Sea mine fuze test method

A fuze test and mine technology, applied in fuzes, weapon accessories, offensive equipment, etc., can solve problems such as dangerous, laborious, and unreliable seawater operations, reduce test workload, avoid failure or distortion of data collection, and improve reliability. sexual effect

Active Publication Date: 2019-06-07

CHONGQING QIANWEI SCI & TECH GRP

View PDF10 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the existing sea mine fuze regional test method has the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

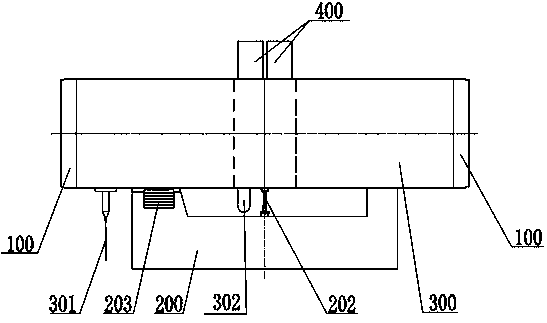

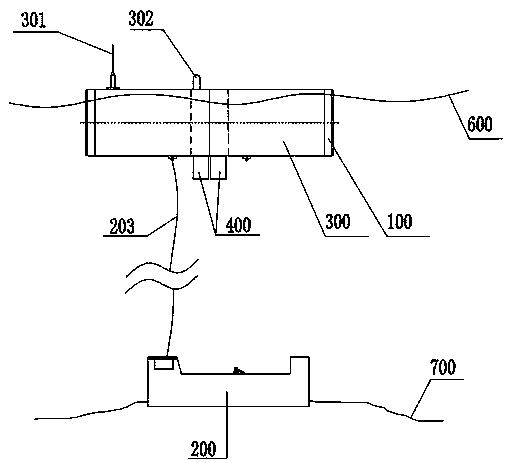

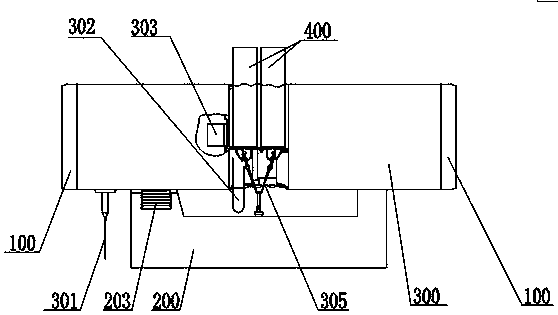

The invention discloses a sea mine fuze test method which is characterized by comprising the following steps: obtaining a mine body for test and mounting a data acquisition module in the mine body fortest for acquiring and recording fuze action information, wherein a controllable mechanical claw is fixedly mounted out of the mine body for test; connecting the mine body for test to an anchor bodywith negative buoyancy through the controllable mechanical claw; hoisting the mine body for test and the anchor body underwater; passing a target object through the periphery of the fuze to trigger action of the fuze, and recording fuze action information by the data acquisition module; acting the controllable mechanical arm to unlock, wherein the mine body for test is separated from the anchor body and emerges from the water under the action of positive buoyancy to be recovered; and reading the fuze action information from a data recorder of the recovered mine body for test and finishing a test. The sea mine fuze test method disclosed by the invention has the advantages of being more labor-saving, safer and more reliable to test.

Description

technical field [0001] The invention belongs to the field of mine fuzes, in particular to a test method for mine fuzes. Background technique [0002] The Japanese Patent No. 7-89040 discloses a "stationary mine", which is detonated by a "mine fuze" set in it, and the structure and control method of the "mine fuze" in its structure Relatively simple, easily passivated by intruders. [0003] The patent with the notification number CN1008944B discloses an "improved trigger device for submarine mines". The "improved trigger device for submarine mines" is a kind of "mine fuze". Effectively prevent "inertization of detonation" and have better reliability. [0004] "Mine Fuze" needs to be tested before official use to verify and ensure reliability. At present, the regional test method of the mine fuze is to install the fuze in the mine body filled with inert substances (which will not explode), and recover the fuze (action) response data through cable connection. After the test...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F42C21/00

Inventor 何兴友徐猛宗方勇夏庆升陈国邓义林

Owner CHONGQING QIANWEI SCI & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com