Clothes treatment device

A technology of clothes processing device and exercise device, which is applied to washing devices, other washing machines, household clothes dryers, etc., can solve the problems of wasting space for clothes processing devices, and achieve the effects of simple structure, enhanced exercise activity, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Such as Figure 1 to Figure 8 As shown, the clothes treatment device described in this embodiment also includes a second vibration module, the second vibration module is a control rod safety switch, or a vibration sensing module 9, or a detection program, and the detection program includes detecting the current of the clothes treatment device Variation, voltage variation, difference between actual speed and predetermined speed. The first vibration module of the clothes treatment device is connected to the control unit, the second vibration module is connected to the control unit, and the control unit controls the clothes treatment device to stop running and / or send warn.

[0048] The vibration control method of the existing clothes processing device is controlled by the control rod safety switch. Its principle is to install the control rod safety switch on the four corners of the clothes processing device box 13, and it can only be installed at one corner. On the top,...

Embodiment 2

[0053] Such as Figure 1 to Figure 8 As shown, the laundry treatment device described in this embodiment includes components of the laundry treatment device and a vibration sensing module 9. The vibration sensing module 9 includes a housing 1, at least a part of which is composed of components of the laundry treatment device.

[0054] Specifically, the components of the laundry treatment device can be components on any laundry treatment device such as the box body 13, the bucket assembly 12, the shock absorbing component 11, and the power component 10. At least a part of the housing 1 of the vibration sensing module 9 is composed of component composition. Further, the components of the laundry treatment device provided with the housing 1 are stationary relative to the laundry treatment device. The housing 1 is composed of the components of the laundry treatment device. The housing is provided with a fixing part, and the second housing is provided with a mounting part matched ...

