A compression shear testing machine

A technology of testing machine and hydraulic cylinder, which is applied in the direction of testing material strength by applying stable shear force and testing material strength by applying stable tension/compression, which can solve the problems that the real stress of rubber bearings does not match.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

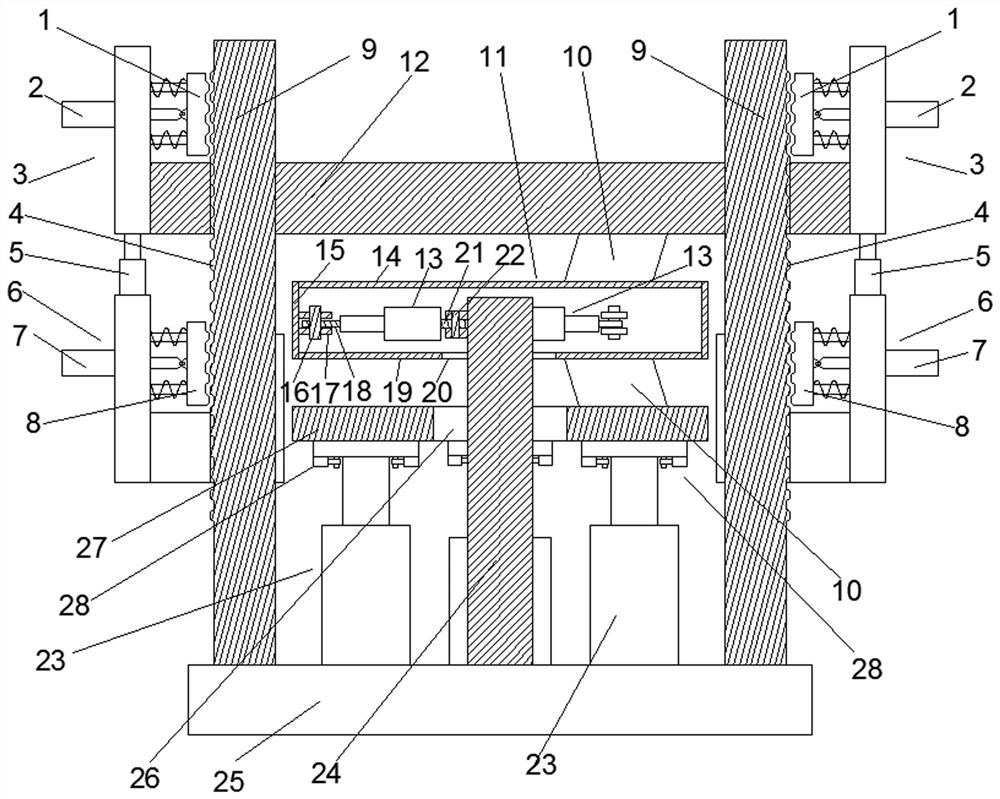

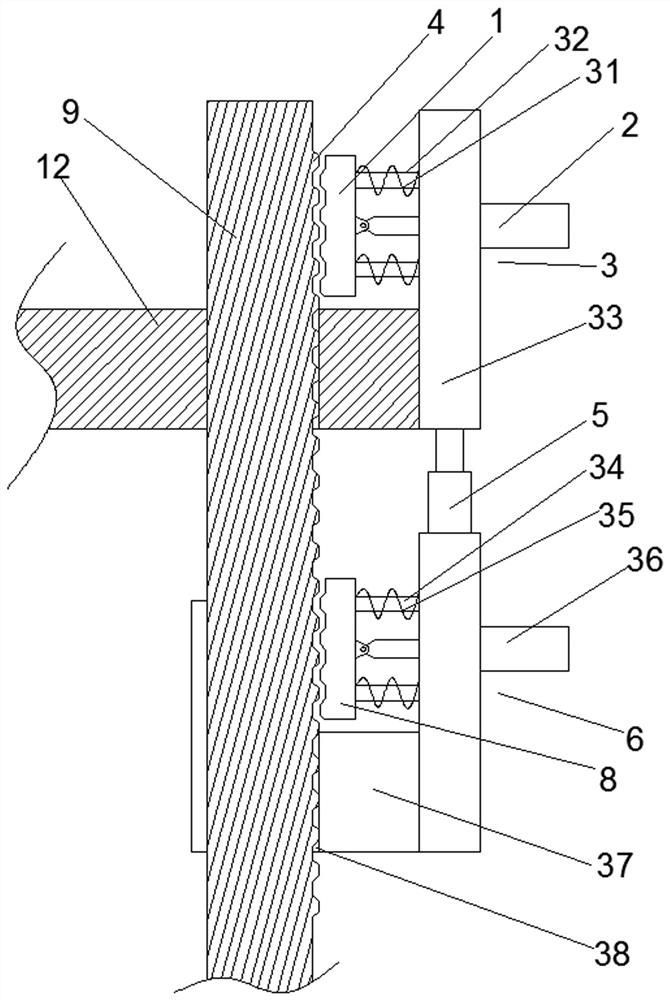

[0023] A kind of embodiment 1 of compression shear testing machine such as Figure 1~6 Shown: comprise the mechanism frame that is provided with vertical loading mechanism, lateral loading mechanism, mechanism frame comprises base 25 and four columns 9 fixed on the base, four columns are divided into