Lifting appliance for metal bucket

A technology of iron buckets and slings, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as prone to falling accidents, and achieve the effect of preventing easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

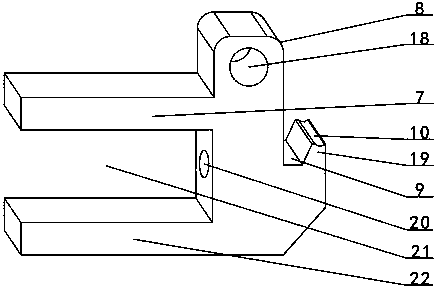

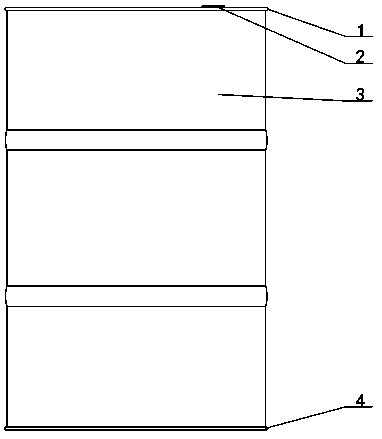

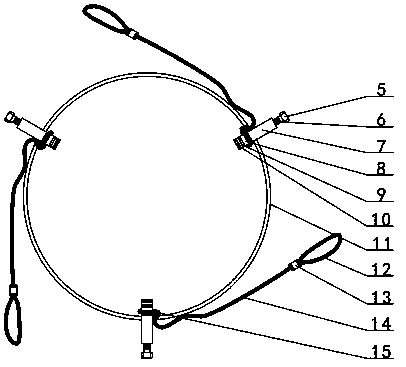

[0030] combined with Figures 2 to 6 The sling of the tin bucket includes a steel ring 11, a screw 5, a top block and a sling 14, and the steel ring 11 is provided with three screw holes 17 in a triangular distribution, on the outer surfaces of the three top blocks up and down. An upper clamping rod 7 and a lower clamping rod 22 are respectively provided, and the clamping groove 21 is formed between the upper clamping rod 7 and the lower clamping rod 22. Between the rod 7 and the lower clamping rod 22, the slots 21 on the outer sides of the three top blocks are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com