Tension measuring device and tensiometer auxiliary clamping tool thereof

A technology of measuring device and clamping tool, applied in tension measurement and other directions, which can solve the problems of easy shaking of operators and inaccurate tension measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

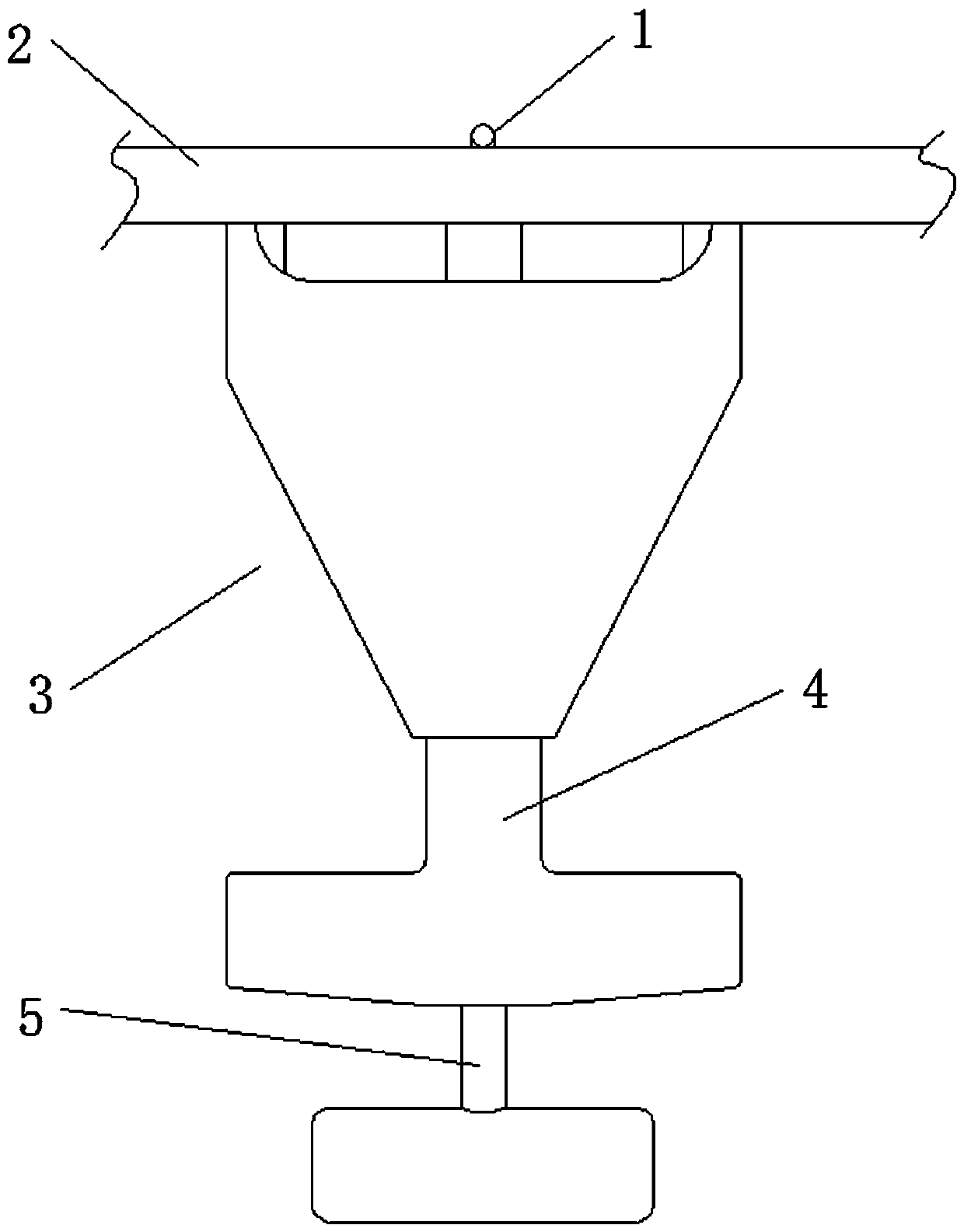

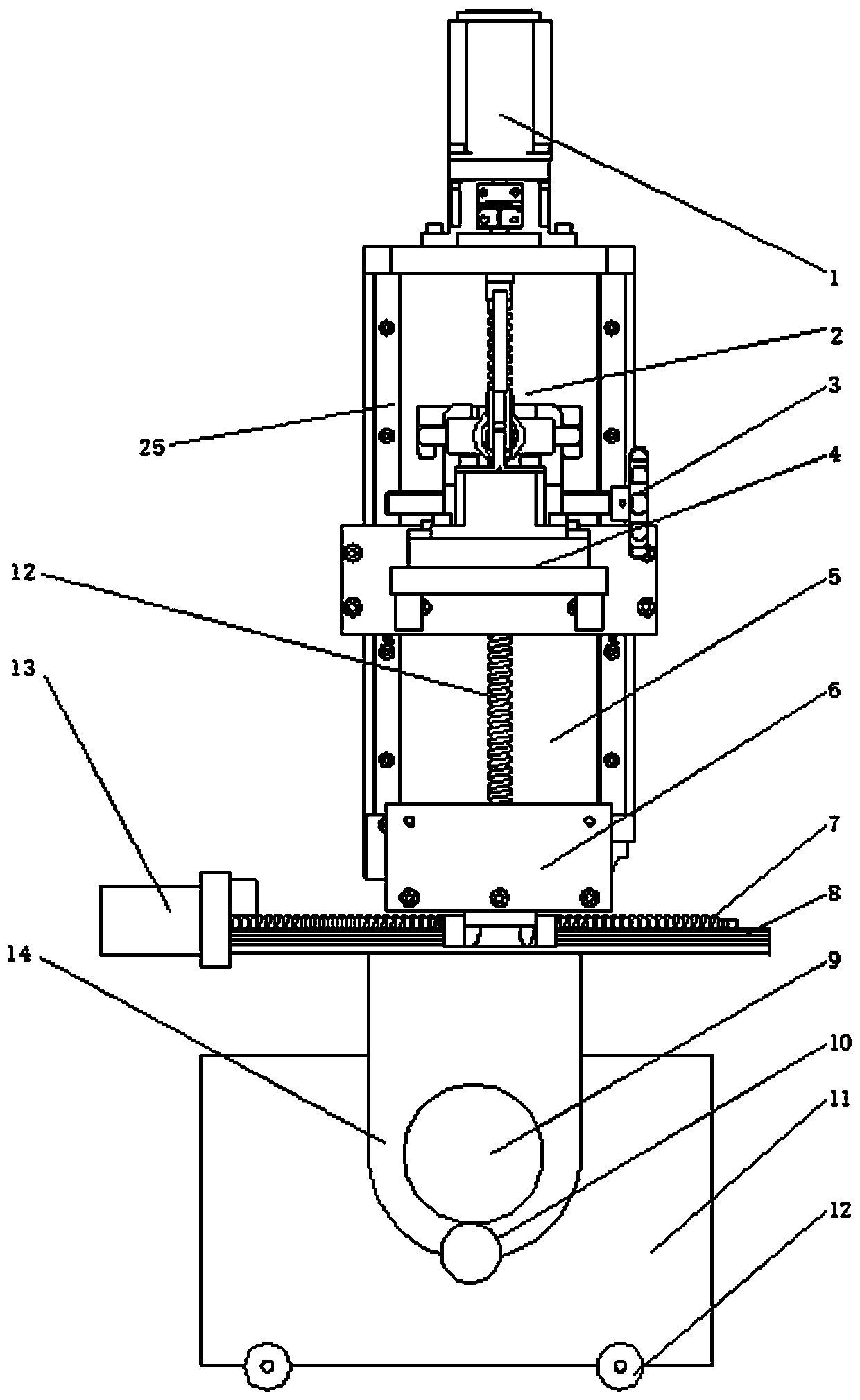

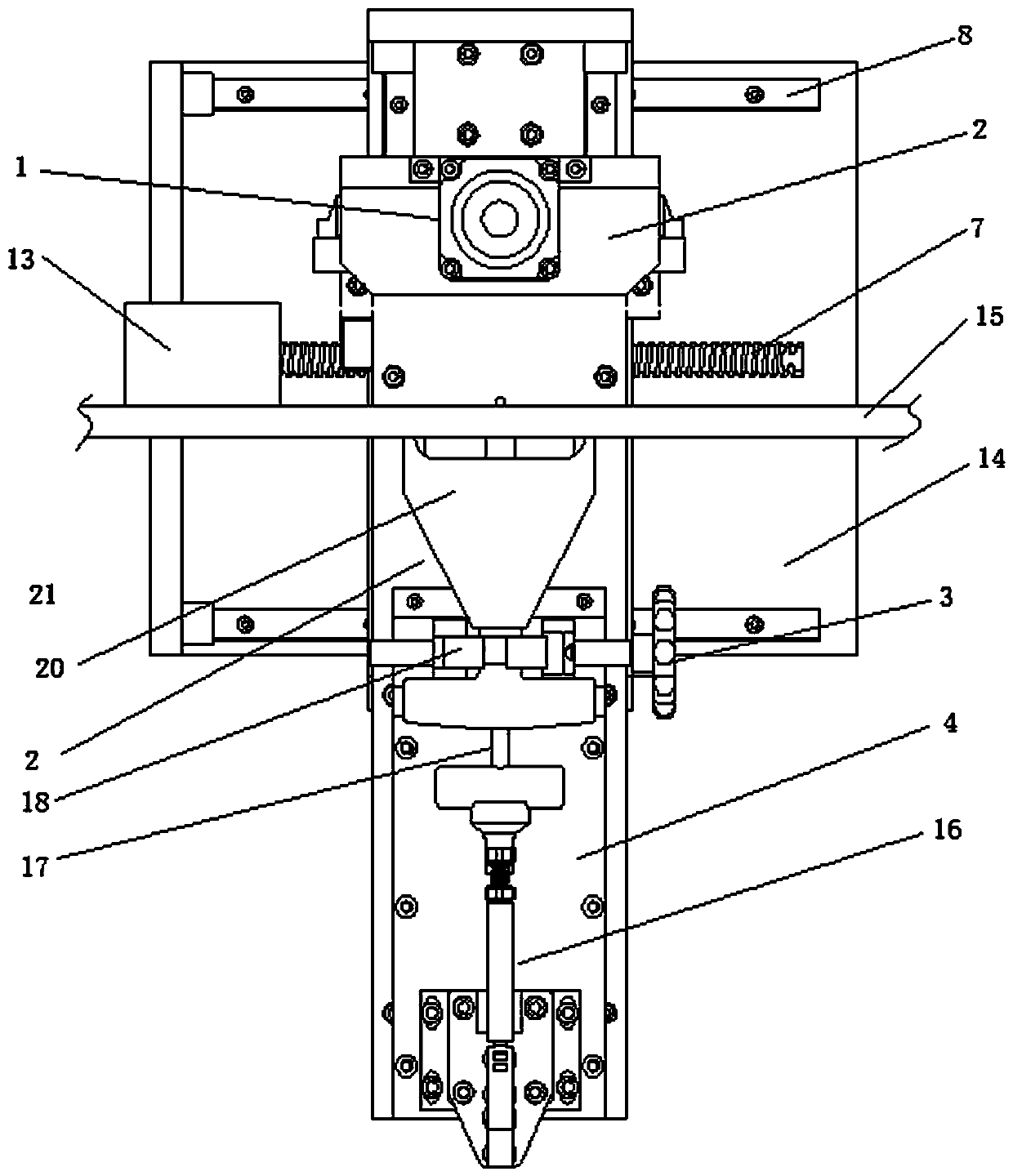

[0023] An example of a tension measuring device is Figure 2~6 Shown: comprise tensiometer 2 and tensiometer auxiliary clamping tool, wherein tensiometer belongs to prior art, and it comprises tensiometer housing 20 and guiding movement is assembled on the measuring bar 17 on the tensiometer housing, measuring bar 17 and tension A measuring rod return spring is arranged between the gauge housings 20, and a hook structure 21 for hooking a corresponding piece to be measured is arranged at the front end of the tensiometer. The innovation of the present invention lies in the design of an auxiliary tensiometer clamping tool capable of clamping and fixing the tension gauge.

[0024] The tensiometer auxiliary clamping tool includes a device seat 11. The bottom of the device seat 11 is provided with a walking wheel 12. The device seat is rotatably equipped with a measuring bracket 14 whose rotation axis extends along the front and rear directions. Support drive mechanism, in the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com