Connecting piece in H-shaped steel building

A technology for connecting parts and H-beams, which is used in buildings and building structures, etc., can solve the problems of poor overall building rigidity and low welding point guarantee coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

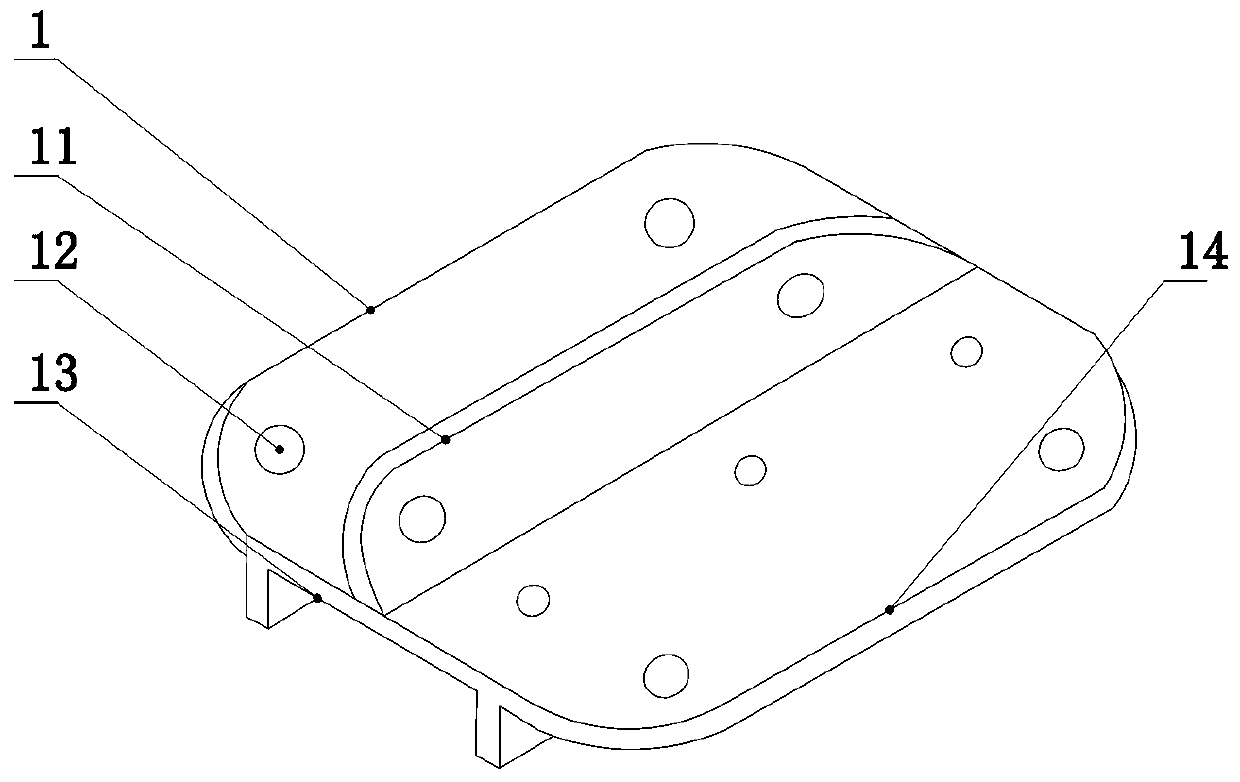

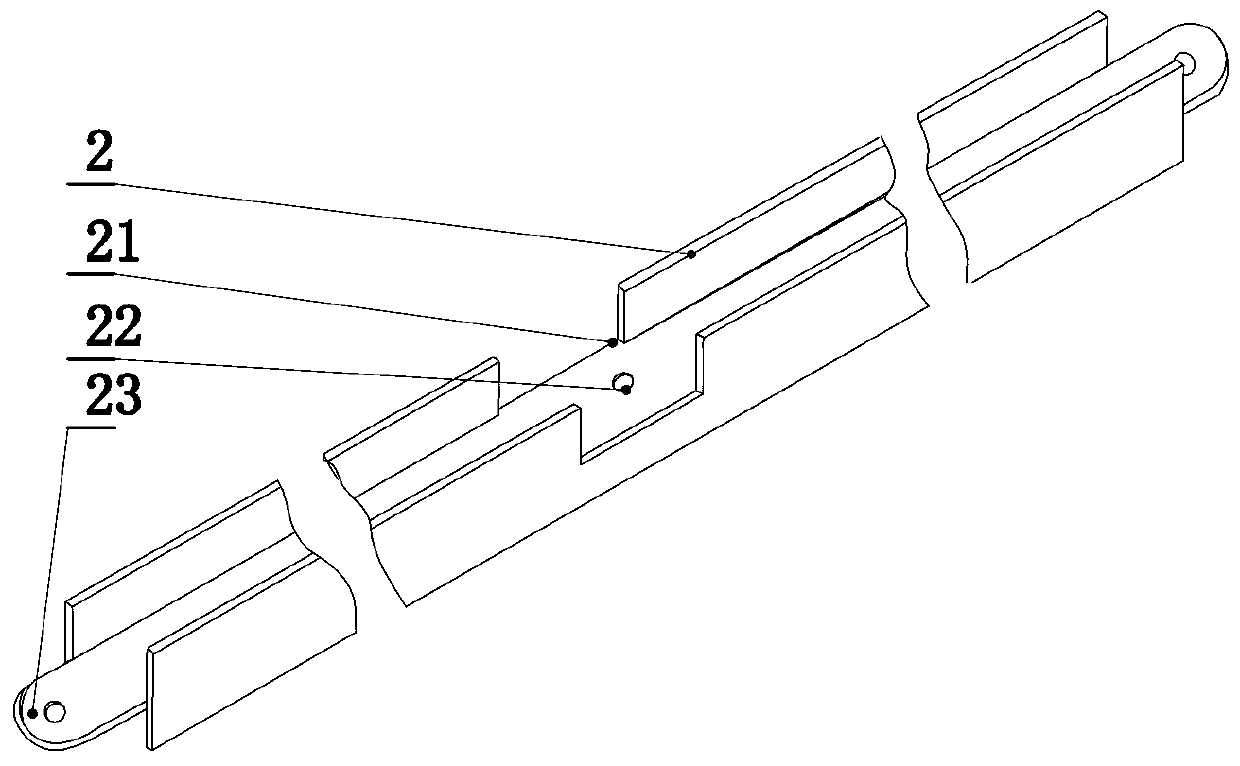

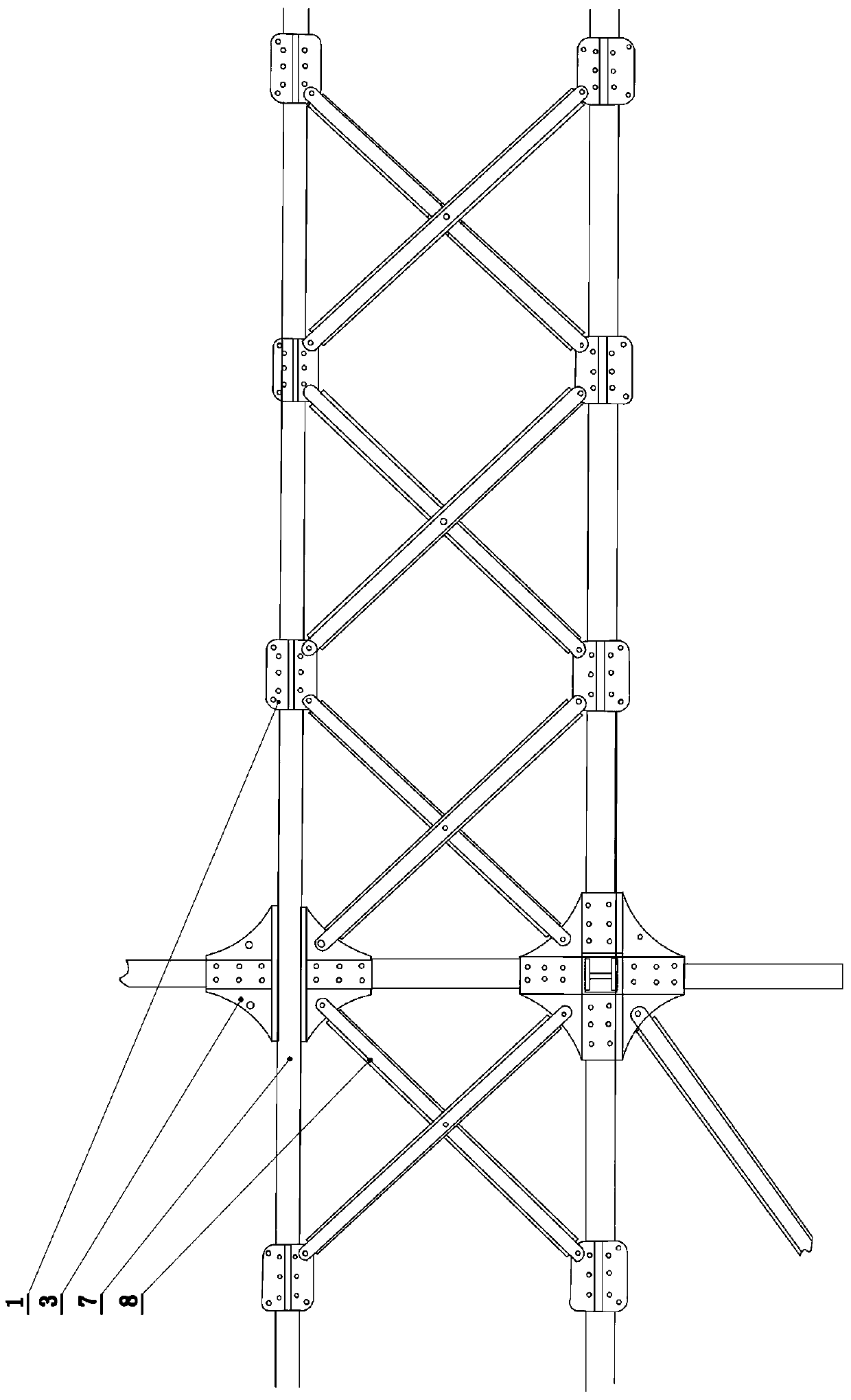

[0019] The fulcrum connectors in the H-shaped steel building are high-grade cast steel materials, which are processed by steel mold casting, forging, heat treatment, and hot-dip galvanizing. H-shaped steel buildings mainly include columns, inclined columns, cross columns, girders, auxiliary beams, side beams, lining beams, connecting beams, etc. The connection methods of the columns mainly include: the support of the top beam column of the vertical column, the support of the inclined column and the outer support of the cross column; Beam end points or lining beam end points are connected and installed with side beams in a T-shape, horizontal side beams are connected and installed at right angles with longitudinal side beams, upright columns are installed up and down in a cross cross with girders and sub-beams, and the outer supports of inclined columns and cross columns are connected and installed. The connecting beams are installed horizontally on the outer sides of the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com