Clothes treatment device

A technology for clothes processing devices and moving devices, which is applied to washing devices, other washing machines, household clothes dryers, etc., can solve the problems of loss of control effect and large limitations in installation and use, and achieve simple structure, reliable vibration judgment, and energy saving effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] like Figure 1 to Figure 8 As shown, the clothes treatment device described in this embodiment also includes a second vibration module, the second vibration module is a control rod safety switch, or a vibration sensing module 9, or a detection program, and the detection program includes detecting the current of the clothes treatment device Variation, voltage variation, difference between actual speed and predetermined speed. The first vibration module of the clothes treatment device is connected to the control unit, the second vibration module is connected to the control unit, and the control unit controls the clothes treatment device to stop running and / or send warn.

[0048] The vibration control method of the existing clothes processing device is controlled by the control rod safety switch. Its principle is to install the control rod safety switch on the four corners of the clothing processing device shell 13, and it can only be installed on one corner. , the contr...

Embodiment 2

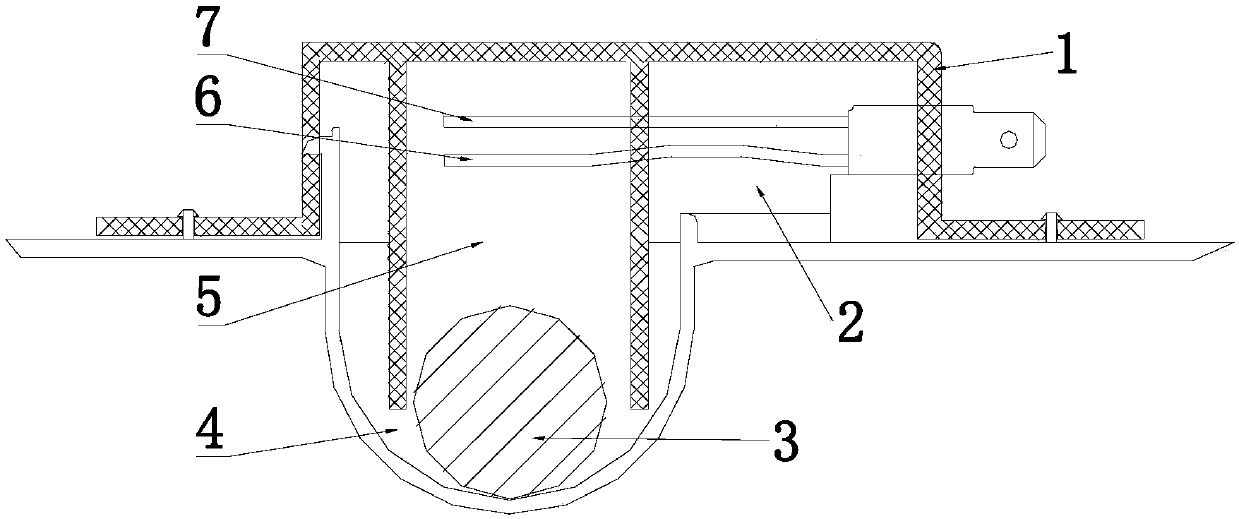

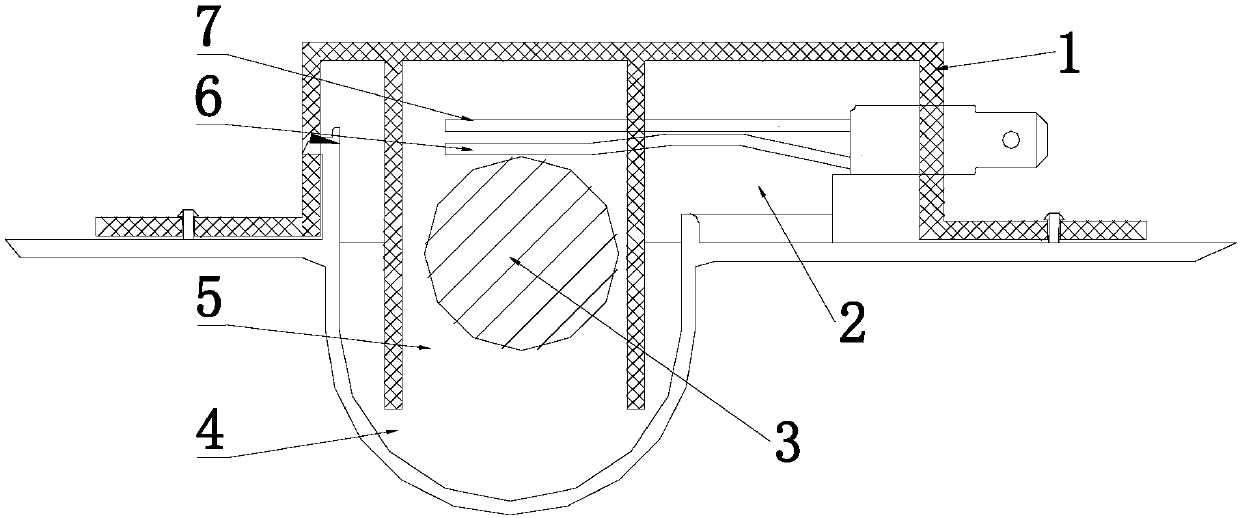

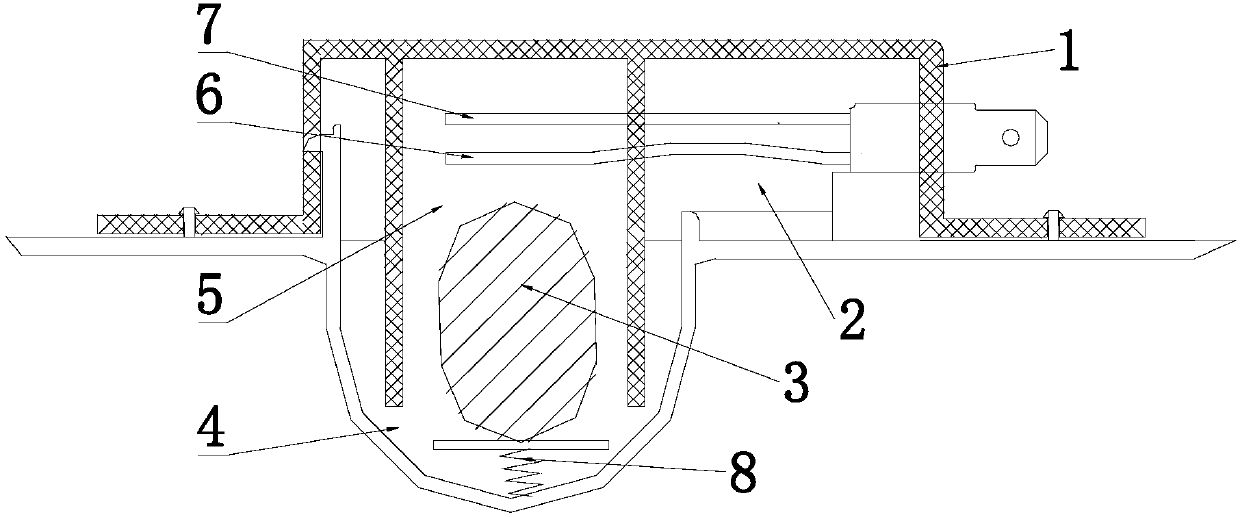

[0053] like Figure 1 to Figure 8 As shown, the laundry treatment device described in this embodiment includes components of the laundry treatment device and a vibration sensing module 9. The vibration sensing module 9 includes a housing 1, at least a part of which is composed of components of the laundry treatment device.

