Feeding device for aquaculture

A technology of aquaculture and mounting seat, which is applied in the field of feeders, can solve the problems of concentrated throwing feed, high labor intensity, and short distance of throwing feed, and achieve the effects of preventing competition, reducing labor intensity, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

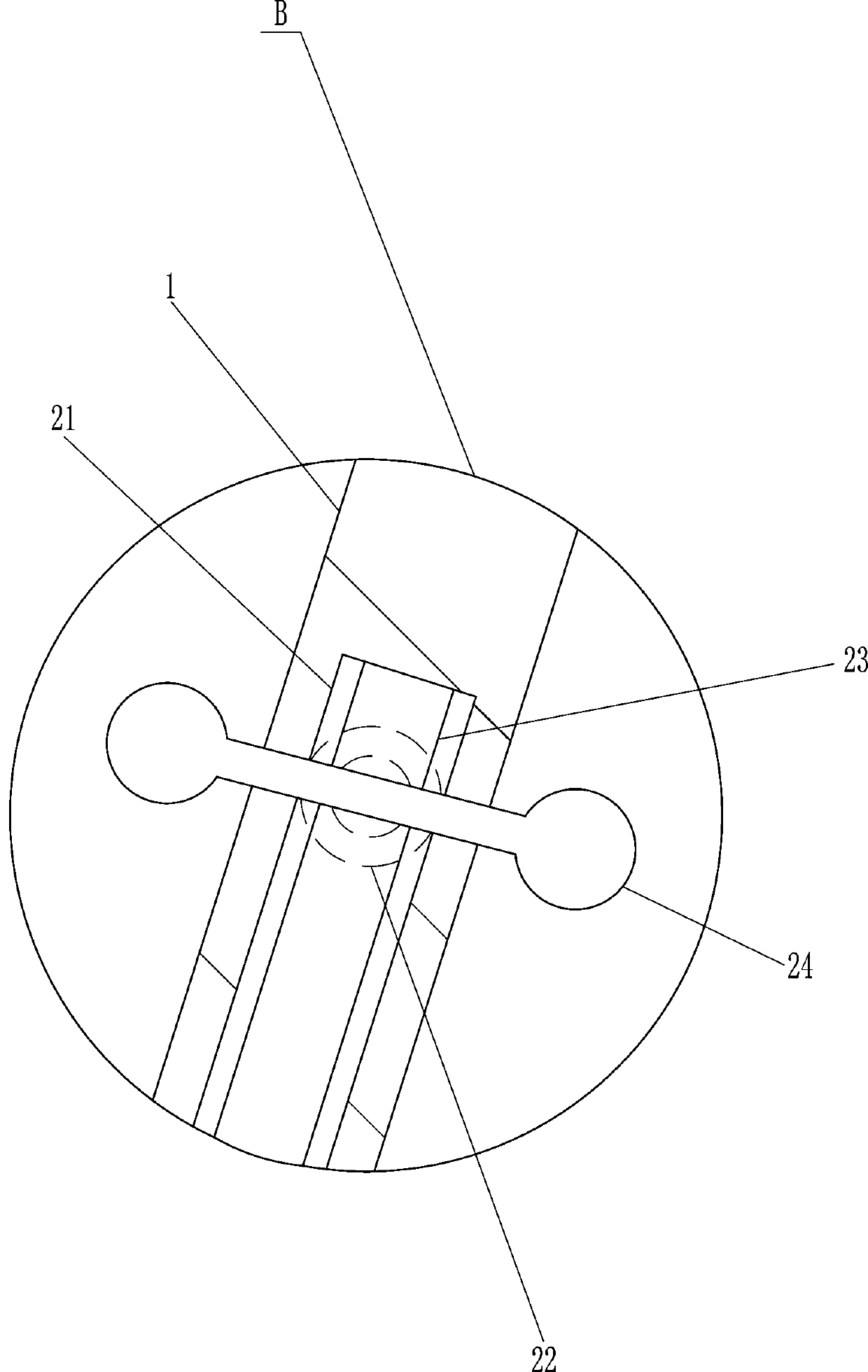

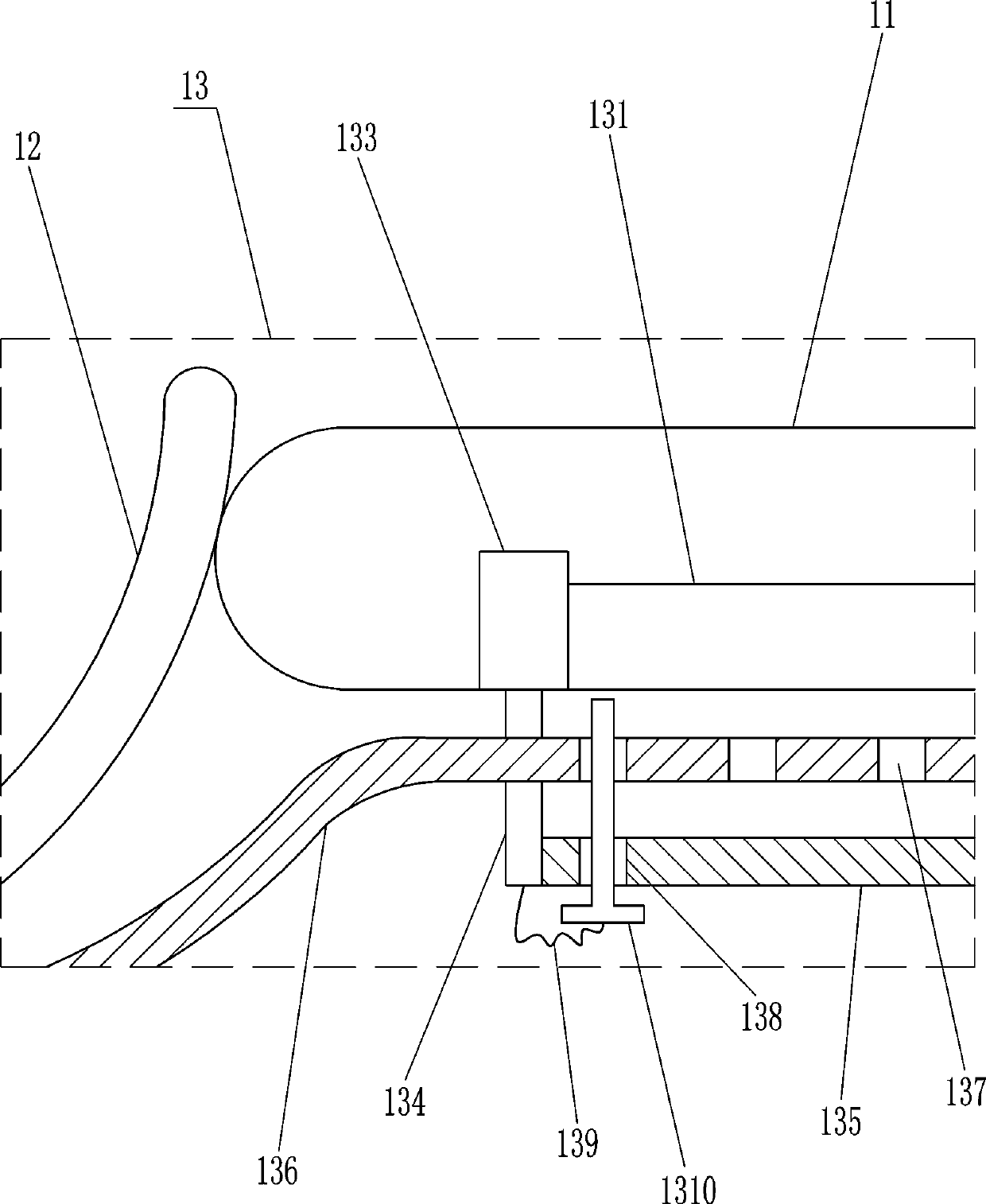

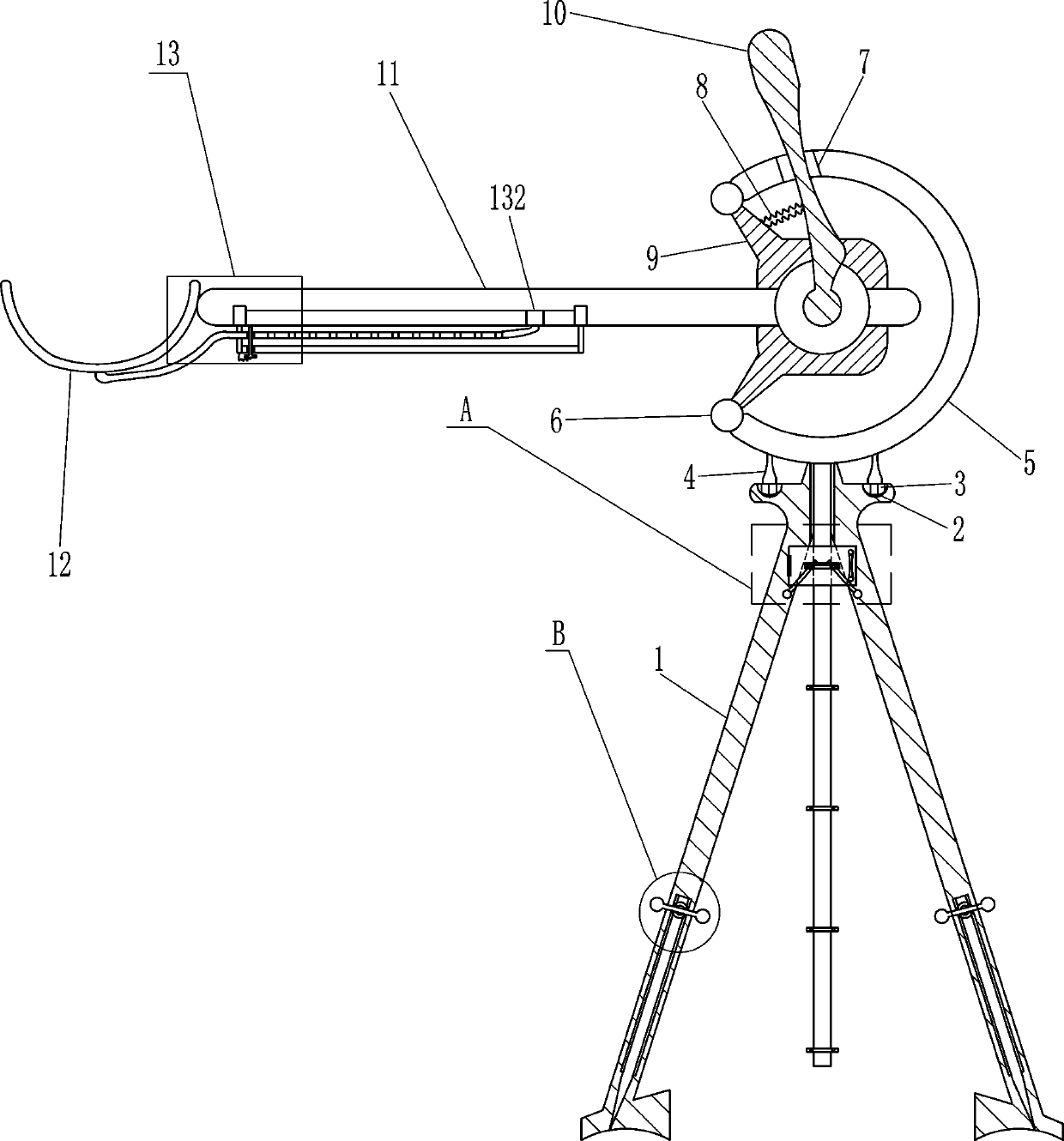

[0017] An aquaculture feeder such as Figure 1-2 As shown, it includes a mounting seat 1, a block 3, a connecting column 4, an arc-shaped slide rail 5, a circular stopper 6, a first slider 7, a first spring 8, a fixed block 9, a first rotating rod 10, Swing bar 11, U-shaped frame 12 and moving mechanism 13, the left and right sides of mounting base 1 top all have the draw-in groove 2 that plays a fixed role, and draw-in groove 2 is provided with block 3, and the top of block 3 is affixed with The connecting column 4 and the block 3 are connected to the connecting column 4 by welding, and the arc-shaped sliding rail 5 is installed between the tops of the left and right connecting columns 