Dynamic coal discharging method for fully mechanized top-coal caving mining

A fully mechanized caving and dynamic technology, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of low top coal recovery rate, top coal loss, incompatibility with the efficient and high recovery rate development of coal resources, etc. Mixed gangue rate, improve coal output efficiency, avoid the effect of repeated disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

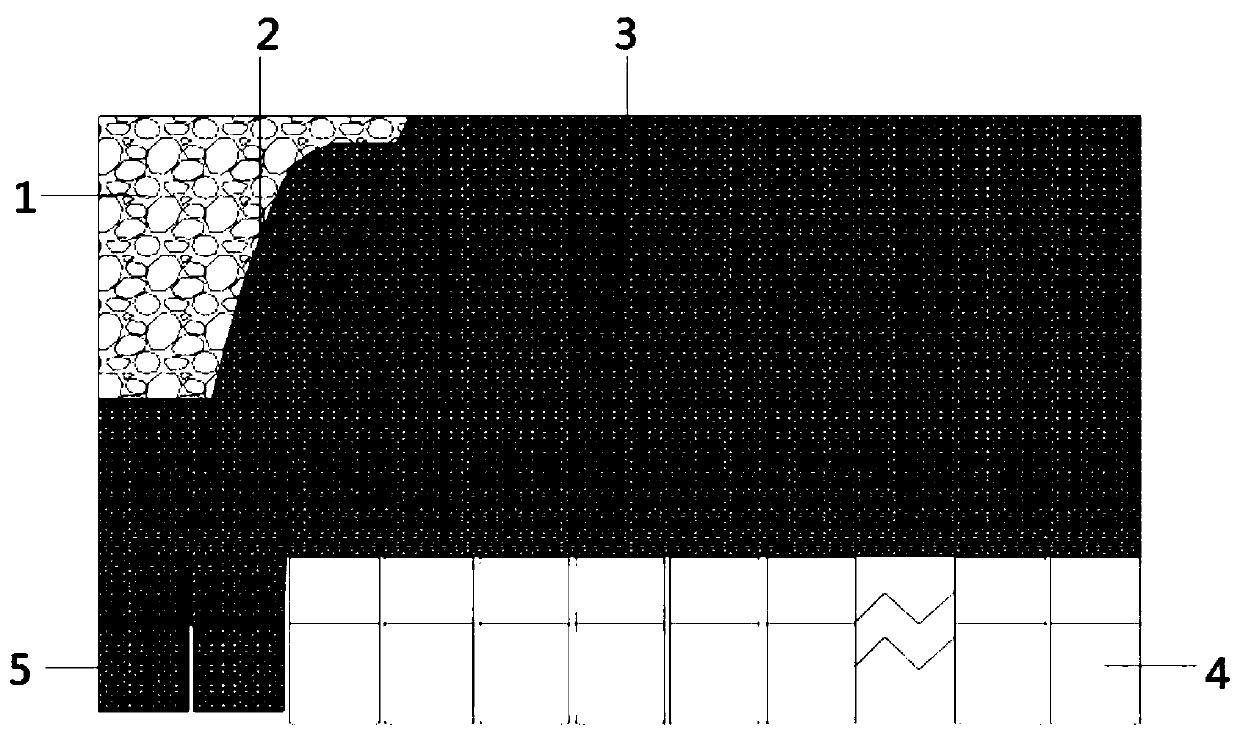

[0025] Such as Figure 1-Figure 4 Shown: present embodiment provides a kind of dynamic coal discharging method of fully mechanized caving mining, comprises following coal discharging steps,

[0026] S1: Number the hydraulic supports 4 on the fully-mechanized mining face to be mined as No. 1, No. 2, No. 3, ..., No. N, No. N+1, where N is an integer not less than 1;

