Method and a system for calculating coupling power of a single carrier cable freight cableway

A freight cableway and calculation method technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of inaccurate force calculation and low calculation efficiency of bearing cables and traction cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

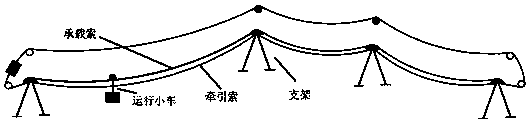

[0118] A method for calculating the coupled dynamics of a single-carrying cable freight cableway, such as figure 1 shown, including:

[0119] Step 1: setting calculation parameters based on the freight cableway;

[0120] Step 2: According to the calculation parameters, calculate the resultant force acting on the bearing cable / traction cable node at the current time step;

[0121] Step 3: Based on the calculation parameters and the resultant force on the nodes of the load cable / traction cable at the current time step, increase the time step according to the preset time increment step, and calculate the action on the load cable / traction cable node at each time step Work together until the preset time period ends.

[0122] Step 1: setting calculation parameters based on the freight cableway;

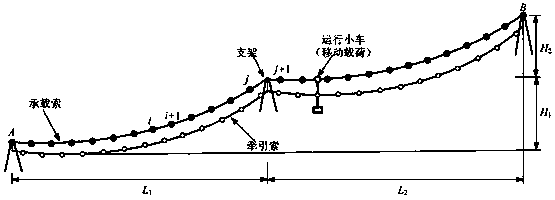

[0123] Such as figure 2 and image 3 shown in image 3 Take the two-stage freight ropeway as an example, the span L of the first stage of the cableway 1 , height difference H 1 , t...

Embodiment 2

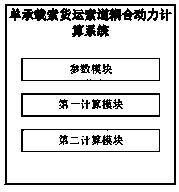

[0251] Based on the same inventive concept, the present invention also provides a coupling dynamic analysis system for a single-carrying freight cableway, such as Figure 12 shown, including

[0252] a parameter module, a first calculation module and a second calculation module;

[0253] Parameter module: used for setting calculation parameters based on the freight cableway;

[0254] The first calculation module: used for judging the nature of the element according to the calculation parameters and the position vectors of the nodes of the load cable and the traction cable at the current moment, and calculating the resultant force of the nodes of the load cable and the traction cable at the current time step;

[0255] The second calculation module: bring the calculation parameters and the resultant force of the node of the current time step bearing cable / traction cable into the pre-established node motion equation, and calculate the next time step bearing cable according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com