Design and manufacture scheme of bearing lanyard

A neck strap and waist belt technology, applied in the field of load-bearing strap design and production scheme, can solve problems such as messiness, cumbersome height adjustment methods, loss of aesthetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

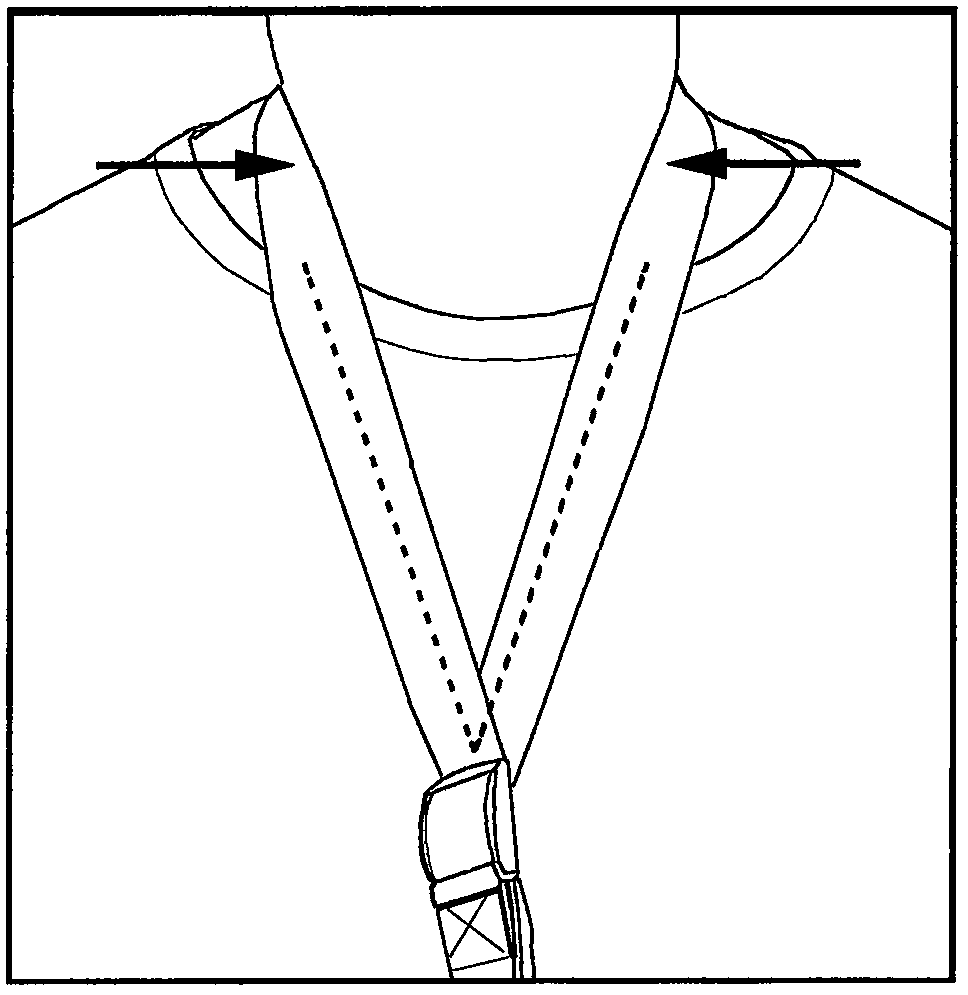

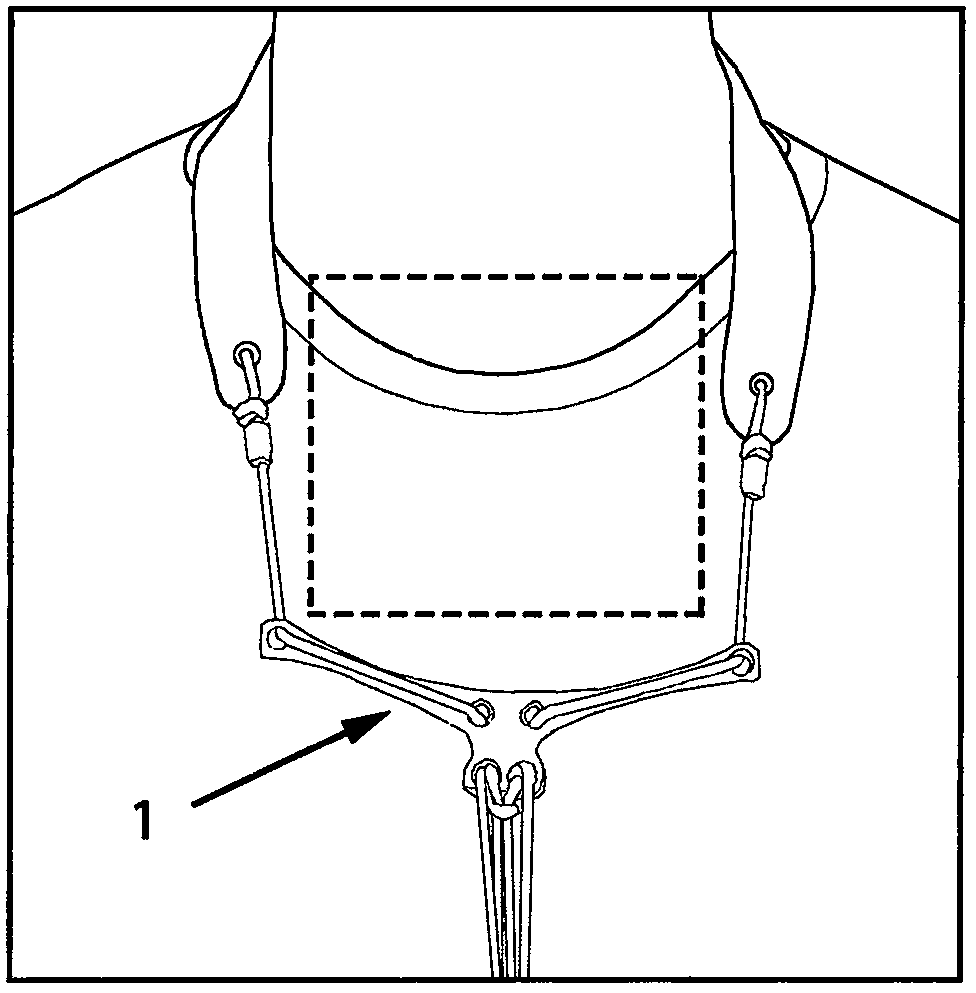

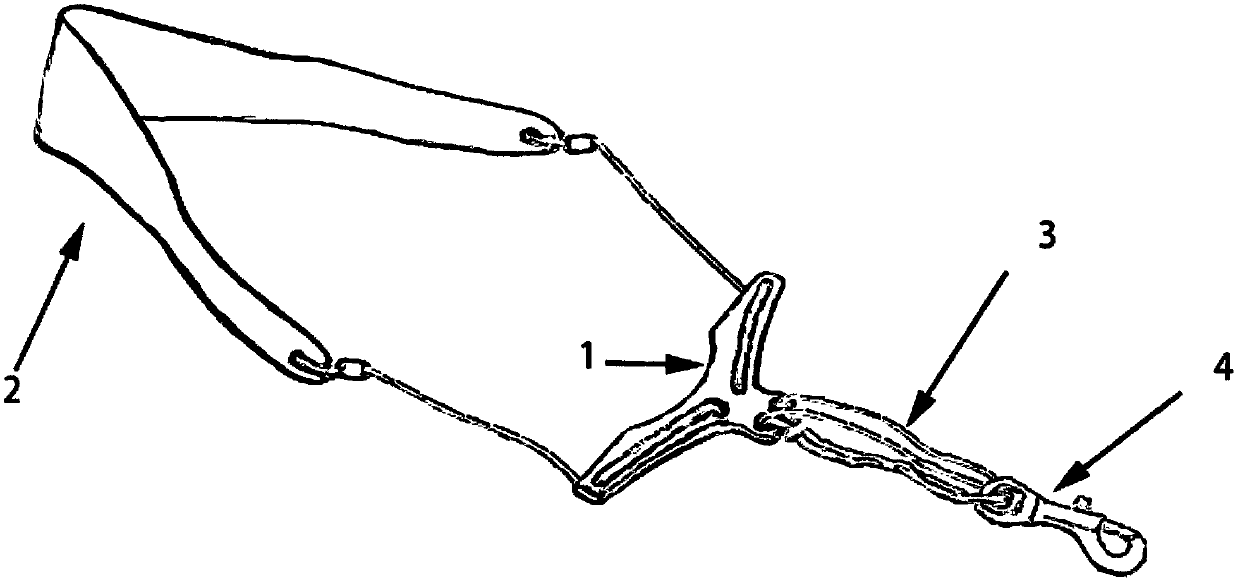

[0023] First, the rigid material 5 of the inner lining of the neckband and the soft material 6 of the inner lining of the neckband are fixed with screws ( Figure 4 , Pic 4-1 ), and then sew the above-mentioned combination material of "hardness and softness" into the outer packaging material "to hide", and bend the neckband according to adults: bending radius R = 70mm, teenagers: bending radius R = 60mm, and make a finished product neck strap.

[0024] Put the lanyard 3 or the belt on the hook, and pass the neck strap 2 to complete the lanyard assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com