Decorative reflective coating and preparation method thereof

A reflective paint and decorative technology, applied in the field of paint, can solve the problems of inability to achieve, the reflective paint cannot be used normally, and the adhesion of the paint cannot be realized, and the effect of improving the adhesion performance can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A decorative reflective paint, the raw materials of the reflective agent include by weight: 25 parts of phenolic resin, 15 parts of polyurethane, 4 parts of polyethylene glycol dicarboxylic acid, 4 parts of urea heterocyclic adhesion enhancer, 7 parts of polyethylene 2 parts, 2 parts of reflective agent, 4 parts of glass beads, 2 parts of film-forming agent, 2 parts of fluorescent powder, 2 parts of defoamer and 4 parts of mineral essential oil solvent, and the raw materials of protective agent include: 45 parts of silicone oil , 25 parts of fatty acid amide and 15 parts of dipropylenetriamine, the urea heterocyclic adhesion enhancer is the wet adhesion monomer of double bond urea heterocyclic compound containing double bond V-70M, and the reflective agent is silicon dioxide, calcium oxide, The composition of titanium dioxide and barium oxide, the film forming agent is nitrocellulose, and the defoaming agent is polyoxyethylene polyoxypropanolamine ether.

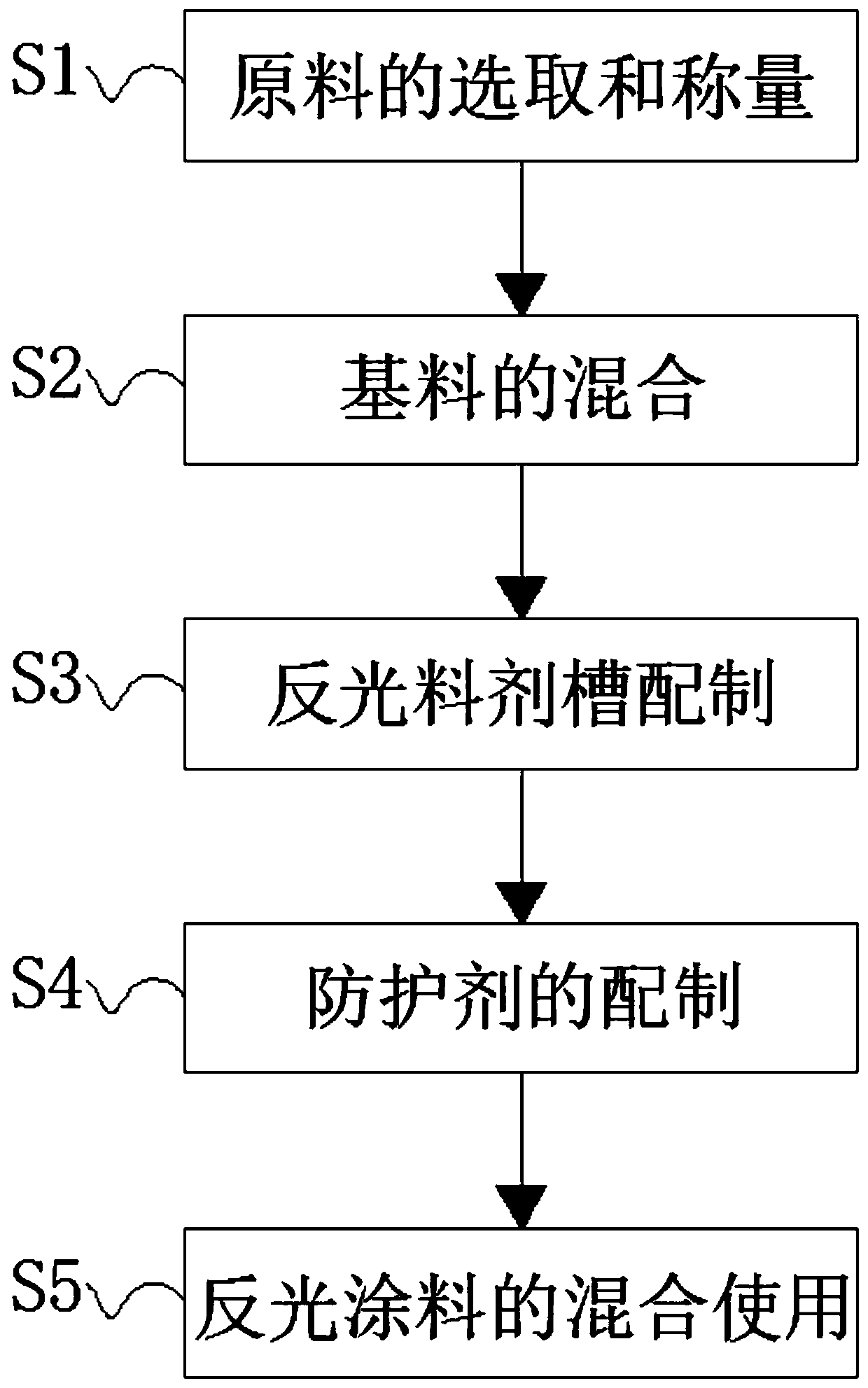

[0027] A prep...

Embodiment 2

[0034] A decorative reflective paint, the raw materials of the reflective agent include by weight: 20 parts of phenolic resin, 10 parts of polyurethane, 3 parts of polyethylene glycol dicarboxylic acid, 3 parts of urea heterocyclic adhesion enhancer, 5 parts of polyethylene 1 part, 1 part of reflective agent, 3 parts of glass beads, 1 part of film-forming agent, 1 part of fluorescent powder, 1 part of defoamer and 3 parts of mineral essential oil solvent, and the raw materials of protective agent include: 40 parts of silicone oil , 20 parts of fatty acid amide and 10 parts of dipropylenetriamine, the urea heterocyclic adhesion enhancer is a model V-70M containing double bond urea heterocyclic compound wet adhesion monomer, the reflective agent is silicon dioxide, and the film forming agent It is nitrocellulose, and the defoamer is polydimethylsiloxane.

[0035] A preparation method for a decorative reflective paint, specifically comprising the following steps:

[0036] S1. Se...

Embodiment 3

[0042] A decorative reflective paint, the raw materials of the reflective agent include by weight: 30 parts of phenolic resin, 20 parts of polyurethane, 5 parts of polyethylene glycol dicarboxylic acid, 5 parts of urea heterocyclic adhesion enhancer, 10 parts of polyethylene 3 parts, 3 parts of reflective agent, 5 parts of glass beads, 3 parts of film-forming agent, 3 parts of fluorescent powder, 3 parts of defoamer and 5 parts of mineral essential oil solvent, and the raw materials of protective agent include: 50 parts of silicone oil , 30 parts of fatty acid amide and 20 parts of dipropylenetriamine, the urea heterocyclic adhesion enhancer is the wet adhesion monomer of double bond urea heterocyclic compound containing double bond V-70M, the reflective agent is barium oxide, and the film forming agent is Nitrocellulose, and the defoamer is polyoxyethylene polyoxypropanolamine ether.

[0043] A preparation method for a decorative reflective paint, specifically comprising the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com