Flexible light guide installing structure of LED car light

A technology of LED car lights and installation structure, which is applied in the field of car lights, can solve problems such as limited shape, large gap requirements, high-power light source shape design, installation contradictions, etc., to solve the problem of matching size, fast assembly, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, further description will be given below in conjunction with specific examples.

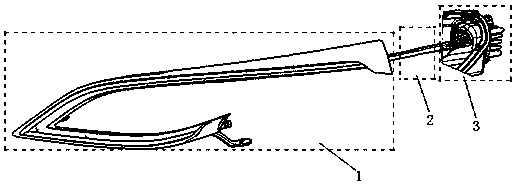

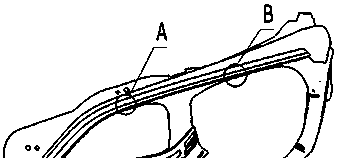

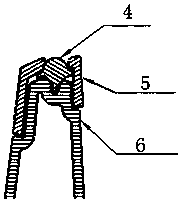

[0021] At present, the matching installation method and principle of automobile LED lights are as follows: Figure 8-9 As shown, in order to achieve a stable and reliable connection and fixation between the overall appearance that meets the styling requirements, the lamp housing and the light guide, there will be multiple fully constrained parts. First of all, both ends of the light guide are in a fully constrained state (that is, the light guide as a whole is in an over-constrained state). Through dimensional chain analysis, the dimensional chain of this installation structure is a fully closed loop, which will make the installation process difficult or even impossible. Because if the installation of the light guide is completed first, and then it is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com