Intelligent test platform for anti-clogging performance of drip irrigation belt

A test platform, anti-clogging technology, applied in the direction of measuring capacity, measuring device, liquid/fluid solid measurement, etc., to achieve the effect of saving manpower and material resources, reducing test workload, and eliminating manual control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

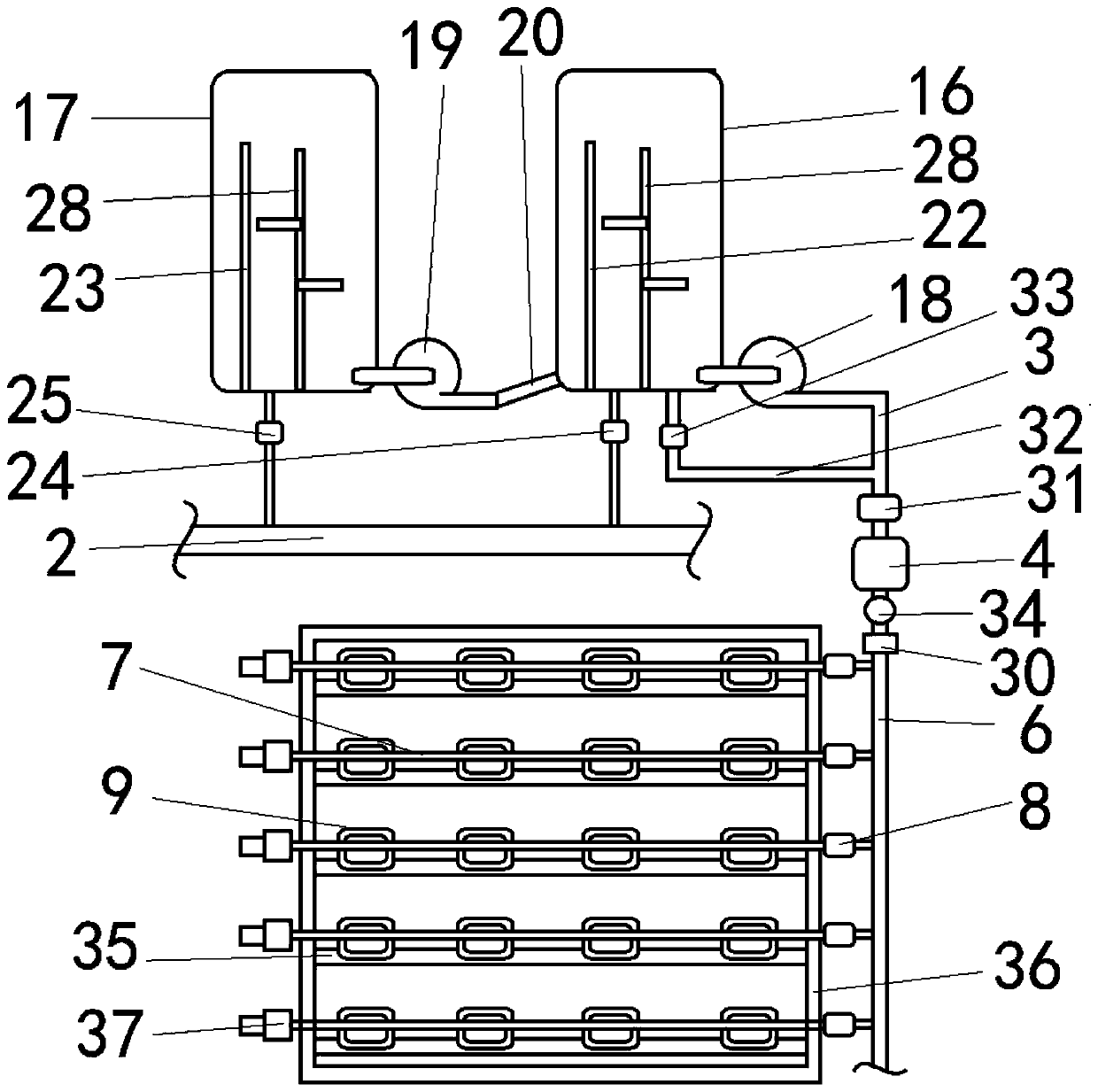

[0017] according to figure 1 , an intelligent test platform for drip irrigation belt anti-clogging performance, which mainly includes: a first water intake system, the water inlet end of the first water intake system communicates with the tap water pipe 2, and the outlet end is connected with a water supply main pipe 3, and the water supply main pipe 3. A fertilizer applicator 4 is connected in series; the pipe network consists of several water supply branch pipes 6 connected to the end of the main water supply pipe 3 away from the head water intake system, and several water supply branch pipes 6 communicated with the water supply branch pipes 6 through capillary solenoid valves 8. Capillary 7 constitutes; flow collector 9, described flow collector 9 is a plurality of settings, and is distributed and arranged below each described capillary 7; Slave computer, described lower computer and described flow collector 9 and described capillary The solenoid valve 8 is electrically con...

Embodiment 2

[0020] The head water intake system includes a water supply bucket 16 and a water replenishment bucket 17; the outlet of the water supply bucket 16 is communicated with a water supply pump 18, and the water outlet of the water supply pump 18 is communicated with the water supply branch pipe 6; The water outlet is in communication with the water inlet of the replenishment water pump 19 , and the outlet of the replenishment water pump 19 is communicated with the replenishment end of the water supply barrel 16 through a water replenishment pipe 20 . It also includes a water replenishment controller, and a first water level sensor 22 and a second water level sensor 23 respectively arranged in the water supply barrel 16 and the water replenishment barrel 17, and the water supply barrel 16 and the water replenishment barrel 17 pass through the first Solenoid valve 24 and second solenoid valve 25 communicate with described tap water pipe 2; Described first water level sensor 22, descr...

Embodiment 3

[0023] The water supply bucket 16 and the water replenishment bucket 17 are respectively provided with a stirring device 28 for stirring the water source during the muddy water test.

[0024] In the above arrangement, the stirring device 28 is used for stirring the water source during the muddy water test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com