 10, and the door cover 11 is hingedly connected with the flaps 12, so that the door cover 11 is hinged on the outer tub 10 relative to the rotation of the outer tub 10, and then the outer tub 10 can be opened or closed. The cavity is convenient for the user to put garbage into the outer bucket 10 or close it and put it into the outer bucket 10.

[0019] In order to reduce the occupied space of the rubbish stored in the outer barrel 10 and increase the storage capacity of the rubbish in the outer barrel 10, in the em...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap