Installation device for prefabricated pipe pile and pile cap in municipal engineering

A technology of prefabricated pipe piles and installation devices, which can be used in foundation structure engineering, sheet pile walls, soil protection, etc., and can solve problems such as damage, large self-weight of pile caps, and coaxial alignment of installation grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

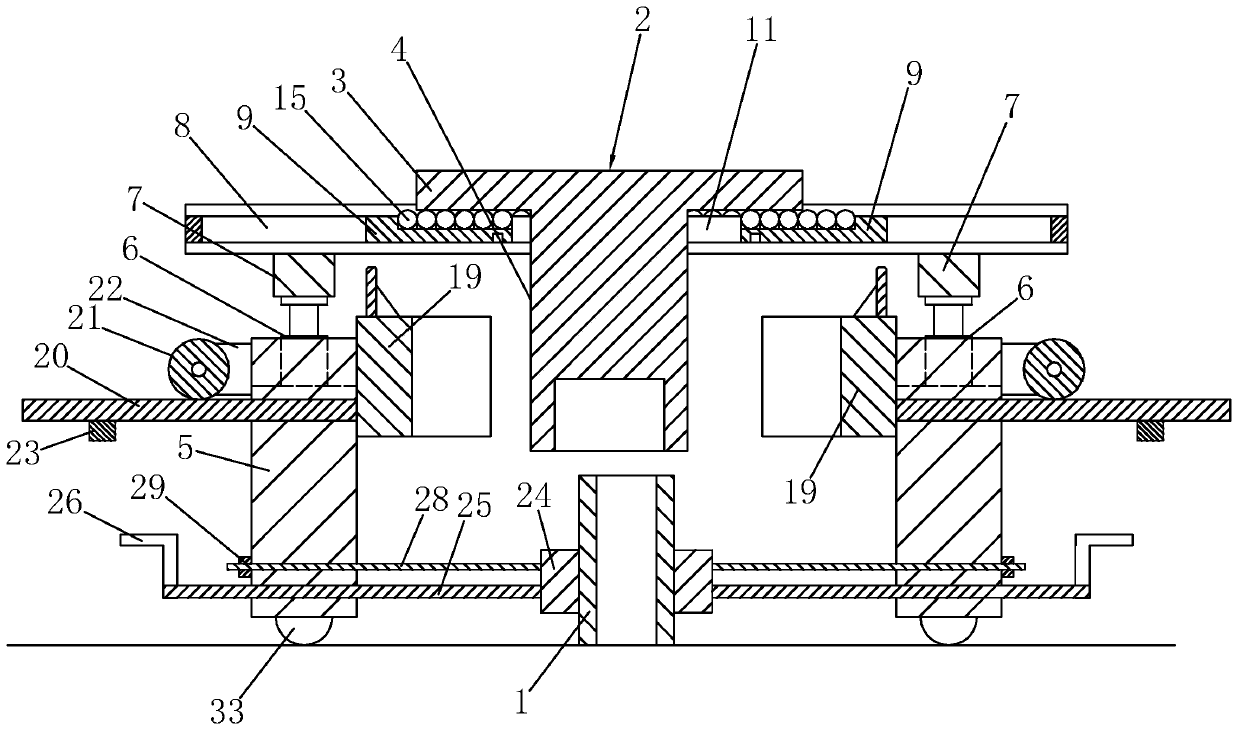

[0037] Example: a municipal engineering prefabricated pipe pile and pile cap installation device, such as figure 1 As shown, the bracket includes a bracket installed above the pipe pile 1. The bracket includes two side plates 5, and the upper part of the two side plates 5 is equipped with a synchronization jack 6. The piston of the synchronization jack 6 is connected with a cross beam 7, and the cross beam 7 is installed There are two slide rails 8 arranged in parallel, and two symmetrical positioning plates 9 slide in the slide rail 8.