Embodiment 3

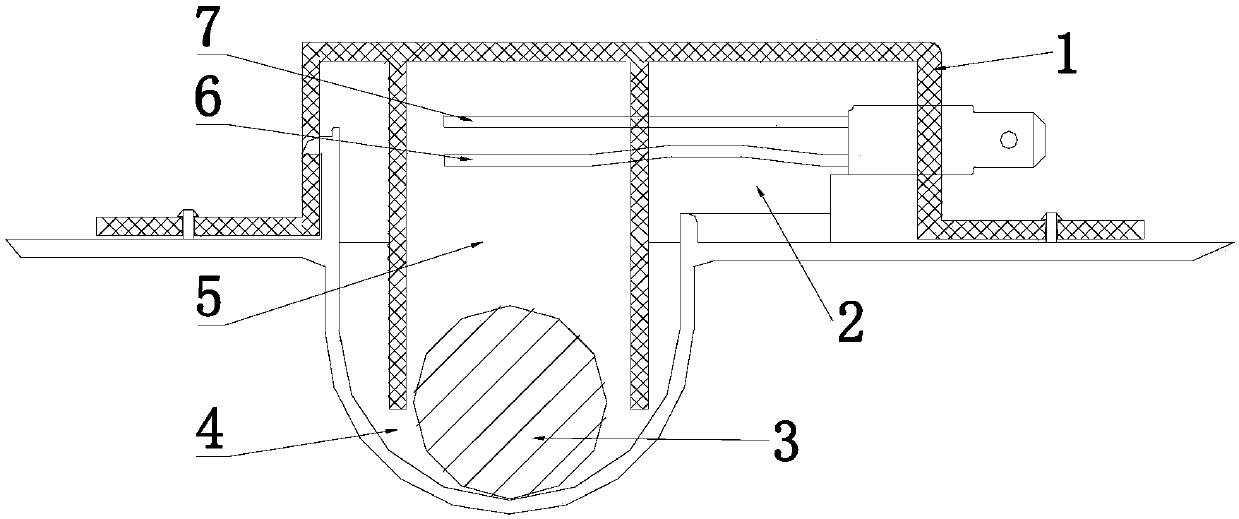

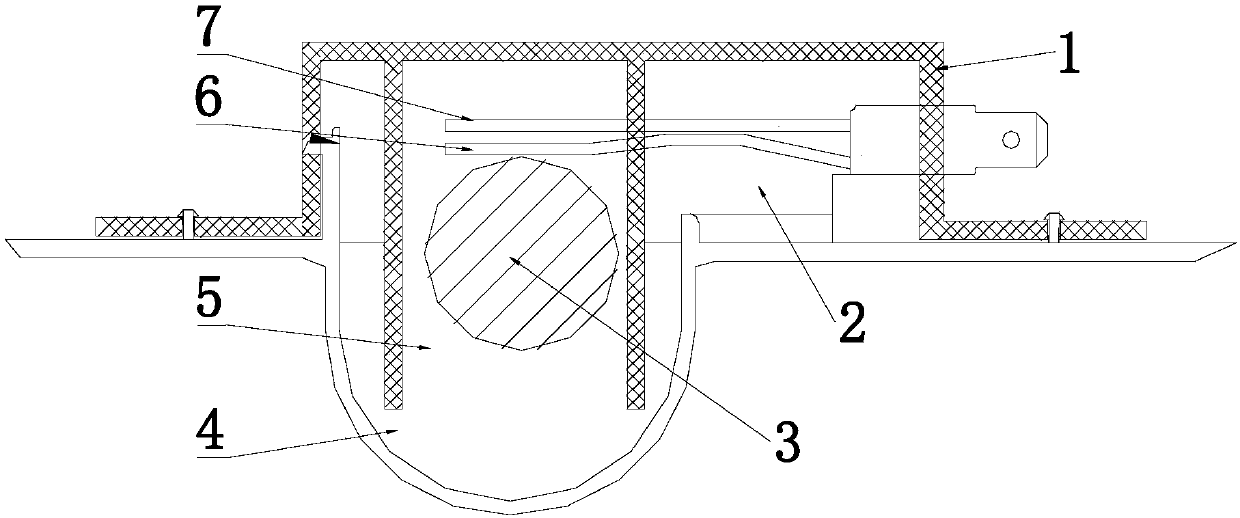

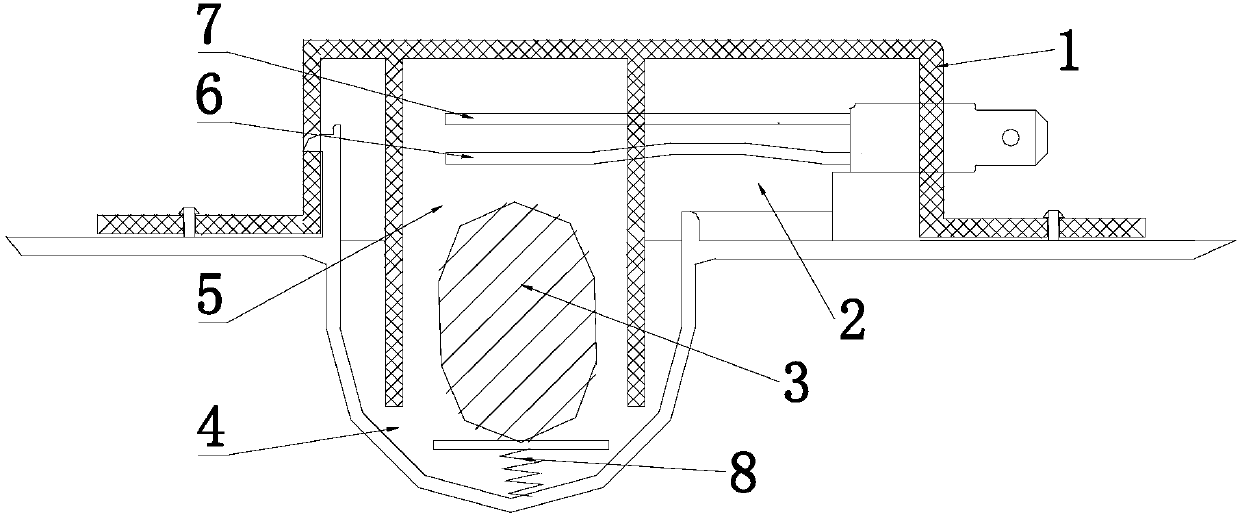

[0058] Such as Figure 1 to Figure 8 As shown, the clothes processing device described in this embodiment includes a vibration sensing module 9, and the vibration sensing module 9 includes a chamber formed by the casing 1. A limited space is provided in the chamber, and the moving device 3 is movably arranged in the limited space. The movement of the device 3 in the limited space controls the on-off of the vibration sensing module 9 . When the laundry treatment device vibrates, the movement device 3 controls the vibration sensing module 9 to be turned on and off according to the vibration degree of the laundry treatment device. The vibration sensing module 9 includes a first state and a second state. The first state is a normally-off state, and the second state is a triggered connection state. The vibration of the movement device 3 triggers the vibration sensing module 9 to be connected. Further, the vibration sensing module 9 triggers communication multiple times according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com