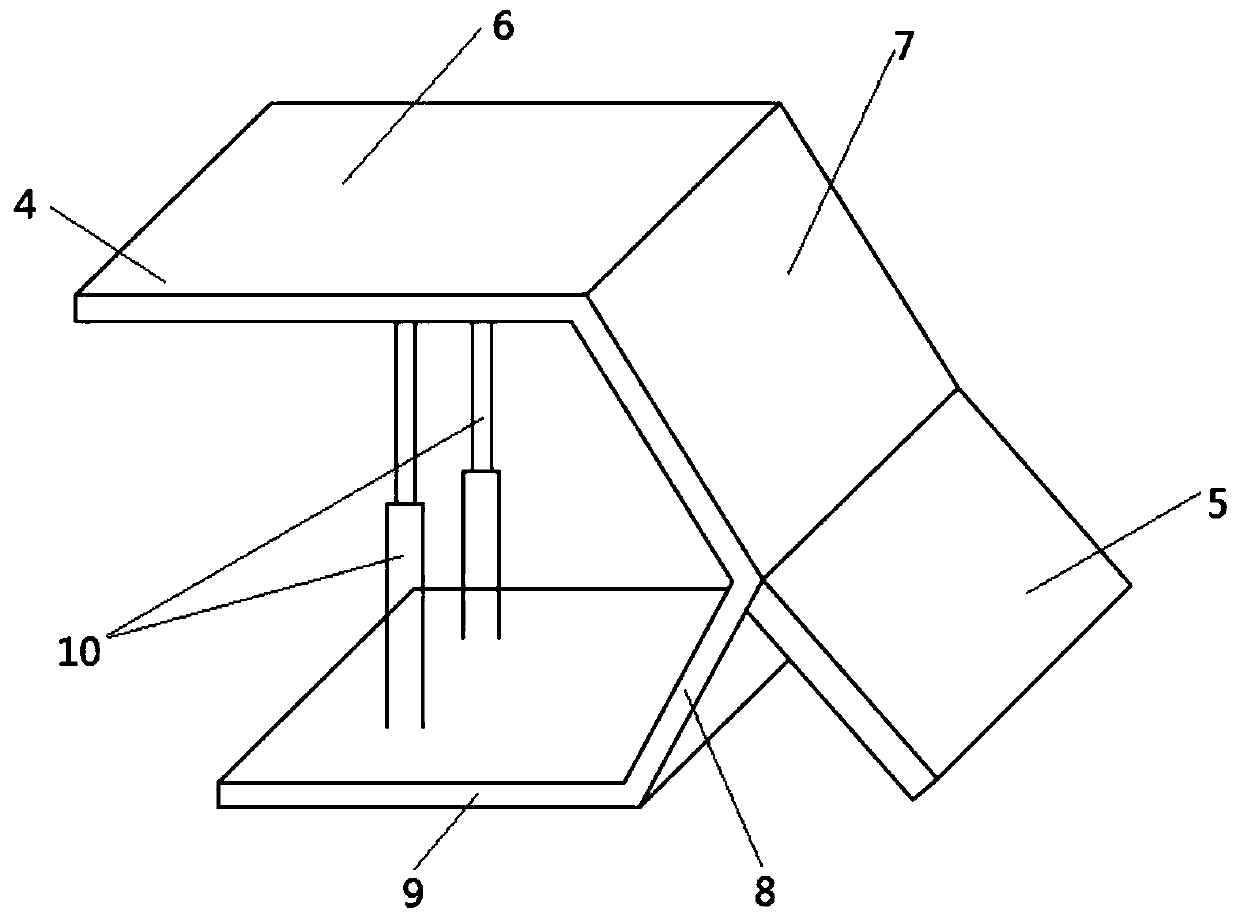

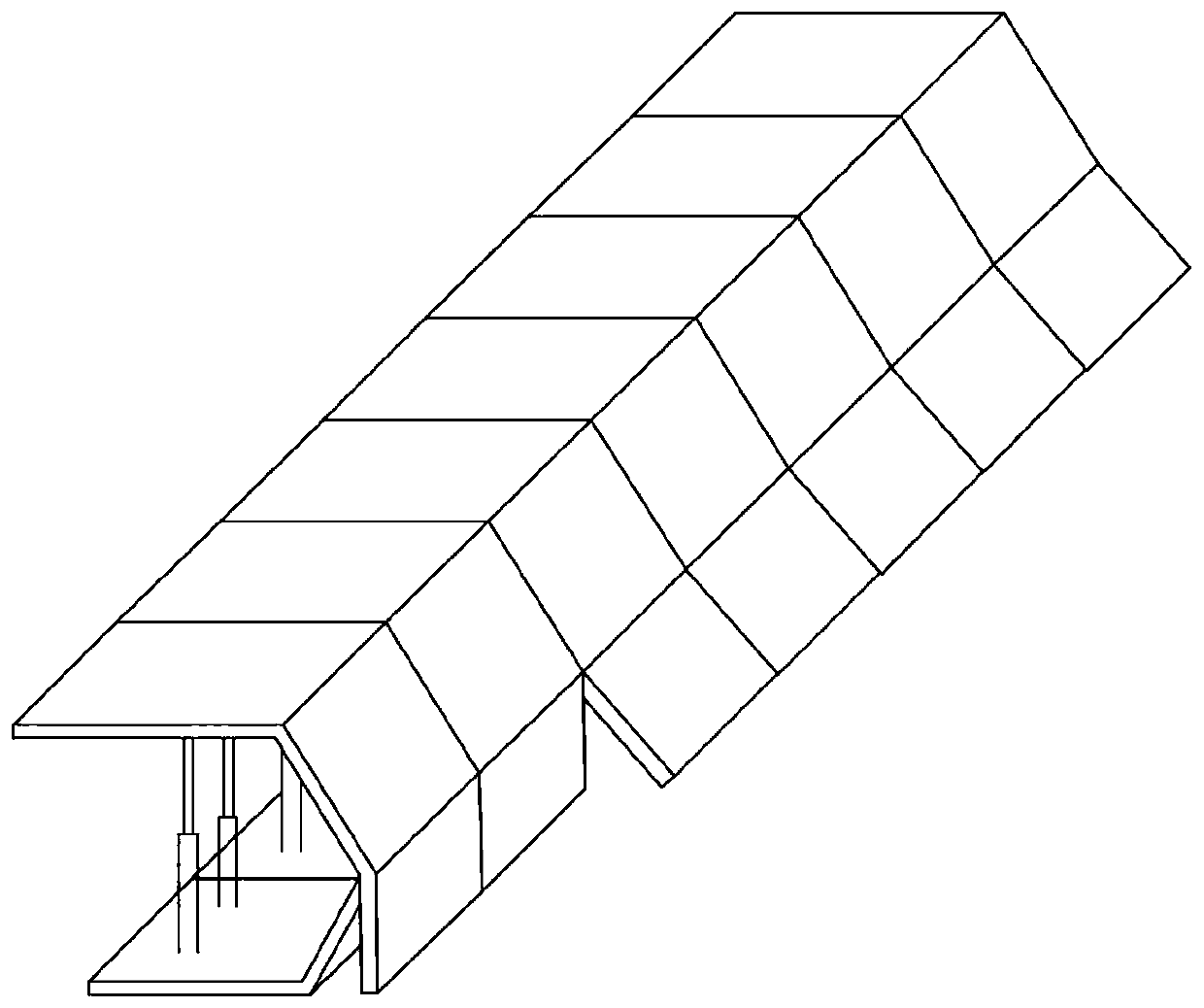

[0027] S2: The hydraulic support 4 includes a base 9, a tail beam 8, a cover beam 7, a column 10, a top beam 6, and a coal discharge plate 5, and the column 10 is fixed between the base 9 and the top beam 6, and the tail beam 8 and the base 9 side rotation connection, the upper end of the tail beam 8 is rotationally connected with the shield beam 7, the upper end of the shield beam 7 is rotationally connected with the top beam 6, and the coal discharge plate 5 is rotationally connected with the shield beam 7. According to the numbering sequence of the hydraulic support 4, first open No. 1 The coal discharge plate ...

Embodiment 2

[0030] The difference with Embodiment 1 is: according to the numbering sequence of the hydraulic supports 4, the coal discharge plates 5 of the No. 1 and No. 2 hydraulic supports 4 are first opened, and when the coal discharge plates 5 of the No. 1 and No. 2 hydraulic supports 4 set a certain amount of coal, Open the coal discharge plate 5 of No. 3 and No. 4 hydraulic supports 4 to discharge coal at the same time. When the coal discharge plate 5 of No. 3 and No. 4 hydraulic supports 4 discharges a certain amount of coal, open the coal discharge of No. 5 and No. 6 hydraulic supports 4 Plate 5 carries out coal discharge at the same time, and so on, when the coal discharge plate 5 of No. N-2 and N-1 hydraulic support 4 discharges a certain amount of coal, open the coal discharge plate 5 of No. N and N+1 hydraulic support 4 to carry out Simultaneously discharge coal, N is an integer not less than 2; at the same time, after each hydraulic support 4 coal discharge plate 5 sees gangue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com