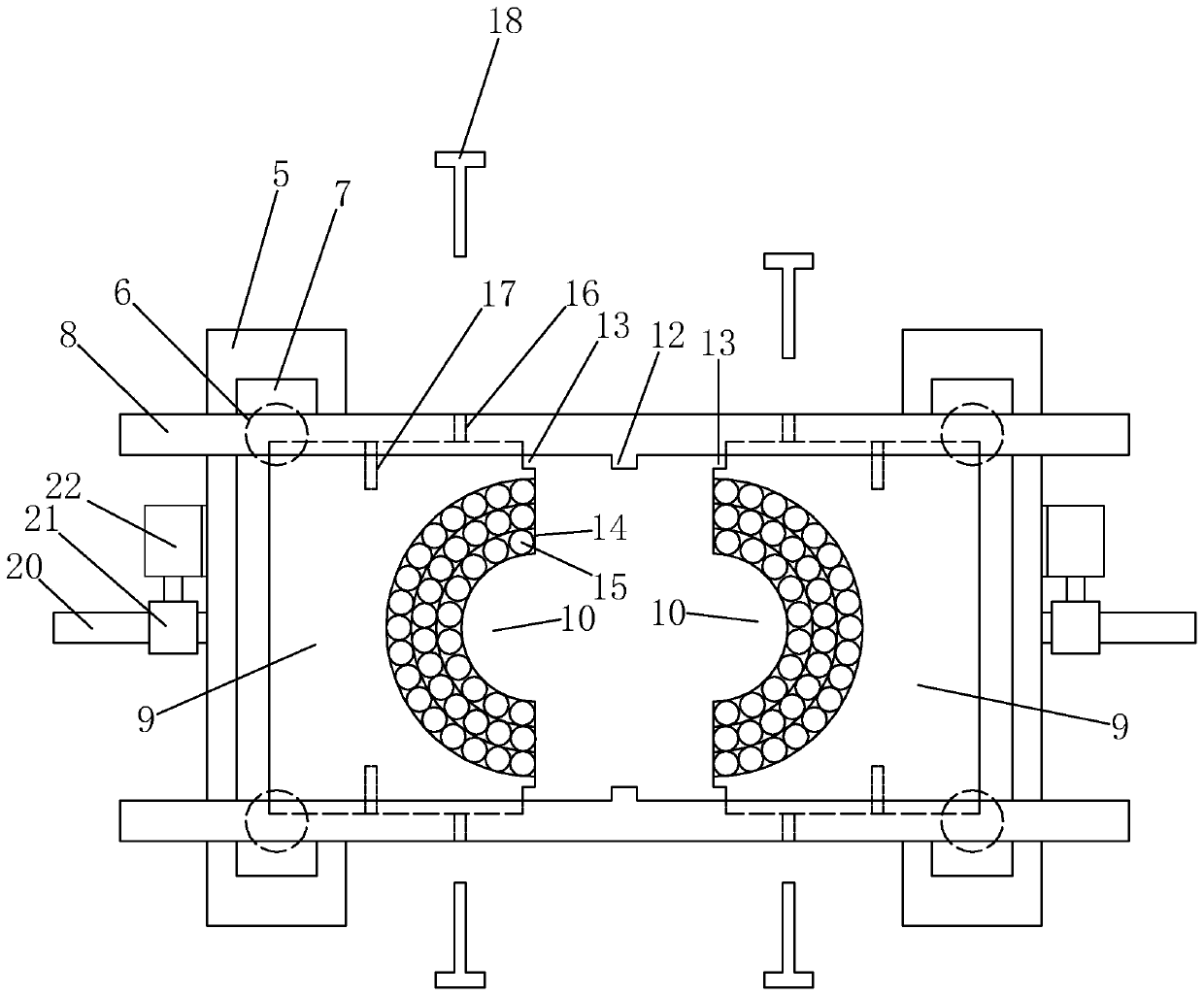

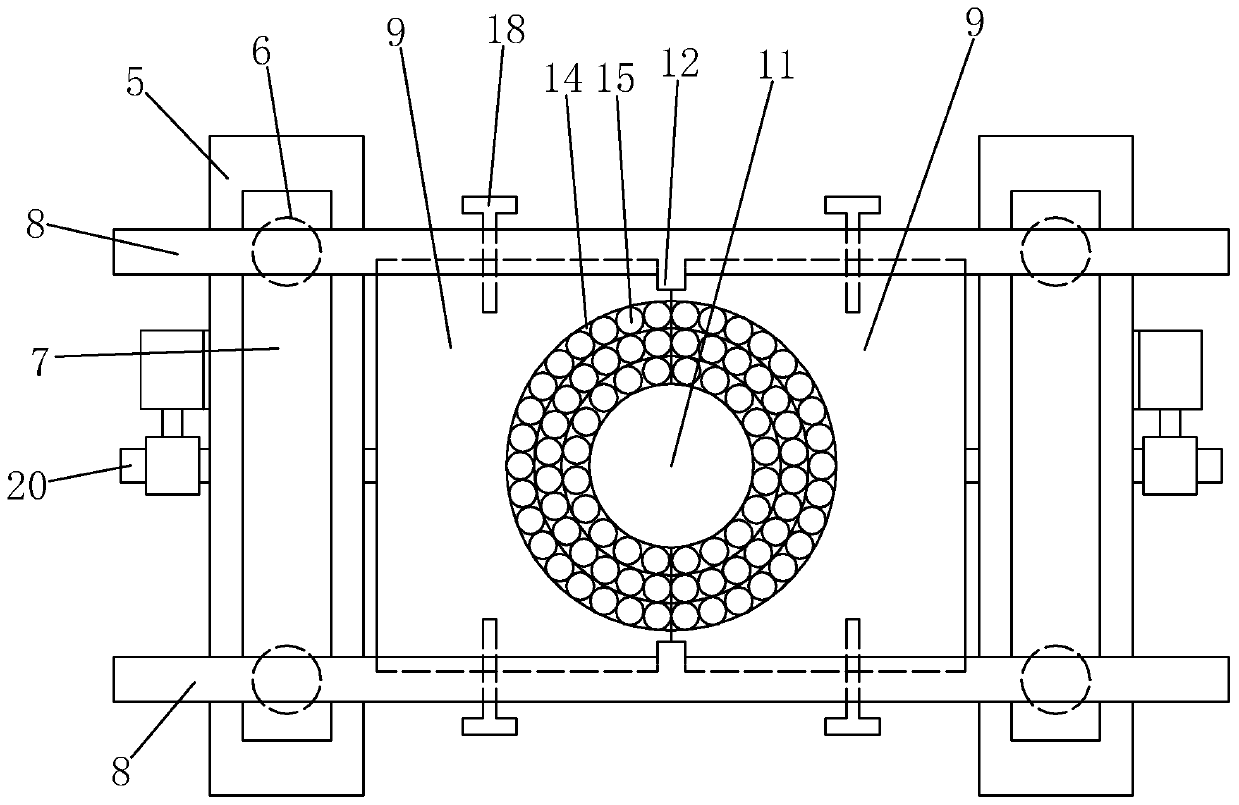

[0038] Such as Figure 2-3 As shown, the two positioning plates 9 are provided with a semicircular hole 10 in the middle of the opposite side, and the semicircular holes 10 of the two positioning plates 9 are spliced to form a mounting hole 11 for the fixing sleeve 4 of the pile cap 2 to be inserted; the slide rail 8 A positioning block 12 is provided in the middle of the two side plates 5, and a positioning groove 13 is provided on the opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com