left and right pairs, each pair of columns all includes front and rear two The uprights mentioned above. The column is provided with a crossbeam 12, and a beam height adjustment mechanism for adjusting the height of the beam is arranged between the column and the beam. The beam is provided with a column perforation vertically penetrating the beam.

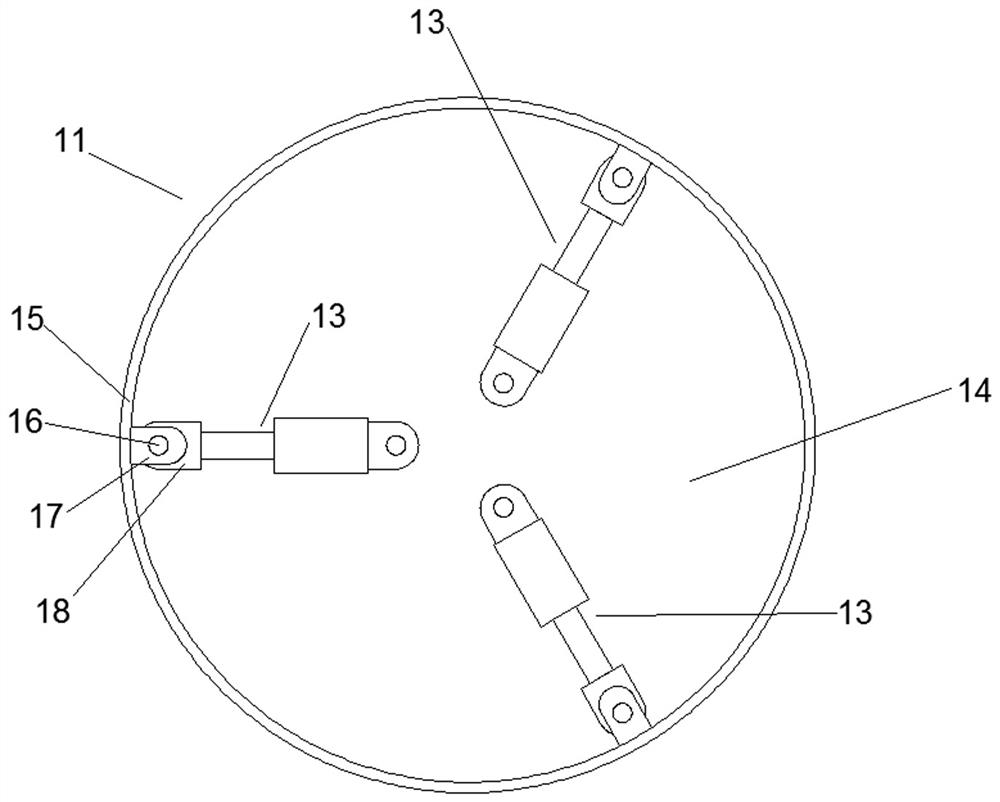

[0024] The compression-shear testing machine also includes an upper side box plate 14 and a lower side box plate 19 for applying a shear box 11 in a horizontal direction to the corresponding rubber bearing 10, and the vertical loading mechanism includes four vertically arranged on the base. The vertical loading cylinder 23, the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com