[0054] Specifically, the components of the laundry treatment device in this embodiment can be components on any laundry treatment device such as a box, a base, and a tray, such as Figure 7 and Figure 8 As shown, the vibration sensing module 9 is installed on the base, and at least a part of the housing 1 of the vibration sensing module 9 is composed of components of the laundry processing device. The above components of the laundry treatment device provided with the housing 1 are stationary relative to the laundry treatment device, and will not move within the laundry treatment device due to their own reasons. The casing 1 is composed of components of ...

Embodiment 3

[0058] like Figure 1 to Figure 8 As shown, the clothes processing device described in this embodiment includes a vibration sensing module 9, and the vibration sensing module 9 includes a chamber formed by the casing 1. A limited space is provided in the chamber, and the moving device 3 is movably arranged in the limited space. The device 3 controls the on-off of the vibration sensing module 9 in the limited space. When the laundry treatment device vibrates, the movement device 3 controls the vibration sensing module 9 to be turned on and off according to the vibration degree of the laundry treatment device. The vibration sensing module 9 includes a first state and a second state. The first state is a normally-off state, and the second state is a triggered connection state. The vibration of the movement device 3 triggers the vibration sensing module 9 to be connected. Further, the vibration sensing module 9 triggers communication according to multiple vibrations of the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com