Protection method for CLTS gray bus for crane beam replacement

A technology of gray busbar and crane beam, which is applied in the protection field of CLTS gray busbar, and can solve problems such as broken cores, economic losses, and system failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

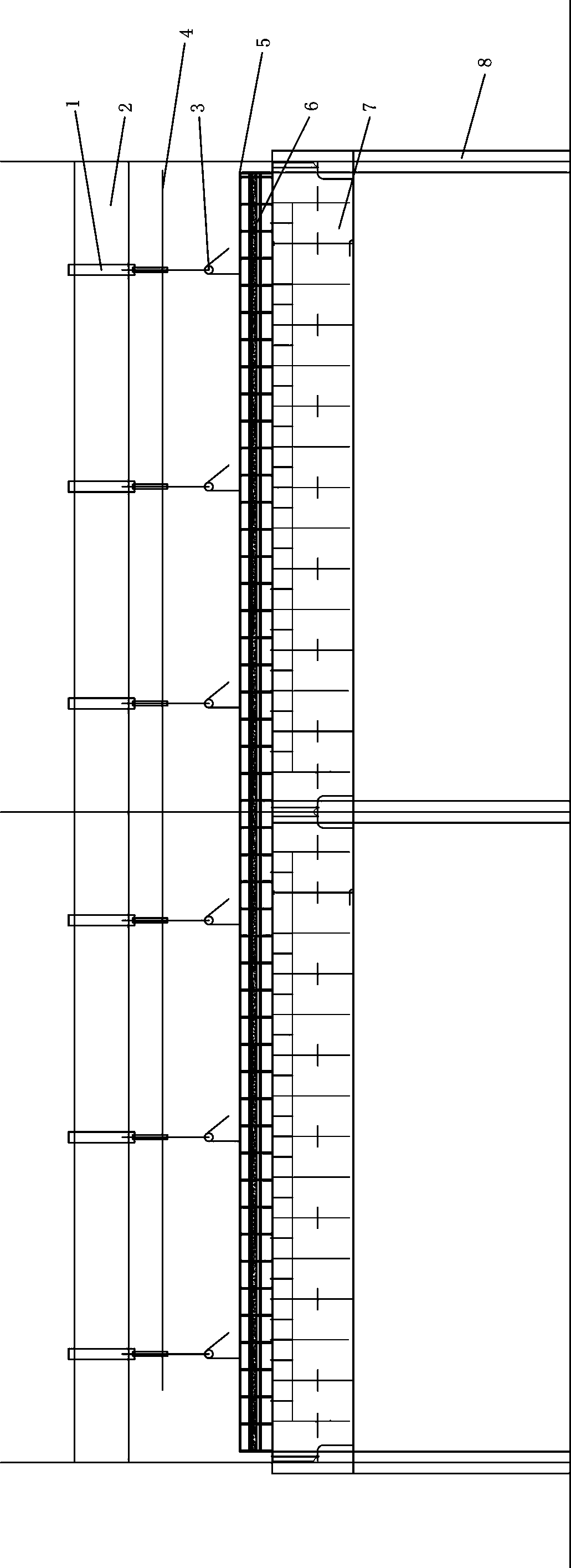

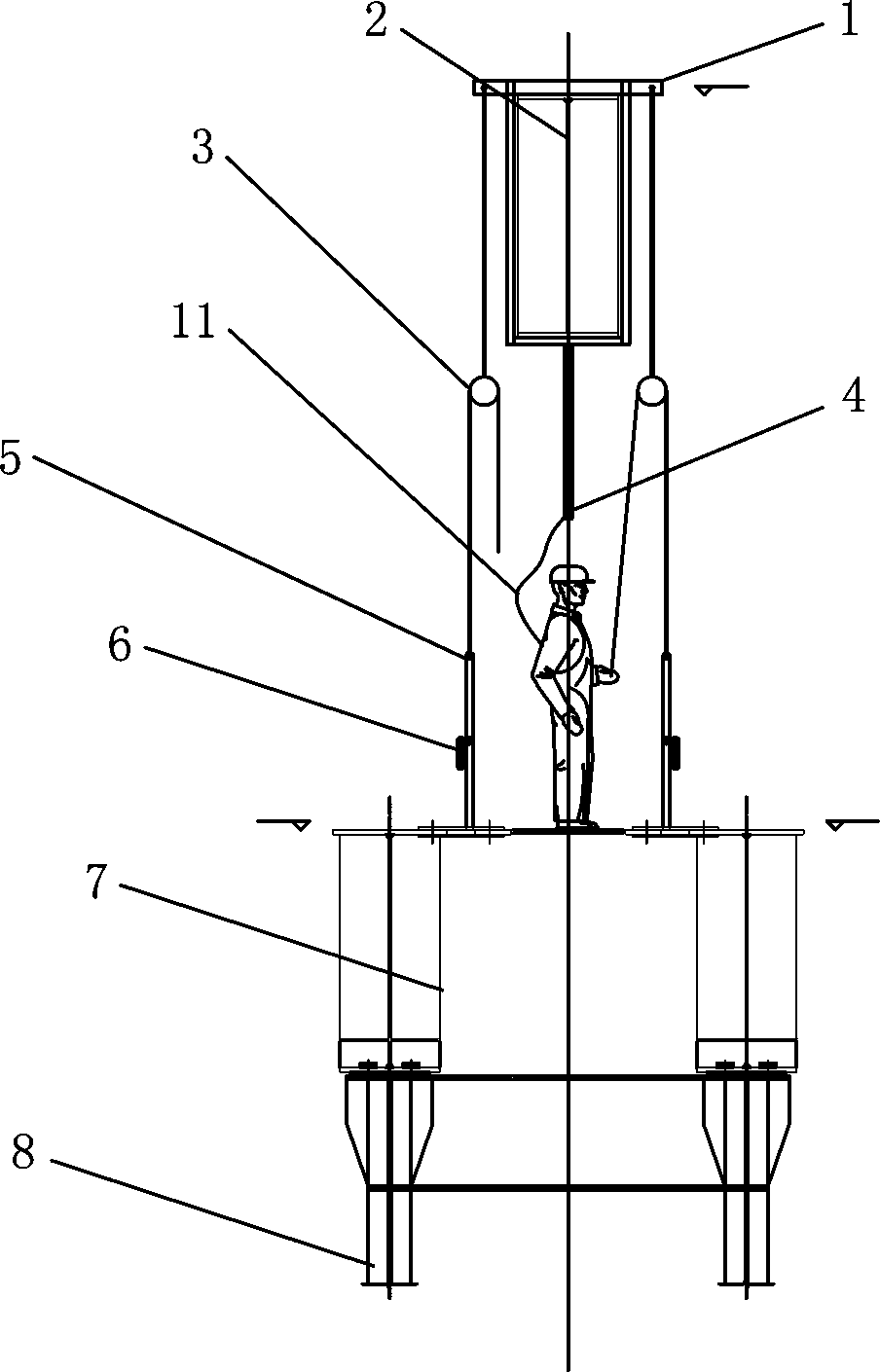

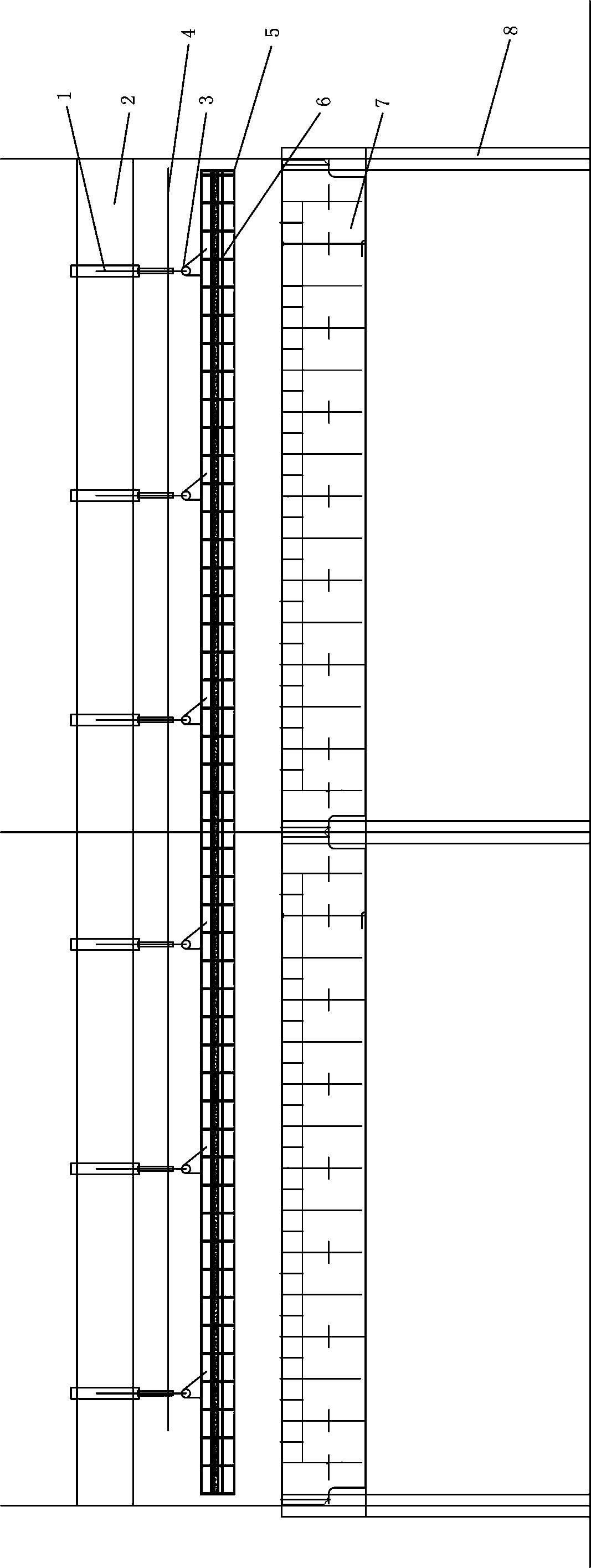

[0028] A protection method for CLTS gray busbars used for crane girder replacement. The factory building column 8 is vertically fixed in the factory building, the crane beam 7 is erected on the factory building column 8 horizontally, and a row of railings are respectively fixed on both sides of the aisle plate on the top of the crane beam 7 5. The gray busbar 6 is fixed on the railing 5, and the factory building beam 2 is erected directly above the crane beam 7. The length and height of the factory building beam 2 are 24m and 2m respectively, and the implementation is carried out in sequence as follows:

[0029] ① Preparation: At least three spreader hangers 1 are fixed on the beam 2 of the factory building. The spreader hangers 1 are straddled on the beam 2 of the factory building. At least three spreader racks 1 are arranged directly above the section crane beam 7, a hole is respectively opened on both sides of the spreader hanger 1 and a spreader 3 is respectively fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com