4, and the connecting column 4 is connected to the arc-shaped sliding rail 5 by means of bolt connection , both ends of the arc-shaped slide rail 5 are fixed with a circular block 6 that can prevent the first slider 7 from slipping out, and a fixed block 9 is fixed between the upper and lower c...

Embodiment 2

[0019] An aquaculture feeder such as Figure 1-2 As shown, it includes a mounting seat 1, a block 3, a connecting column 4, an arc-shaped slide rail 5, a circular stopper 6, a first slider 7, a first spring 8, a fixed block 9, a first rotating rod 10, Swing bar 11, U-shaped frame 12 and moving mechanism 13, the left and right sides of mounting base 1 top all have the draw-in groove 2 that plays a fixed role, and draw-in groove 2 is provided with block 3, and the top of block 3 is affixed with Connecting column 4, arc-shaped slide rail 5 is installed between the tops of the left and right two connecting columns 4, both ends of arc-shaped slide rail 5 are fixed with circular stoppers 6 that can prevent the first slide block 7 from slipping out, up and down A fixed block 9 is fixed between the two circular stoppers 6, and the front side of the fixed block 9 is rotatably connected with a swing rod 11, and the right part of the front side of the swing rod 11 is fixed with a first r...

Embodiment 3

[0022] An aquaculture feeder such as Figure 1-3 As shown, it includes a mounting seat 1, a block 3, a connecting column 4, an arc-shaped slide rail 5, a circular stopper 6, a first slider 7, a first spring 8, a fixed block 9, a first rotating rod 10, Swing bar 11, U-shaped frame 12 and moving mechanism 13, the left and right sides of mounting base 1 top all have the draw-in groove 2 that plays a fixed role, and draw-in groove 2 is provided with block 3, and the top of block 3 is affixed with Connecting column 4, arc-shaped slide rail 5 is installed between the tops of the left and right two connecting columns 4, both ends of arc-shaped slide rail 5 are fixed with circular stoppers 6 that can prevent the first slide block 7 from slipping out, up and down A fixed block 9 is fixed between the two circular stoppers 6, and the front side of the fixed block 9 is rotatably connected with a fork 11, and the right part of the front side of the fork 11 is fixed with a first rotating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com