Method of producing a cross car beam utilizing on-line shaping and piercing technology

A technology for automobiles, crossbeams, applied in the direction of connection between manufacturing tools, other manufacturing equipment/tools, superstructure subassemblies, etc., capable of solving problems such as deformation, poor positioning geometric dimensions and tolerances, poor fit and finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

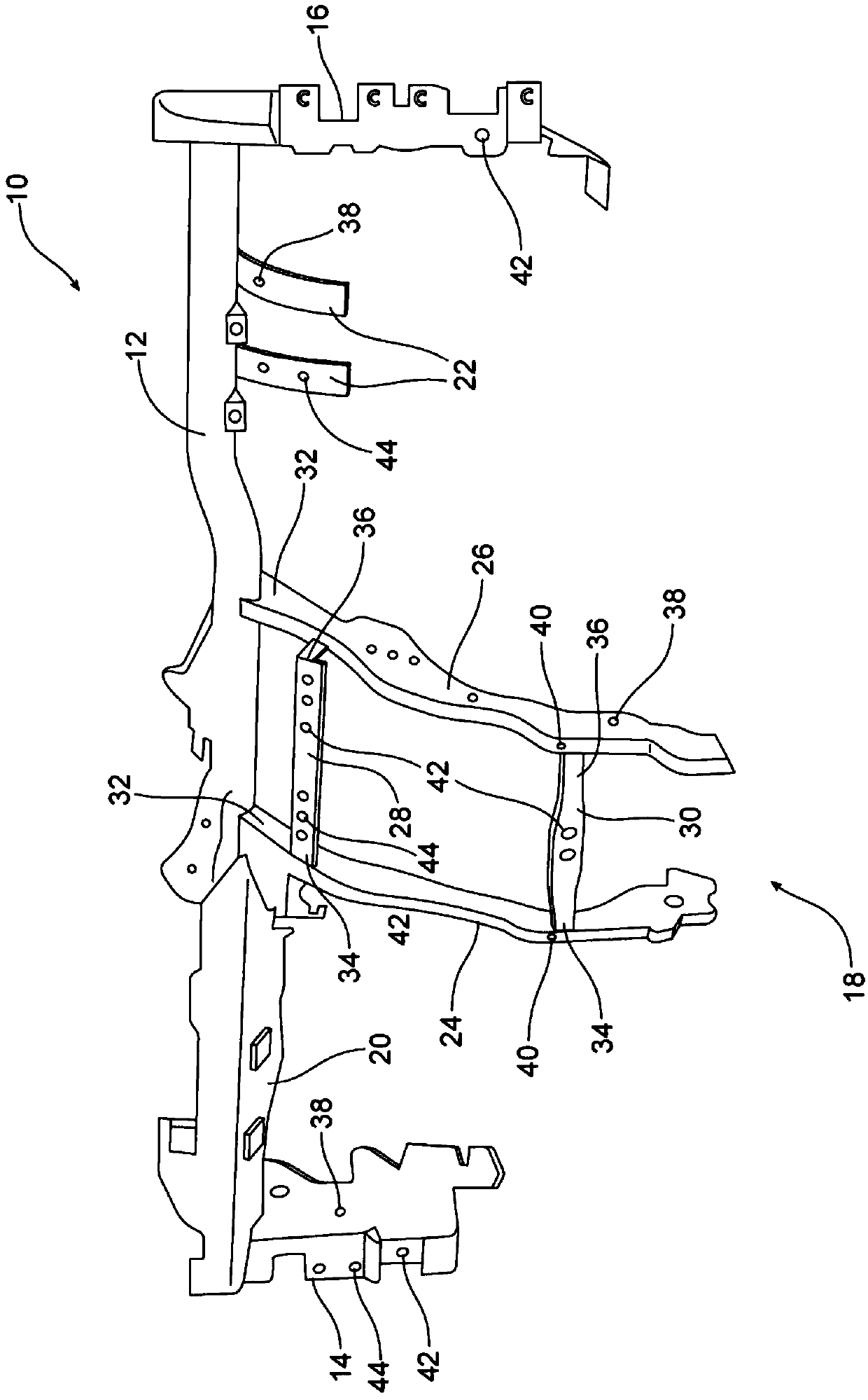

[0017] now refer to figure 1 , which shows a fully assembled vehicle cross member 10 . In the illustrated embodiment, the automotive cross member 10 is assembled from various steel components by welding such as MIG welding or other suitable means. In the illustrated embodiment, the automotive cross member 10 includes: a main structural tube 12; a first shoulder 14 at one end of the main structural tube; a second shoulder 16 at the opposite end of the main structural tube; a center console interface 18 along the middle section of the main structural tube; and steering column bracket 20 on the main structural tube between the first shoulder and the center console interface. Additional support brackets 22 may be provided along the main structural tube 12 to support other features of the motor vehicle, such as a glove box. In the illustrated embodiment, an additional support bracket 22 is provided on the main structural tube between the second shoulder 16 and the center console ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com