Monitoring probe, system and method for corrosion damage of pressure pipeline

A technology of pressure pipelines and probes, which is applied in the field of monitoring probes for corrosion damage of pressure pipelines, can solve problems such as excessively limited selectivity of monitoring probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

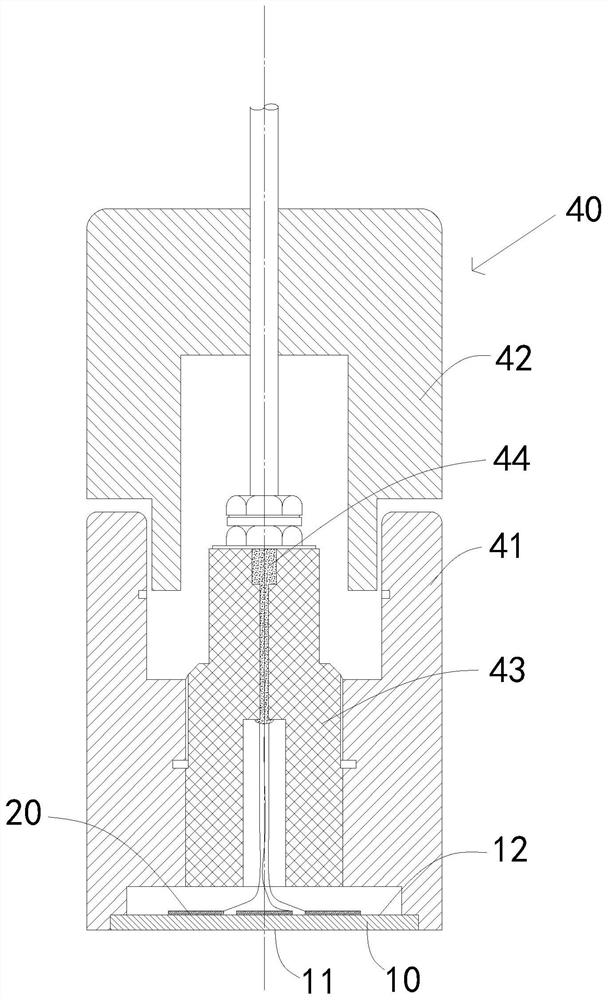

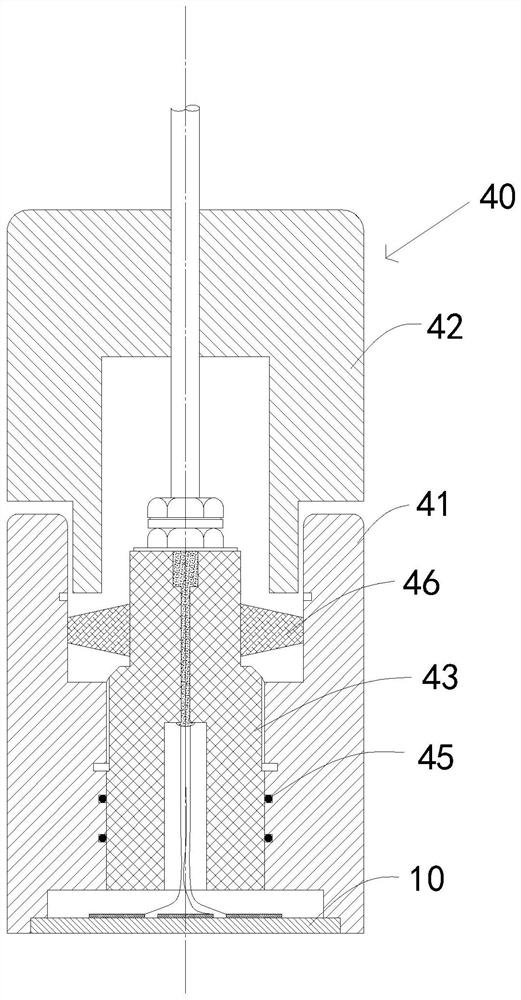

[0044] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

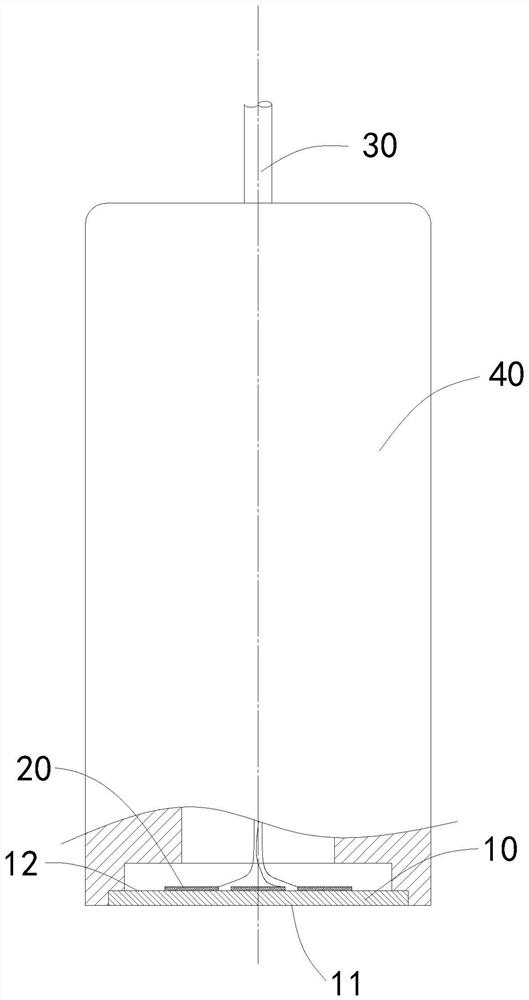

[0045] The invention provides a monitoring probe for corrosion damage of pressure pipelines, the first embodiment of the monitoring probe is as follows figure 1 As shown, it includes a corrosion sheet 10, a strain gauge 20, a strain data transmission cable 30 and a sealing assembly 40; the corrosion sheet 10 includes an upflow surface 11 and a detection surface 12, and the upflow surface 11 and the detection surface 12 are respectively arranged on the corrosion sheet 10 On the opposite sides, the upstream surface 11 is exposed outside the sealing assembly 40, the detection surface 12 is sealed in the sealing assembly 40, the material of the corrosion sheet 10 is the same as that of the pressure pipeline to be measured; the strain gauge 20 is sealed in the sealing assembly 40 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com