Rubber floor automatic preparation system and preparation method

A technology of rubber floor and preparation system, which is applied to flat products, applications, household appliances, etc., can solve problems such as low efficiency and difficult to guarantee preparation accuracy, achieve the improvement of automation, reduce manual operation control, and avoid difficult to guarantee preparation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The embodiment of the present application discloses an automatic rubber floor preparation system and a preparation method, which are used to solve the technical problems that each process of the existing rubber floor preparation process is manually operated and controlled, and the preparation accuracy is difficult to guarantee and the efficiency is low.

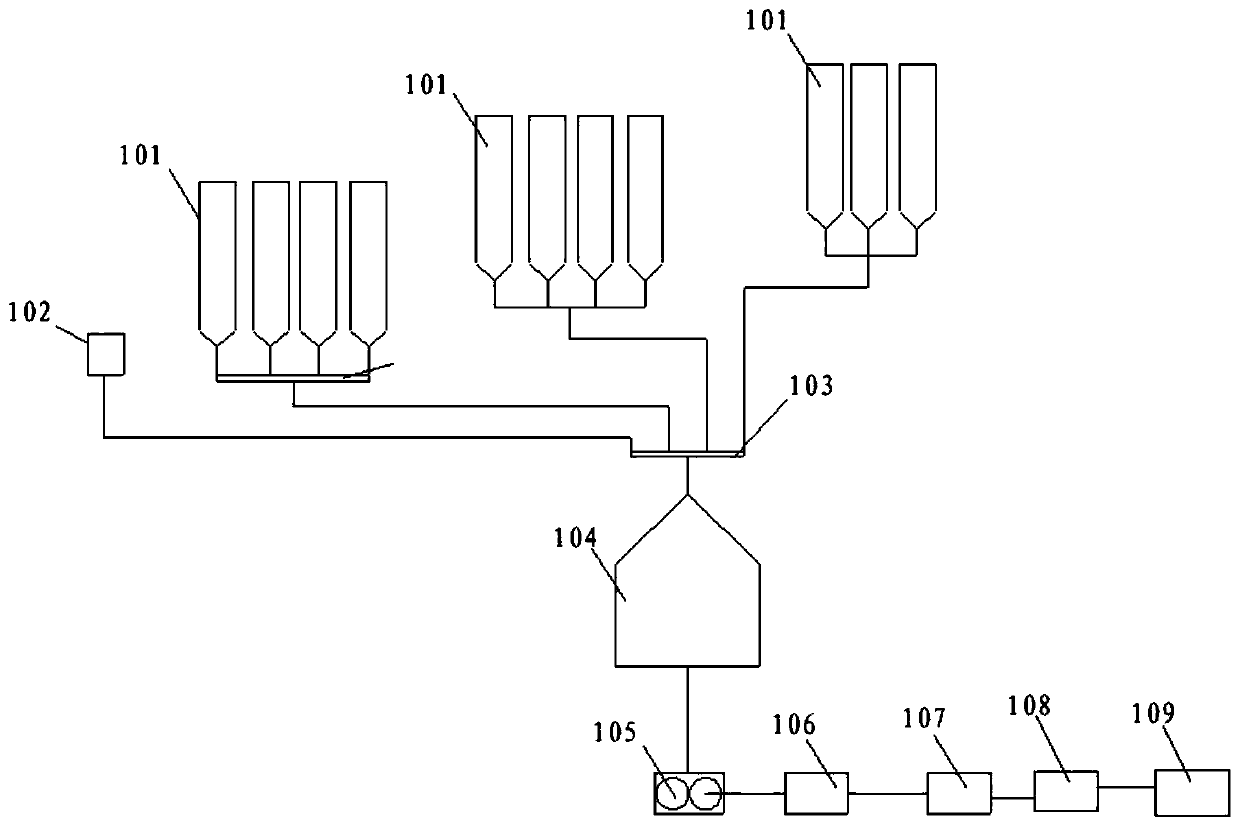

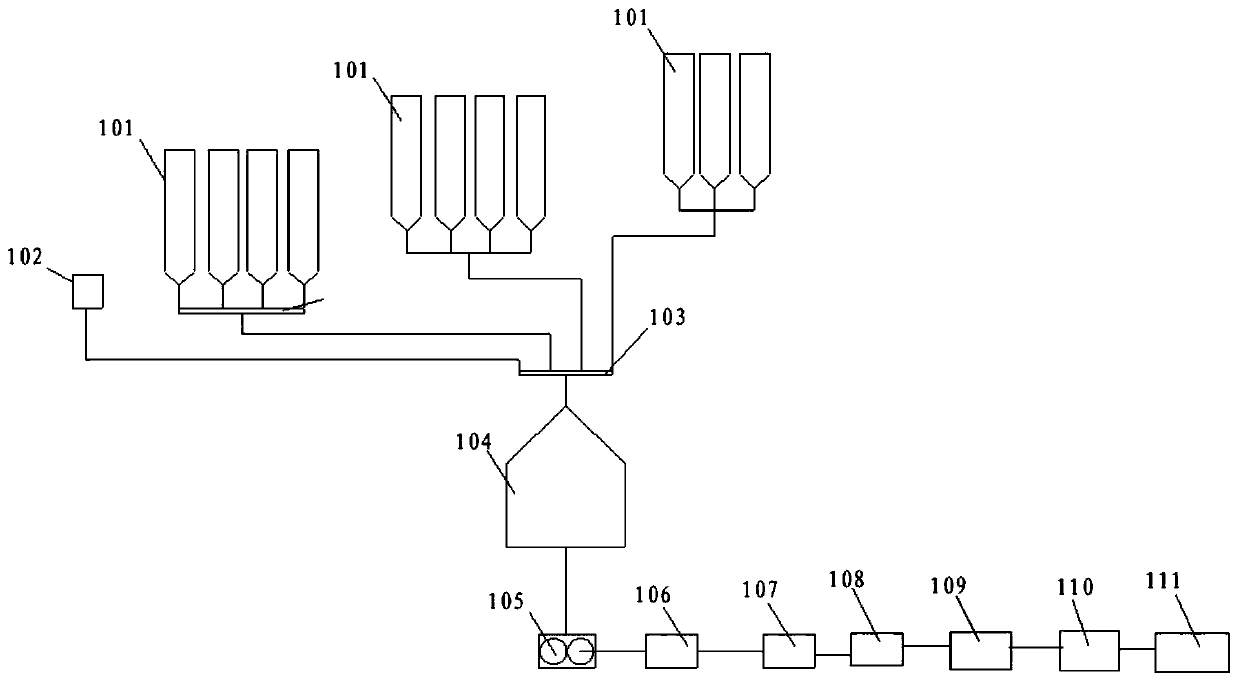

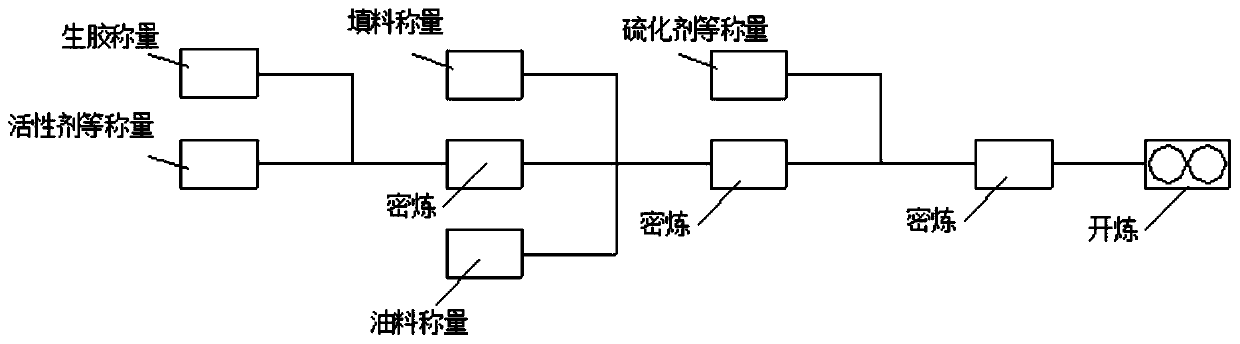

[0054] see figure 1, the present application provides an embodiment of an automatic rubber floor preparation system. The rubber floor automatic preparation system provided in the embodiment of the present application includes: a loading table 103, an internal mixer 104, an open mixer 105, a cooling device 106, Calender 107, semi-finished workbench and flat vulcanizer 109;

[0055] The loading platform 103 is provided with a weighing machine 102 and a material storage tank. The material storage tank is provided with several tank bodies 101 for storing rubber mixing materials. The weighing machine 102 is used for weighin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com