An accumulation controller for suspension trolley of filter plate production line and its control method

A technology for hanging trolleys and production lines, applied in conveyor control devices, conveyors, mechanical conveyors, etc., can solve the problems of multiple suspended trolleys colliding, lack of automatic obstacle avoidance functions, etc., to avoid collision accidents and reduce labor. Labor-intensive, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

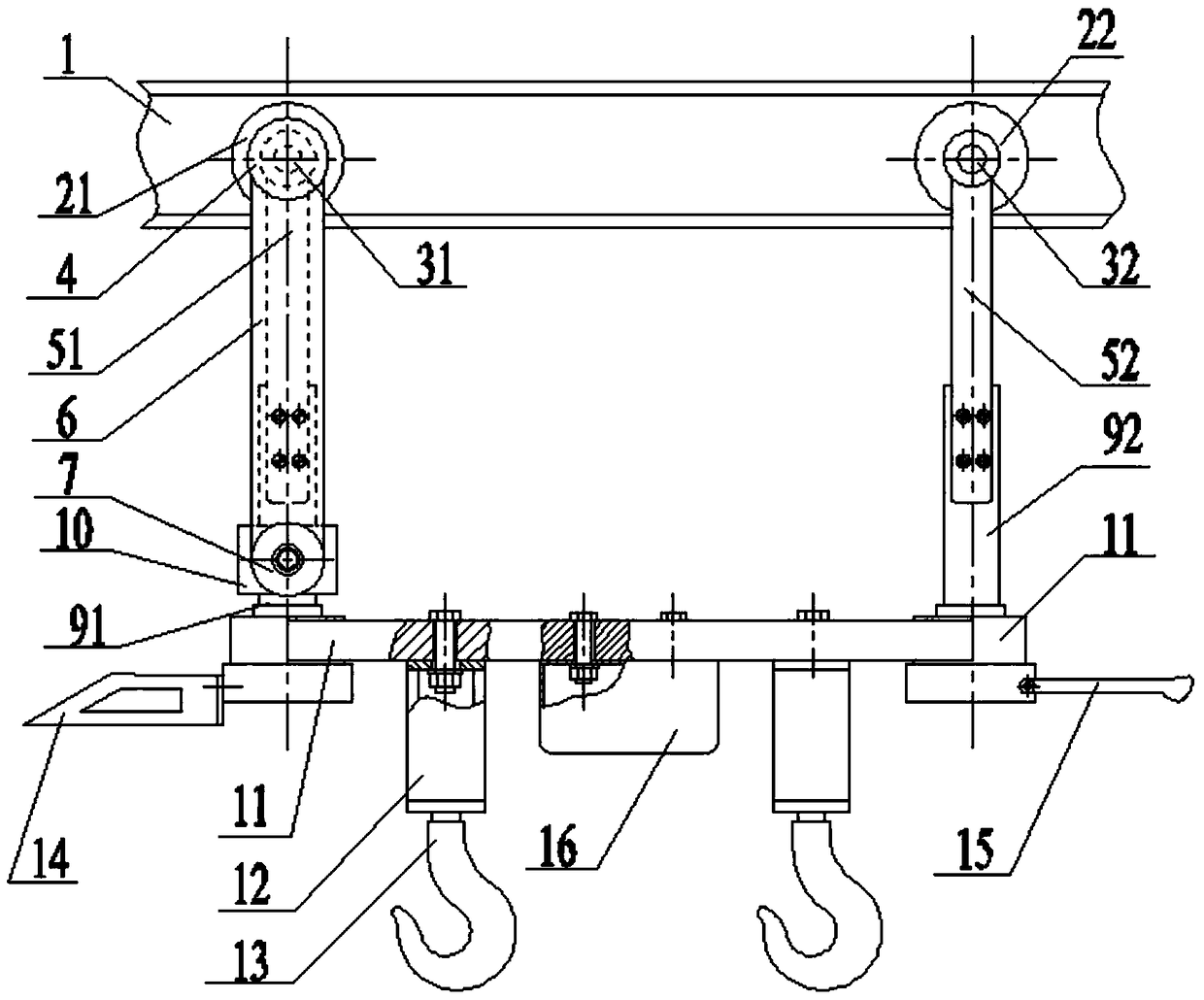

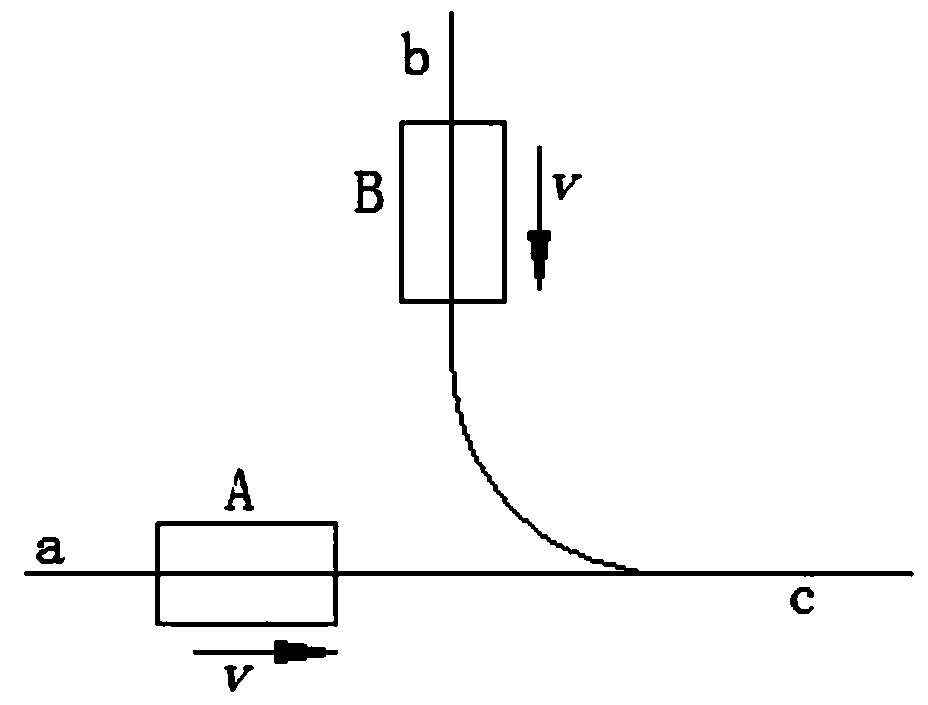

[0075] The distance that the released suspension trolley runs from the start to the position where the tail leaves the baffle is the body length of the suspension trolley, L=0.8m; for the running speed of the suspension trolley, according to the specific design, its running speed is 0.257m / s, Bring the above data into formula 1-1, and calculate the waiting time t for the accumulation controller to rotate 1 = 3.12s.

[0076] In order to ensure that the suspended trolley does not collide during operation, according to the specific design, the total length b of the push claw and the control claw can be set to 0.3m, and the length a of the push claw can be set to 0.3m; for the delayed start time of the suspended trolley, in order It does not affect the existing production efficiency, and in order not to let the accumulation controller rotate too fast, it is set to 1s. Bring the above data into the formula 1-2, and calculate the rotation time t for the accumulation controller to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com