Hardware tool box

A toolbox and hardware technology, applied in the manufacture of tools, tool storage devices, etc., can solve the problems of disorderly mixing or stacking of hardware, low space utilization, and insufficient packaging, and achieve high internal space utilization and easy assembly. Simple, easy-to-assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

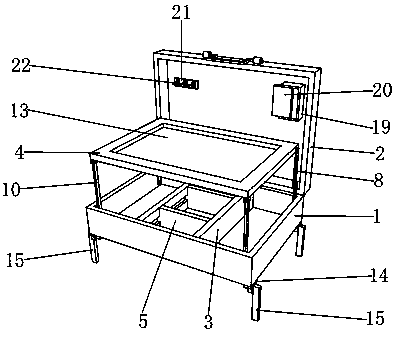

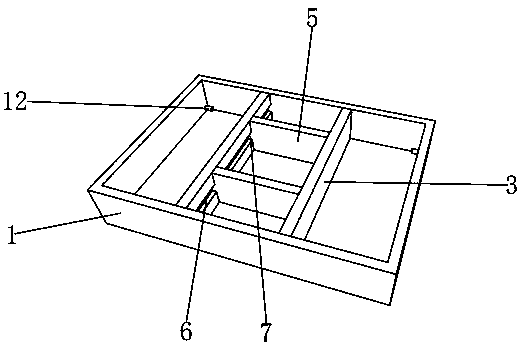

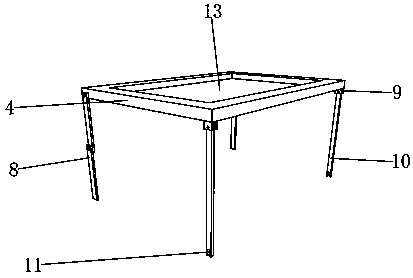

[0020] like Figure 1 to Figure 4 As shown, it is a hardware toolbox of the present invention, comprising a box body 1 and a box cover 2, the box body 1 is movably connected to the box cover 2, and the box body 1 is respectively provided with a partition plate 3 and a supporting plate 4, between the partition plates 3 The baffle plate 5 is slidingly connected, and the partition plate 3 is provided with a chute 6. Both ends of the baffle plate 5 are provided with fixed protrusions 7, the fixed protrusions 7 are located in the chute 6, and the baffle plate 5 is fixed by the fixed protrusion 7. The position is limited in the chute 6, so that the baffle plate 5 cannot be separated from the partition plate 3, and the baffle plate 5 can slide freely between the partition plates 3 to form a variable separation space and improve the space utilization rate. The number of baffles 5 can be added according to the actual situation, and the large space between the baffles 3 can be divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com