Transport cage trolley

The technology of a cage car and a side plate is applied in the field of transportation equipment, which can solve the problems of poor folding effect of the cage car, difficult and stable placement, inconvenient folding and reorganization, etc., and achieves the effect of saving space and convenient and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

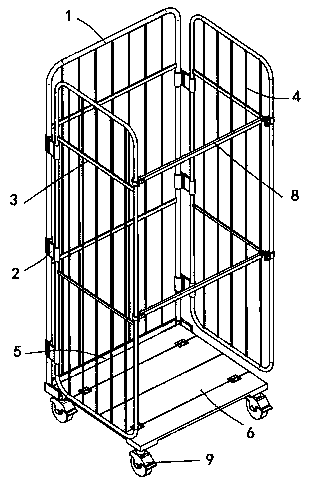

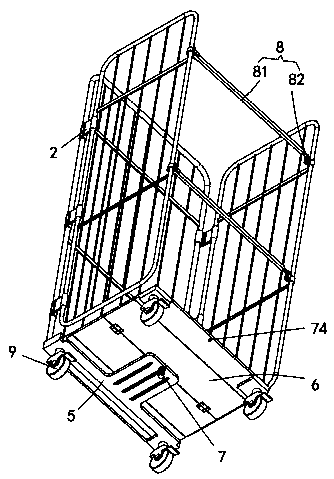

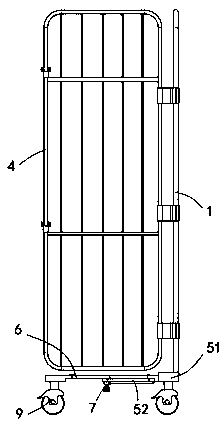

[0036] A kind of transport cage car of the present embodiment, refer to Figure 1-3 : including the first side plate 1, the frame 5 and the bottom plate 6, the two sides of the first side plate 1 are respectively fixedly distributed with the connecting piece 2, and the other end of the connecting piece 2 is respectively rotatably connected with the second side plate 3 and the third side plate; wherein, the two ends of the connecting piece 2 are bushings respectively, and the middle is a connecting rod connecting the two bushings, wherein the connecting rod and the outer wall of the bushing are hinged together, and the bushing at one end is connected to the frame 11 of the first side plate 1 are fixedly connected, and the sleeve at the other end is sleeved on the outside of the second side plate 3 and the third side plate frame 11 . Wherein, the first side panel 1 , the second side panel 3 and the third side panel are all metal grid panels, and the metal grid panels include a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com