A horizontal lifting device for an automatic locking iron bucket

A technology of lifting device and iron bucket, which is applied in the direction of safety device, transportation and packaging, load hanging components, etc., can solve the problems of prone to falling accidents, and achieve the effect of preventing easy falling off and stable unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

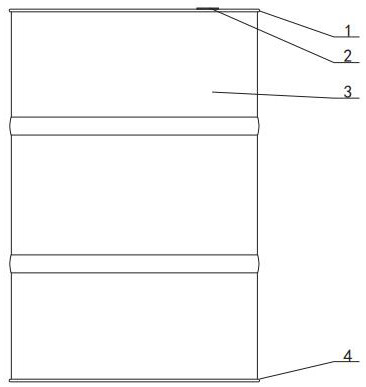

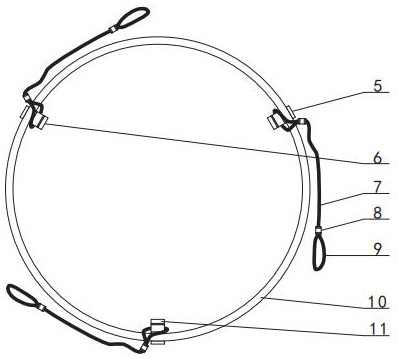

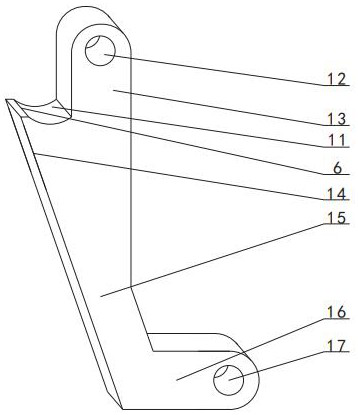

[0025] combined with Figures 2 to 6 The horizontal lifting device of the automatic locking iron bucket includes a collar 10, a pin shaft, a lock block 5 and a sling 7, and three through holes in a triangular distribution are arranged between the inner surface and the outer edge surface of the collar 10 20. The horizontal blocks 16 at the bottom of the three locking blocks 5 are respectively hinged to the through holes 20 of the collar 10 through pin shafts. The upper inner ends of the horizontal blocks 16 of the three locking blocks 5 are provided with an inclined bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com