Connector assembly with shipping cap

一种连接器组件、电连接器的技术,应用在连接装置的零部件、连接、电气元件等方向,能够解决杠杆移位、杠杆被撞离等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

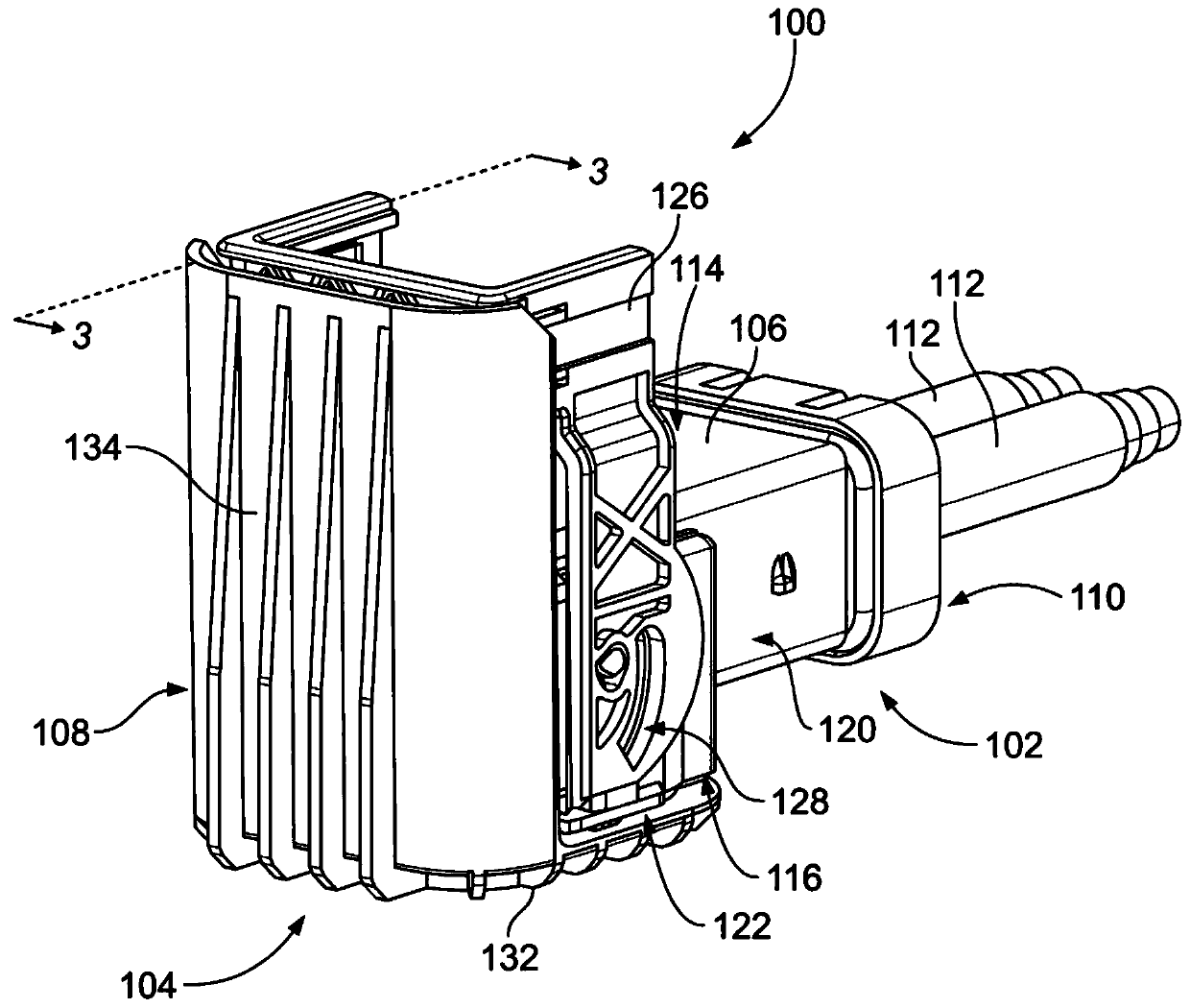

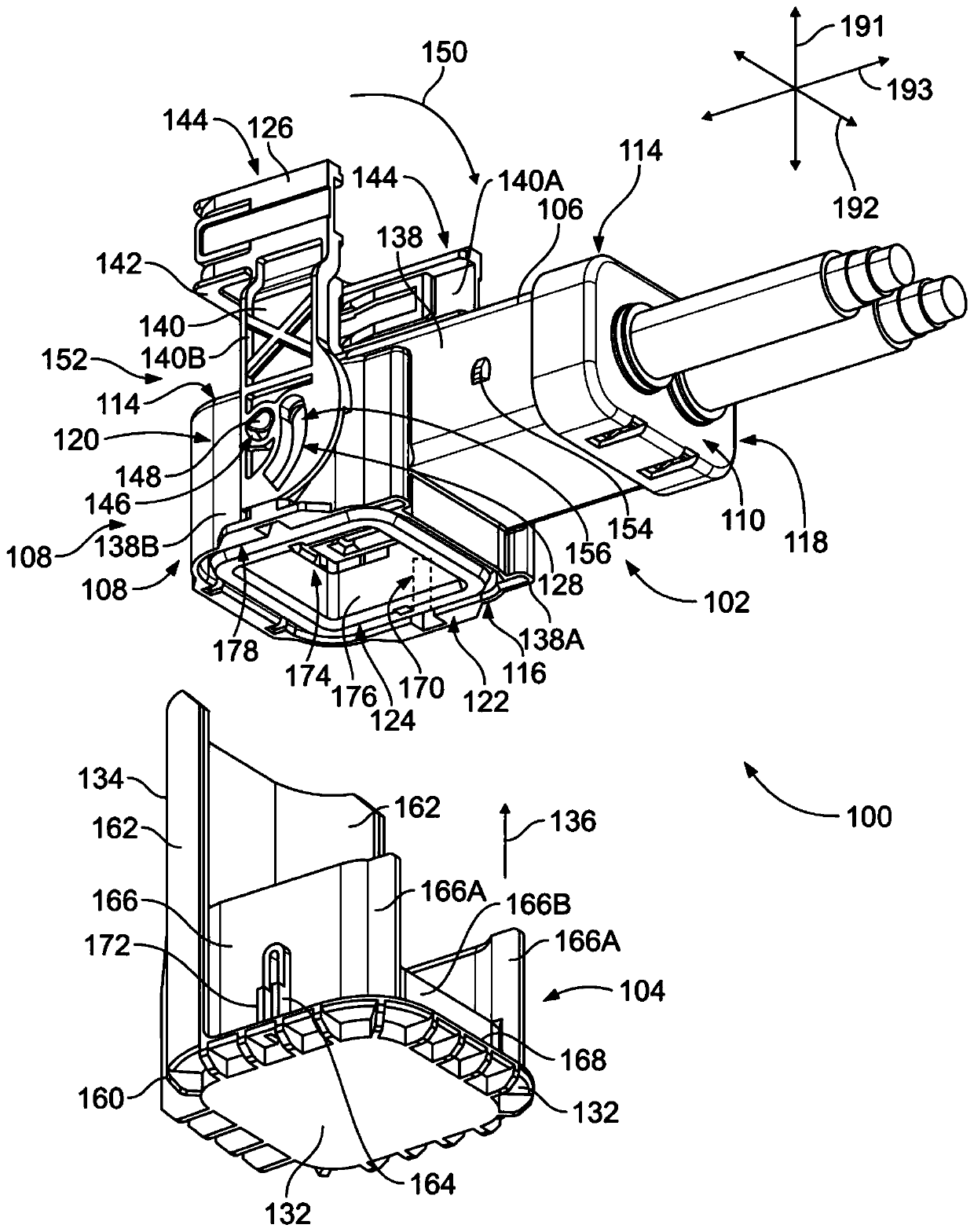

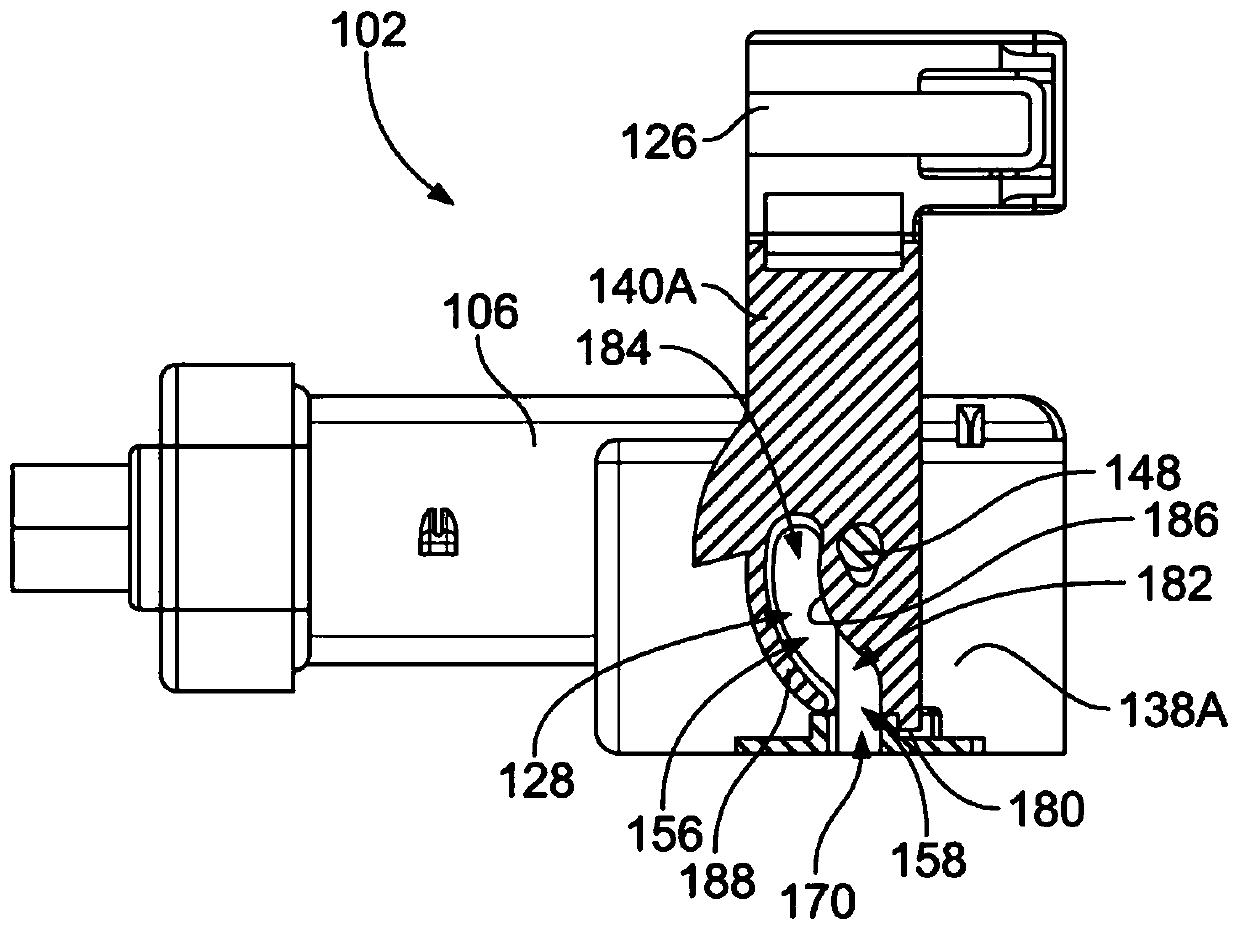

[0017] figure 1 is a top perspective view of connector assembly 100 according to an embodiment. The connector assembly 100 includes an electrical connector 102 and a shipping cap 104 . The electrical connector 102 includes a housing 106 extending between a front end 108 and an opposite rear end 110 . The electrical connector 102 mounts to one or more cables 112 or wires extending from the rear end 110 . Cable 112 may be part of a wiring harness.

[0018] Housing 106 includes a top side 114, a bottom side 116, a left side 118 ( figure 2 shown in ) and right side 120. As used herein, relative or spatial terms such as "top", "bottom", "front", "rear", "left" and "right" are used only to distinguish the referenced elements in connector assembly 100, and A particular location or orientation within the surrounding environment of connector assembly 100 is not necessarily required. In the illustrated embodiment, the electrical connector 102 defines a mating end 122 along the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com